Metal floor buckle

A metal floor and buckle technology, which is applied in the field of building decoration materials, can solve the problems of inability to install floors with different thicknesses, increase the cost of floor installation, and limit the scope of use, so as to reduce the construction cost of floor paving, reduce Variety and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

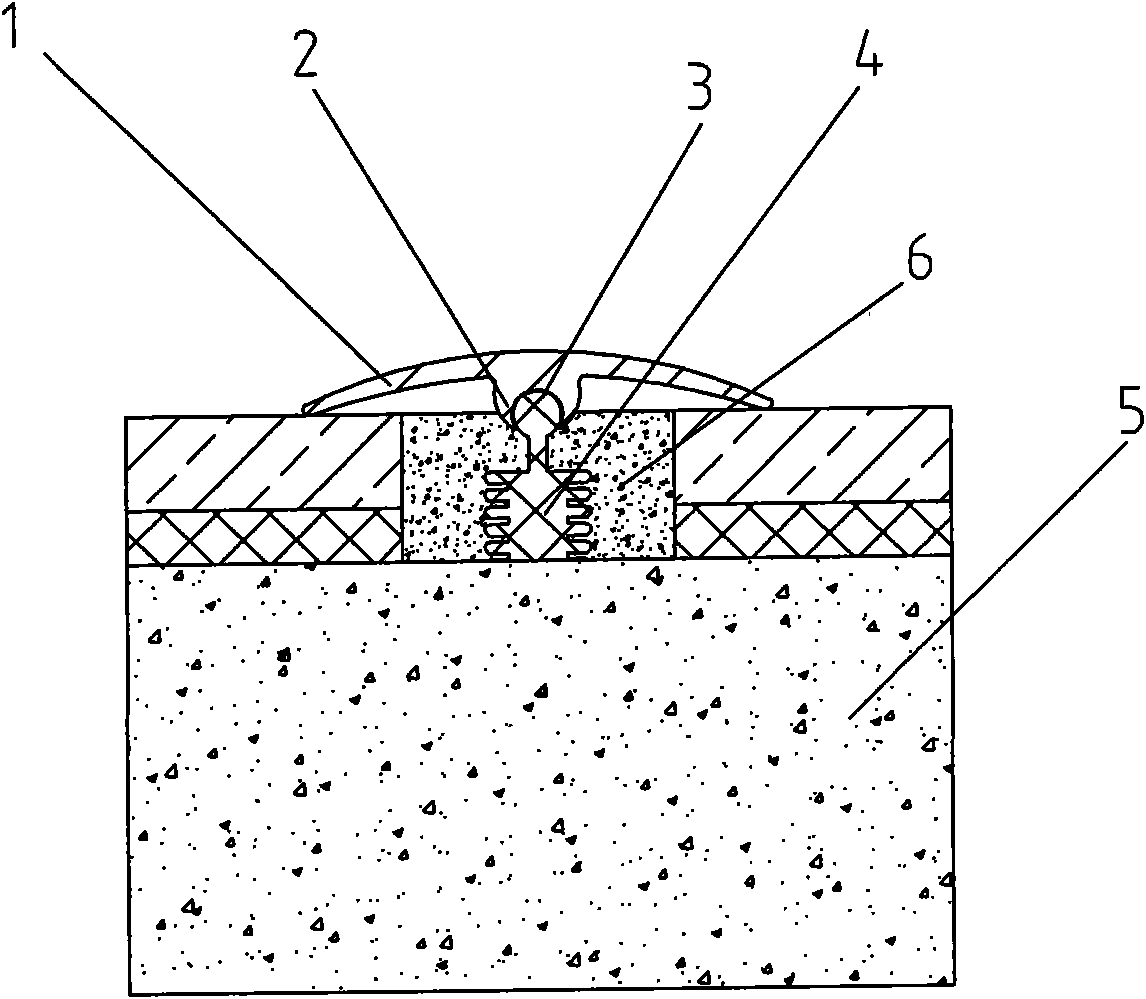

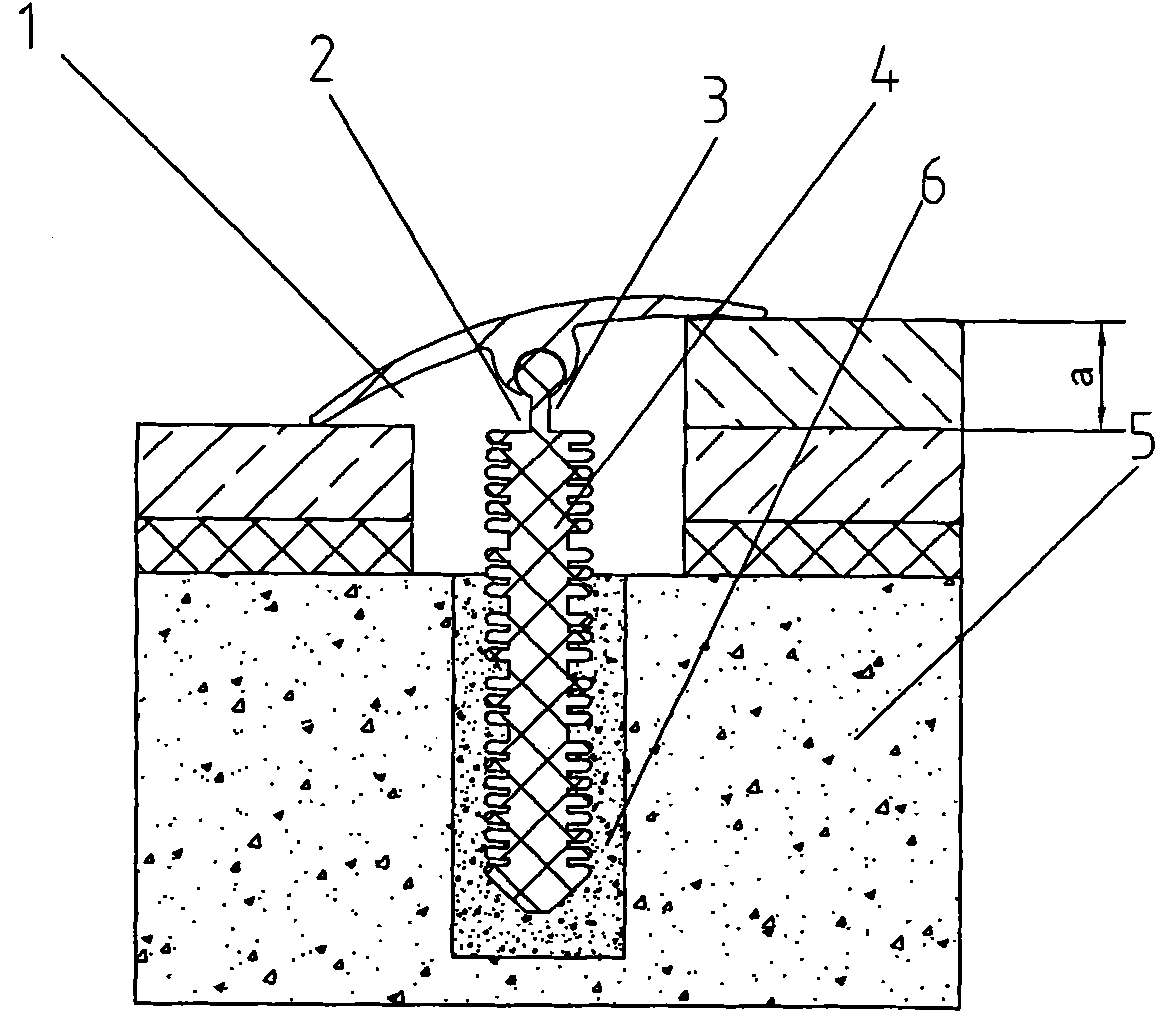

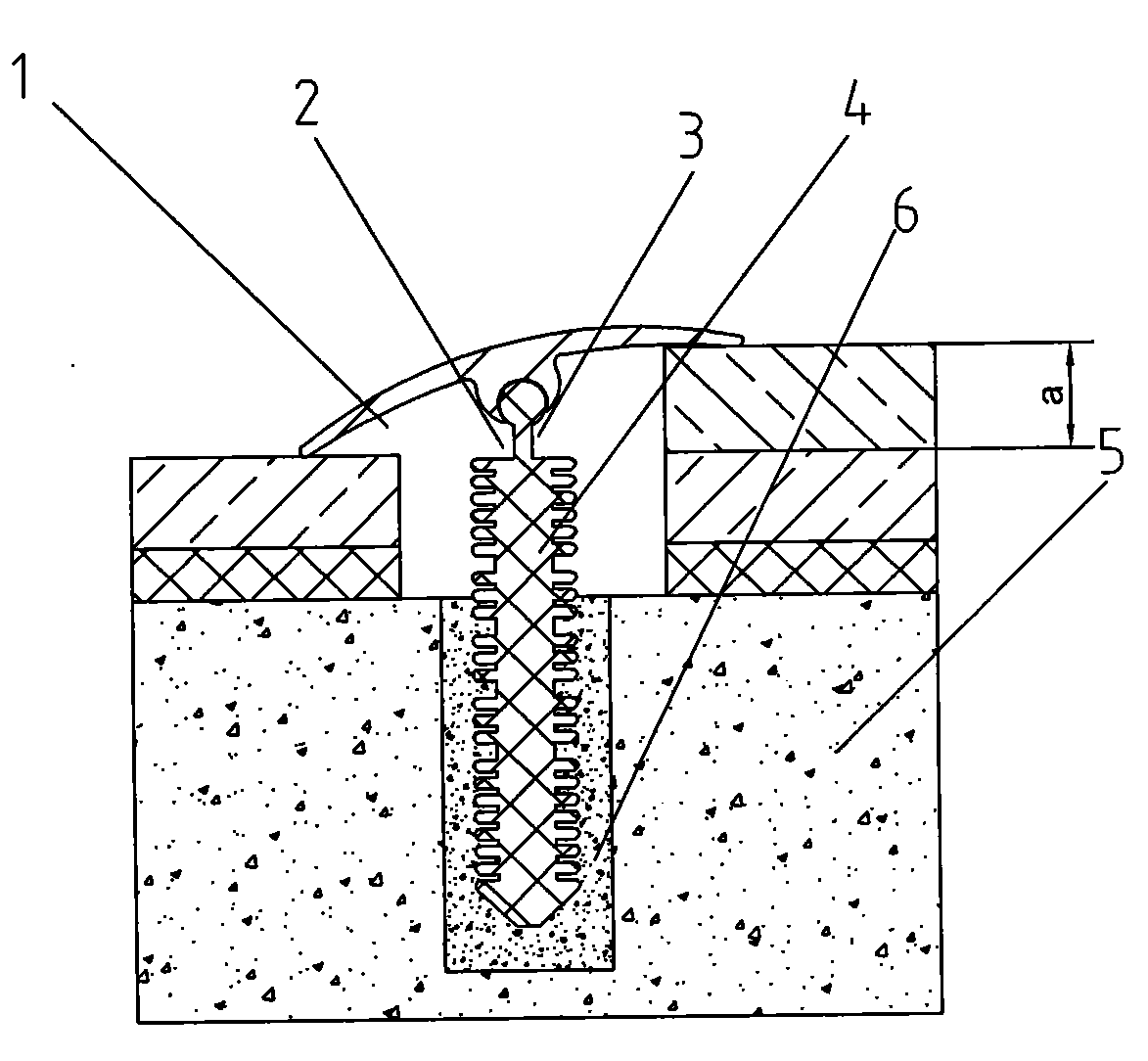

[0014] Such as figure 1 , figure 2 As shown, the present invention includes the upper top surface 1 of the buckle extending to both ends, and the lower groove 2 of the buckle that is arranged on the inner side of the upper top surface of the buckle and is equal to the length of the buckle. The upper top surface 1 of the buckle of the present embodiment is It is arc-shaped, and the contact area between the two sides of the arc and the floor is small, and the compacting effect on the floor is good. The cross-sectional shape of the groove 3 of the lower groove 2 of the buckle is arc-shaped, and the shape of the groove 3 matches the shape of the cylindrical head of the special injection screw 4, and the arc shape of the groove 3 is larger than a semicircle.

[0015] Such as figure 1 As shown, when the present invention is installed, the injection molding screw 4 that can b

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap