Windscreen wiper wiping angle measuring apparatus and measuring method thereof

A technology of angle measurement and measurement method, applied to measurement devices, instruments, optical devices, etc., can solve the problems of deviation in the design value of the wiper angle, inability to measure the wiper angle of the wiper, and inability to measure the wiper, and reach the applicable range. Broad, accurately measured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

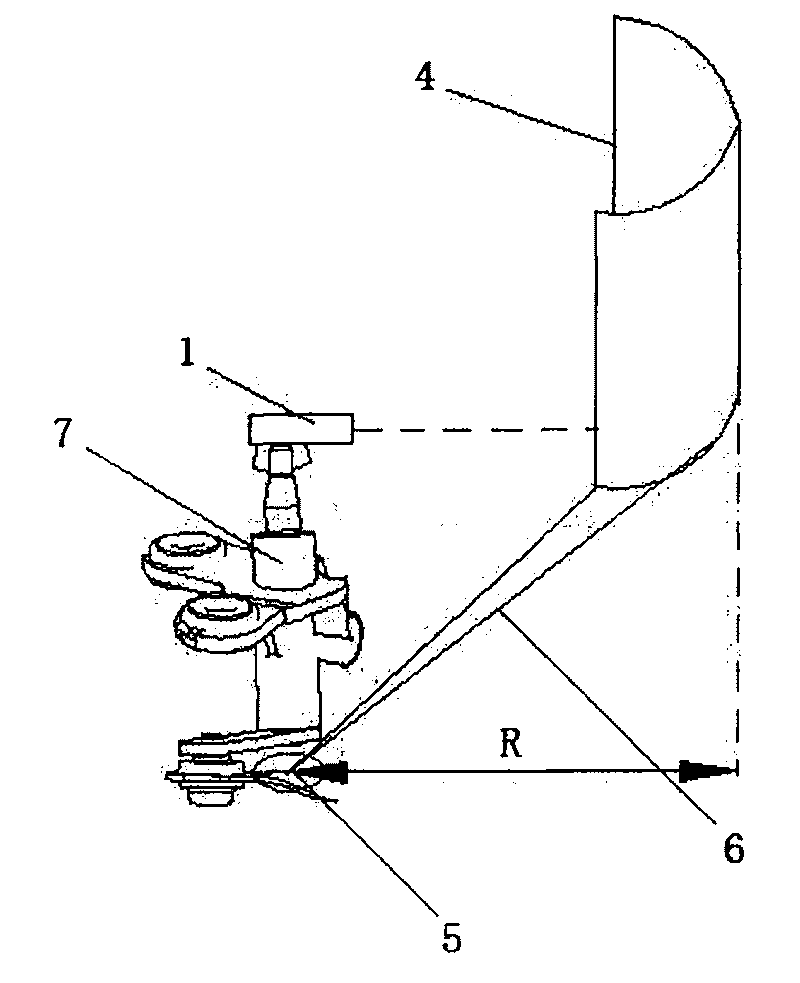

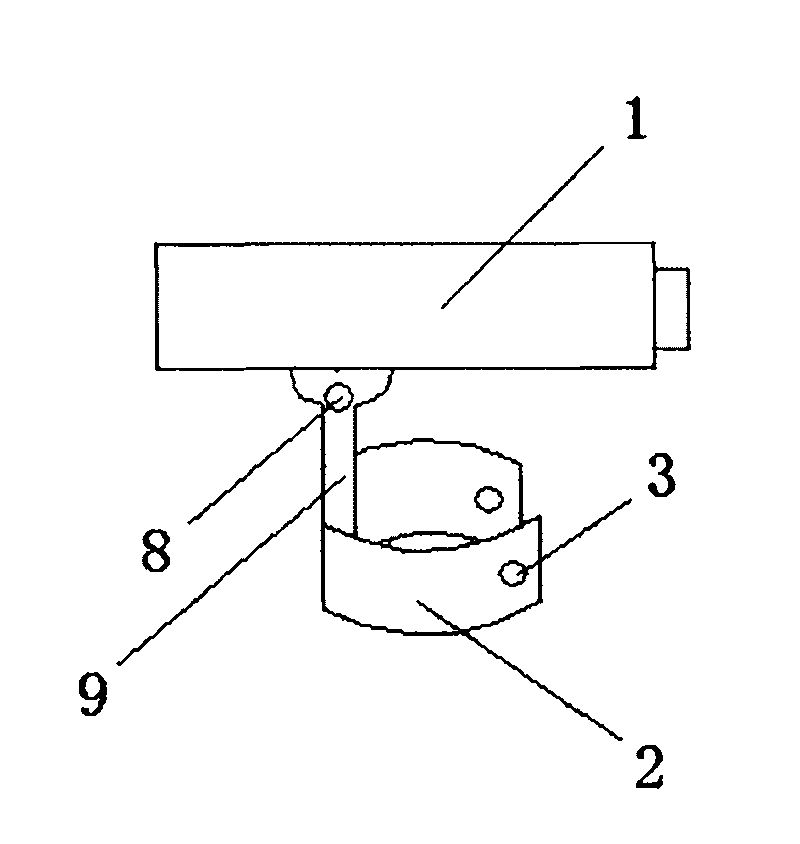

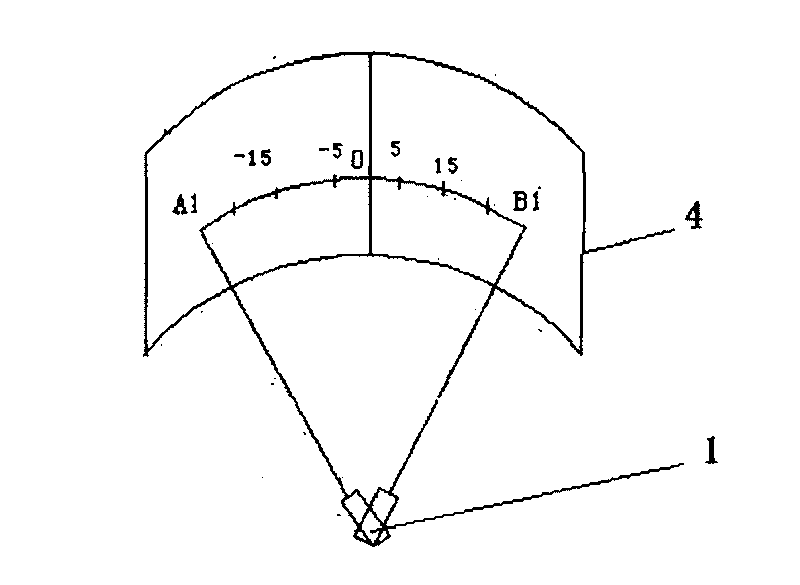

[0024] Such as figure 1 , 2 As shown, the wiper angle measuring instrument of the present embodiment includes a visible laser emitting probe 1 and an arc dial 4, and the visible laser emitting probe 1 is provided with a fixing device for fixing it to the output shaft 7 of the wiper to be tested. Clip, the fixed clip includes two arc-shaped pieces 2, these two arc-shaped pieces 2 are fixedly connected with a pole 9, the head end of the pole 9 is installed on the visible laser emitting probe 1 through an adjustable nut 8 On the side, the free ends of the two arcuate plates 2 are provided with bolt holes 3; the arcuate dial 4 is provided with a bracket for fixing, and the bracket includes a tray 5 and a bracket for fixing the arcuate dial 4 and the tray 5 Two oblique bars 6, the tray 5 is provided with a mark point, and the mark point is located on the axis of the circle center corresponding to the arc surface of the arc dial 4 (mark points are not drawn in the figure), that is, th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap