Heating control cabinet of high-frequency hot roll

A heating control, high-frequency technology, used in induction heating, induction heating devices, cooling/ventilation/heating transformation, etc., to achieve good heat dissipation, avoid damage and pollution, and simple installation and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

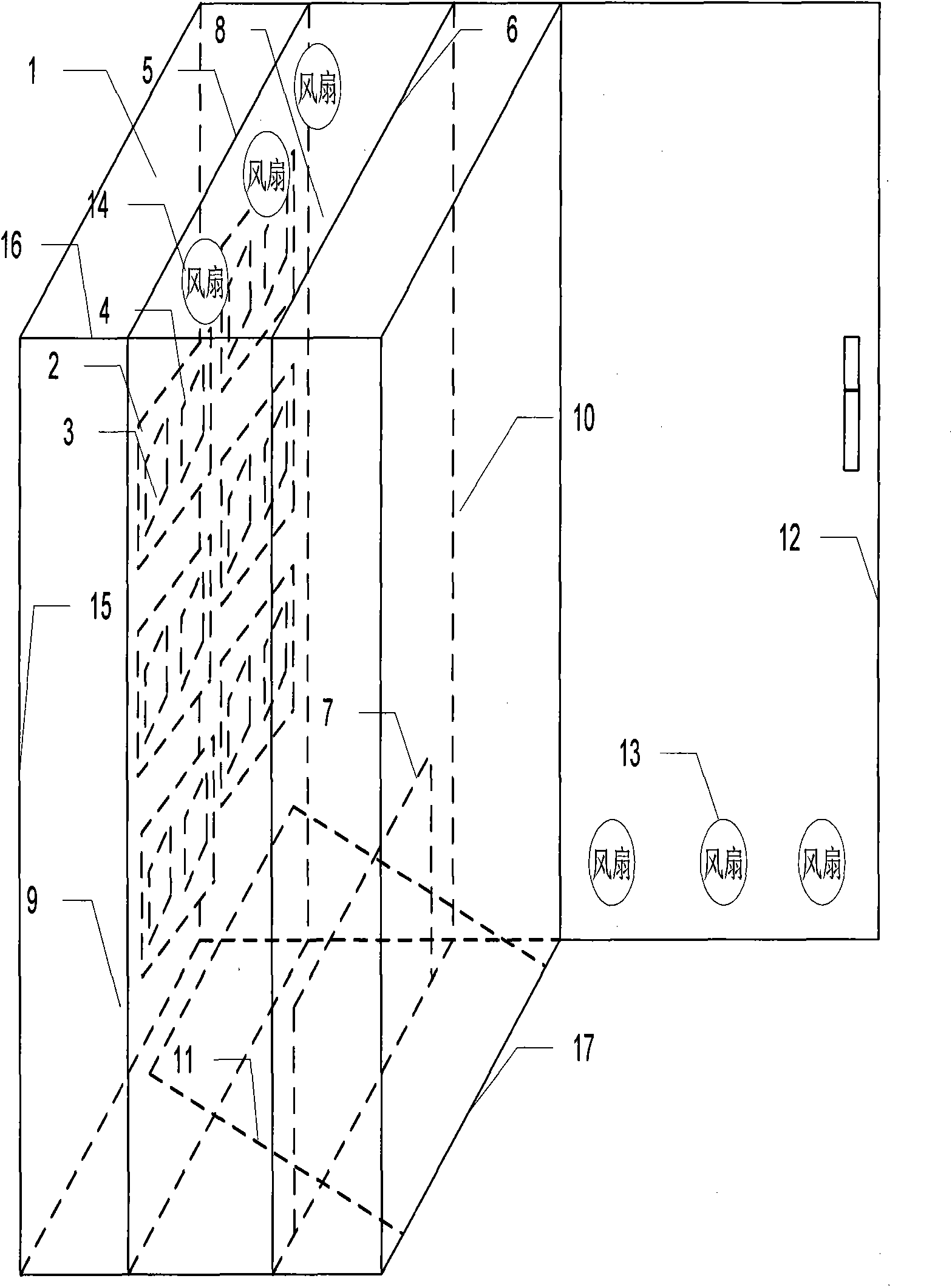

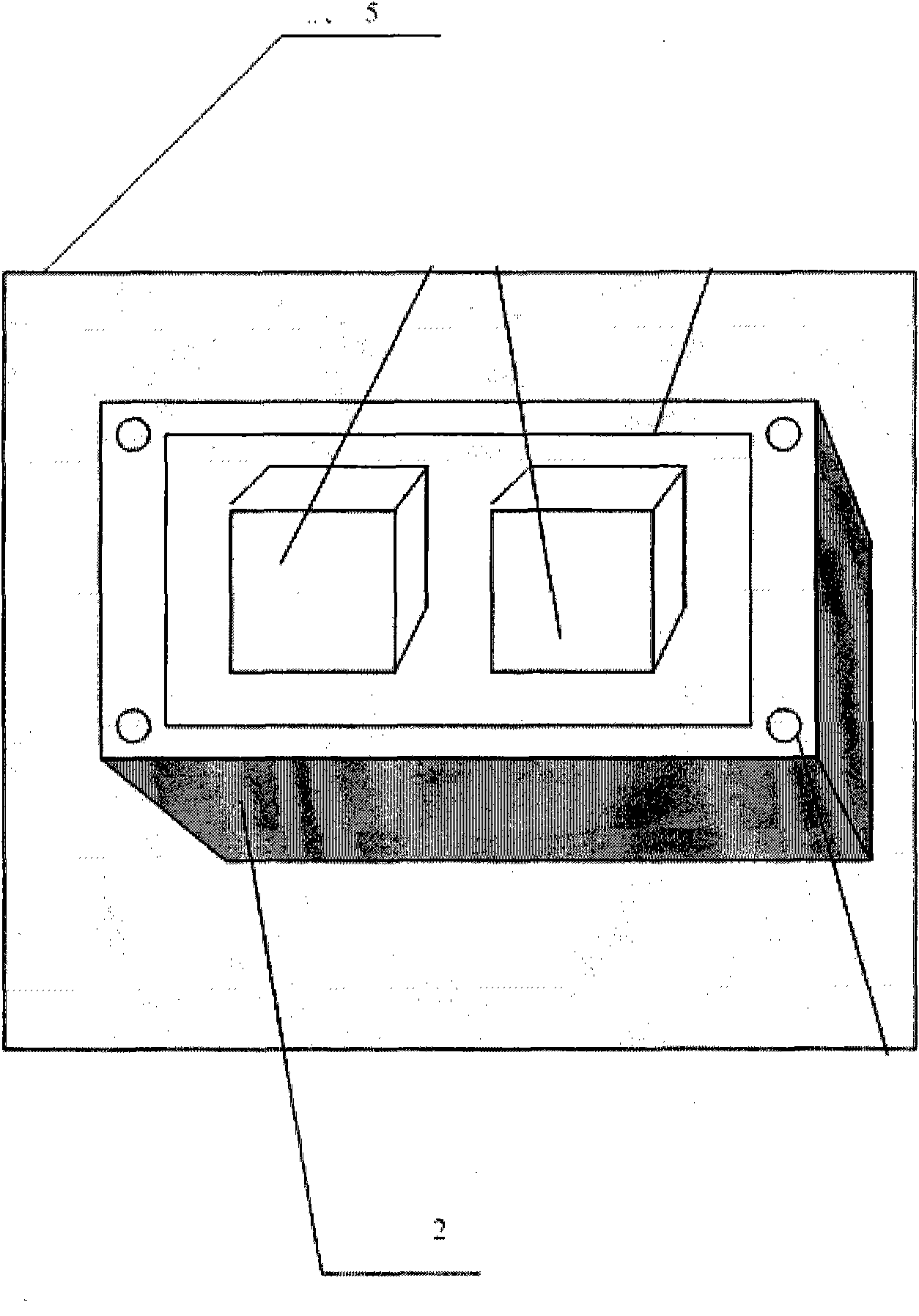

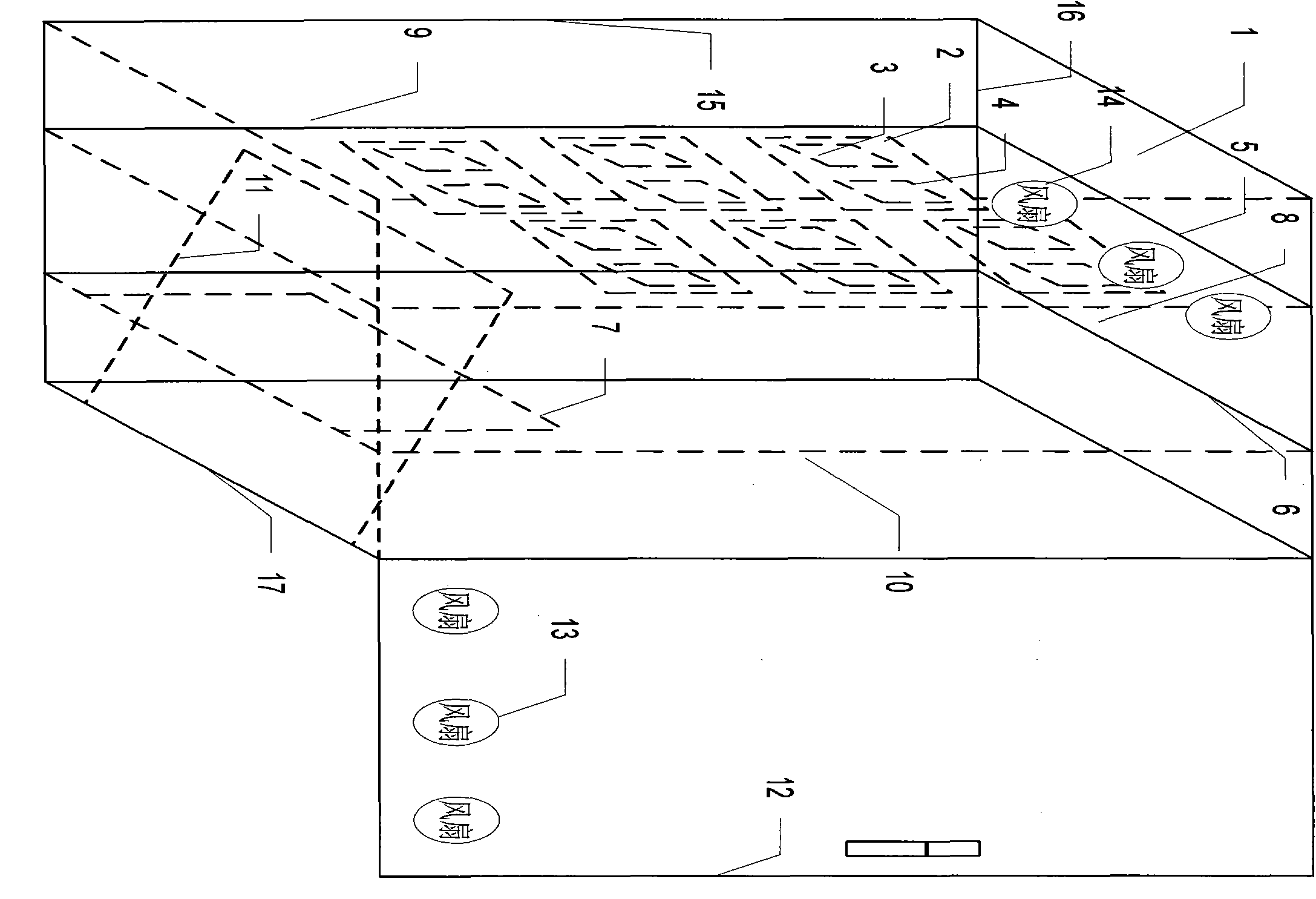

[0028] figure 1 In the cabinet 1, there are an inner heat dissipating metal plate 5 and an outer heat dissipating metal plate 6 for installing various devices. The inner heat dissipating metal plate 5 is equipped with 6 aluminum heat dissipation blocks for IGBT devices. The aluminum heat dissipation block 2 is One of them, the aluminum heat sink is in the gap 8 formed by the heat dissipation metal plates 5 and 6, the IGBT devices 3 and 4 are in the gap formed by the heat dissipation metal plate 5 and the cabinet door 15, at the position of the IGBT devices 3 and 4, The heat dissipating metal plate 5 has two through holes of the same size as the IGBT device, and the IGBT devices 3 and 4 are mounted on the aluminum heat sink 2 through the through holes. The side walls 9 and 10 of the cabinet body seal the gap 8 from two sides. The outer heat dissip

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap