Novel high-efficient energy-saving pump

A new type of high-efficiency, energy-saving technology, applied to pumps, pump components, non-variable pumps, etc., can solve the problems of large gap leakage loss, short seal ring life, low efficiency, etc., to achieve good sealing performance, improved pump efficiency, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

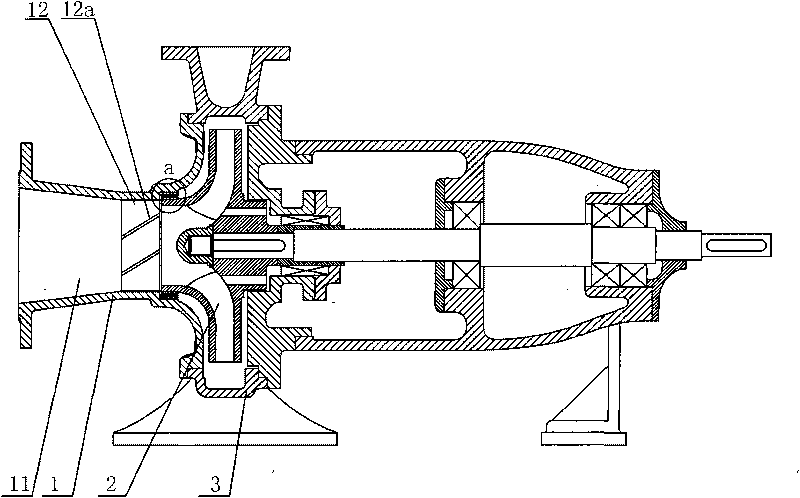

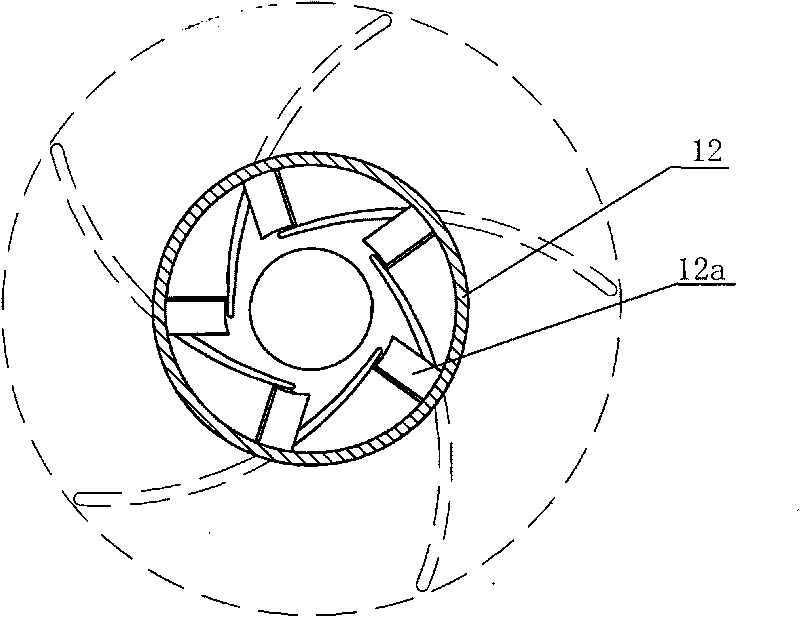

[0021] Reference Figure 1-7 , A new type of high-efficiency and energy-saving pump, including suction chamber 1, impeller 2, pump body 3, pump body sealing ring 4, impeller sealing ring 5 and other common components, the suction chamber 1 by the straight cone-shaped suction chamber 11 and its outlet end straight The pipe section 12 is composed of two parts, and the straight pipe section 12 is provided with an inclined partition plate 12a.

[0022] The inclination direction of the partition 12a is consistent with the rotation direction of the impeller 2.

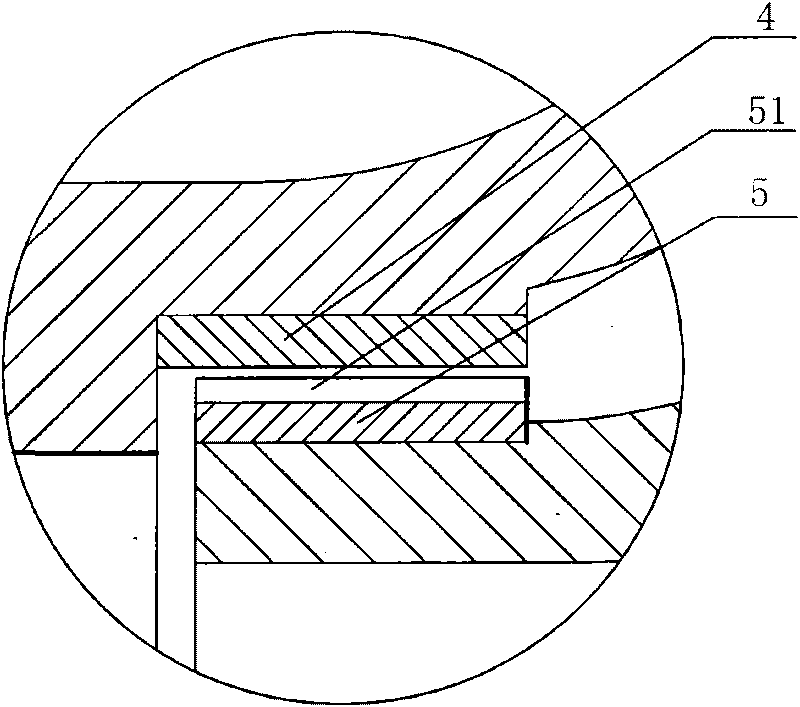

[0023] Diversion grooves 51 are evenly distributed on the outer surface of the impeller sealing ring 5 in the circumferential direction.

[0024] The pump body 3 is attached with an elongated tongue 31, and the small gap between the inner surface of the elongated tongue 31 and the outer circular surface of the impeller 2 generates greater resistance and forms a throttle arc surface 31a; The contour line of the partition tongue 31 is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap