Aggregation sinking and emerging treatment device for oilfield produced waste water

A treatment device and coalescing air flotation technology, which is applied in flotation water/sewage treatment, flocculation/sedimentation water/sewage treatment, grease/oily substance/floating matter removal device, etc., which can solve the increased cost of produced water reinjection treatment , increase the viscosity of the oil-water interface film, and the low compliance rate of water injection water quality, etc., to achieve the effects of saving water treatment chemicals, enhancing the treatment effect, and high recycling value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

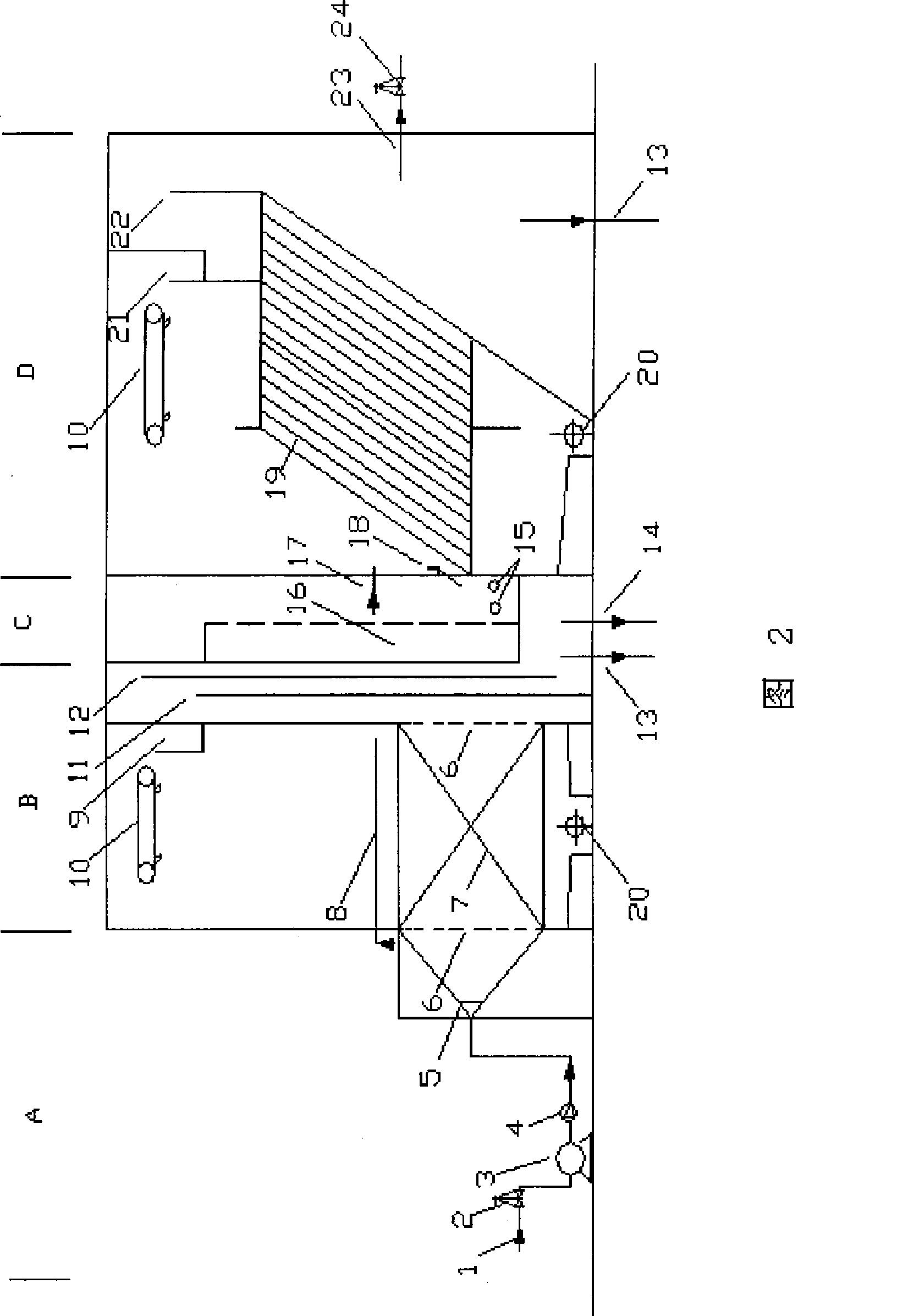

[0020] Example 1:

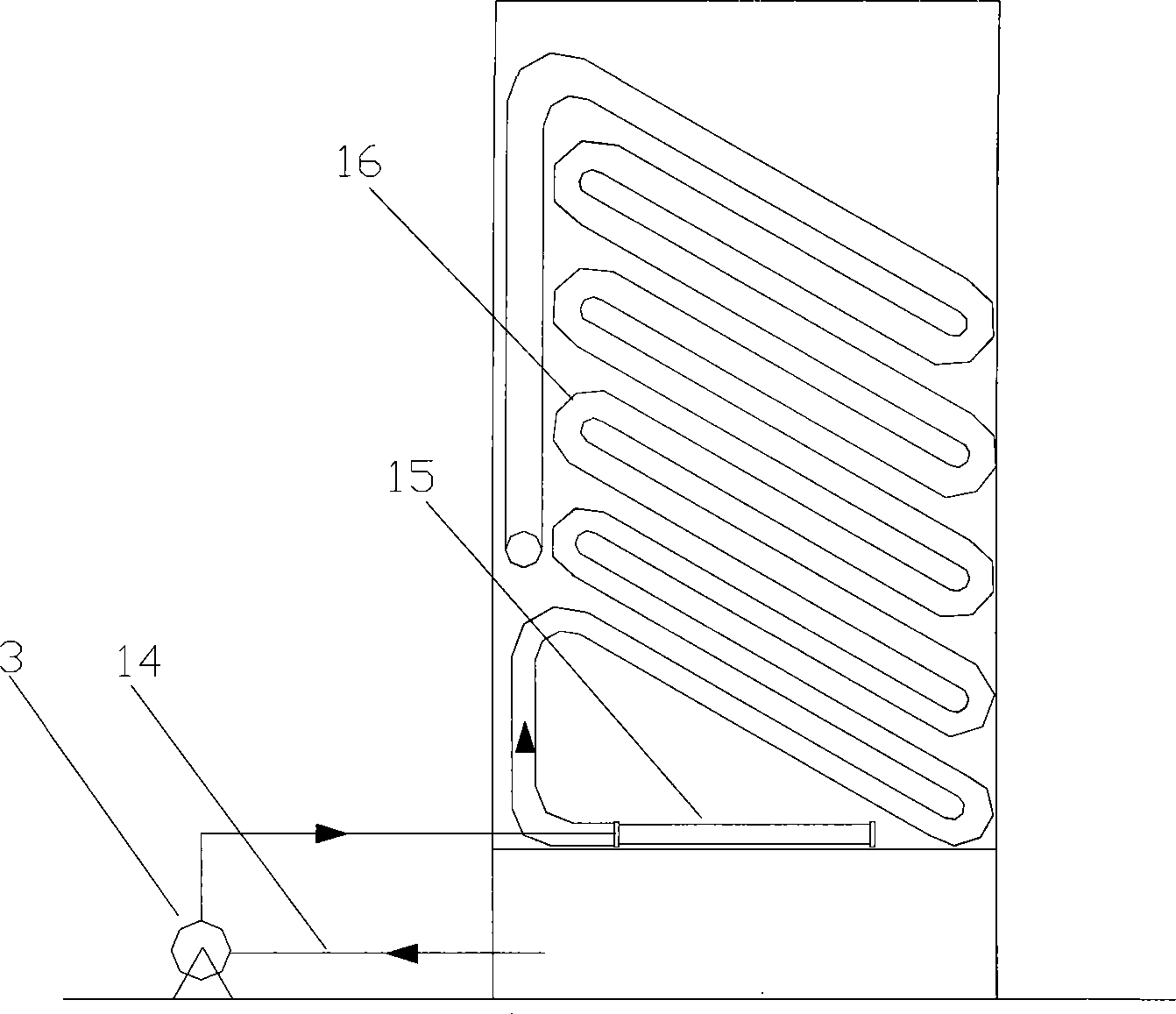

[0021] As shown in Figure 1, the present invention includes a tank body, water inlet section A, coalescing air flotation section B, dosing mixing reaction section C and air flotation sedimentation and slag removal section D, sewage through the water inlet pipe 1, inlet The water valve 2, the water inlet pump 3, the electronic flow meter 4 are pumped into the conical buffer hopper 5 through the water inlet pump. The sewage flows into the egg tray type coalescing packing layer 7 of the coalescing air flotation section B evenly from the liquid distribution wall 6, and the sewage Crude oil is coalesced by the filler to form oil droplets that float up. After passing through the filler layer, the crude oil is combined with the air bubbles released by the perforated cloth air pipe 8 and quickly rises to the water surface under the action of the air bubbles. In the other slop tank, the degreasing sewage flows from another liquid distribution wall through the overflow plat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap