Precision filter

A precision filter and filter technology, which is applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., can solve the problems of poor filtering effect, deviation of measurement results, and affecting the accuracy of sensors, etc., so as to achieve convenient use, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

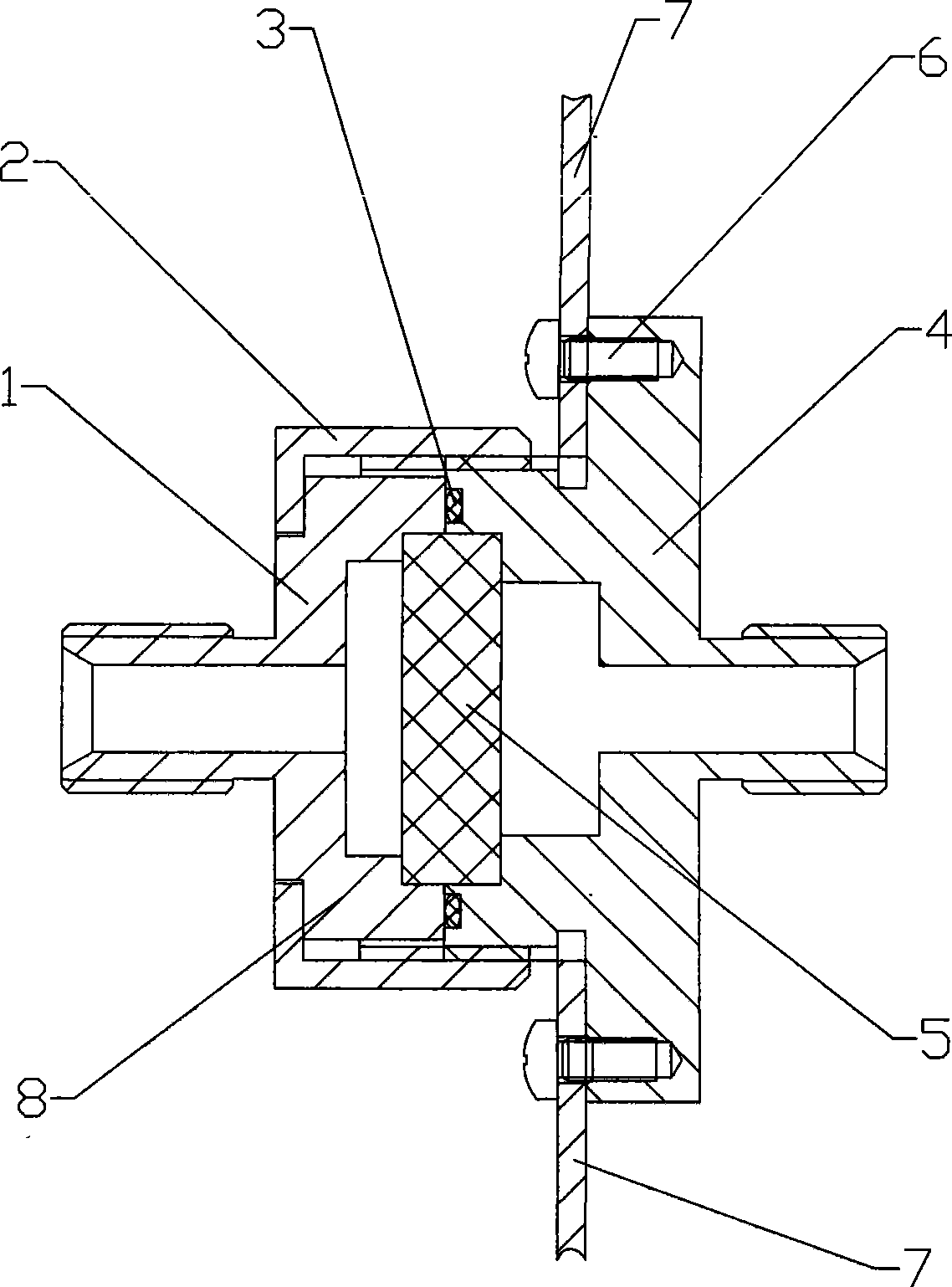

[0011] Examples such as figure 1 As shown, a precision filter includes a filter cover 1 and a filter base 4. The filter cover 1 has a boss 8, the filter cover 1 and the filter base 4 are connected, and the filter base 4 has external threads. A round nut 2 is arranged between the filter cover 1 and the filter base 4, and the round nut 2 connects the filter cover 1 and the filter base 4 through the boss 8 and the external thread, and the filter cover 1 and the filter base 4 is provided with a filter element 5, the filter element 5 is made of polymer sintered polytetrafluoroethylene, the contact between the filter cover 1 and the filter base 4 is provided with an O-shaped gasket 3, and the filter base 4 is passed through the bolt 6 is fixed on the fixed plate 7.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap