Vehicle suspension

A vehicle and vehicle body technology, applied in vehicle components, suspension, elastic suspension, etc., can solve the problems of deterioration of vehicle vibration reduction performance, poor vibration reduction effect, limited vibration reduction effect, etc., and achieve the change of vehicle suspension stiffness coefficient and damping. The effect of coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

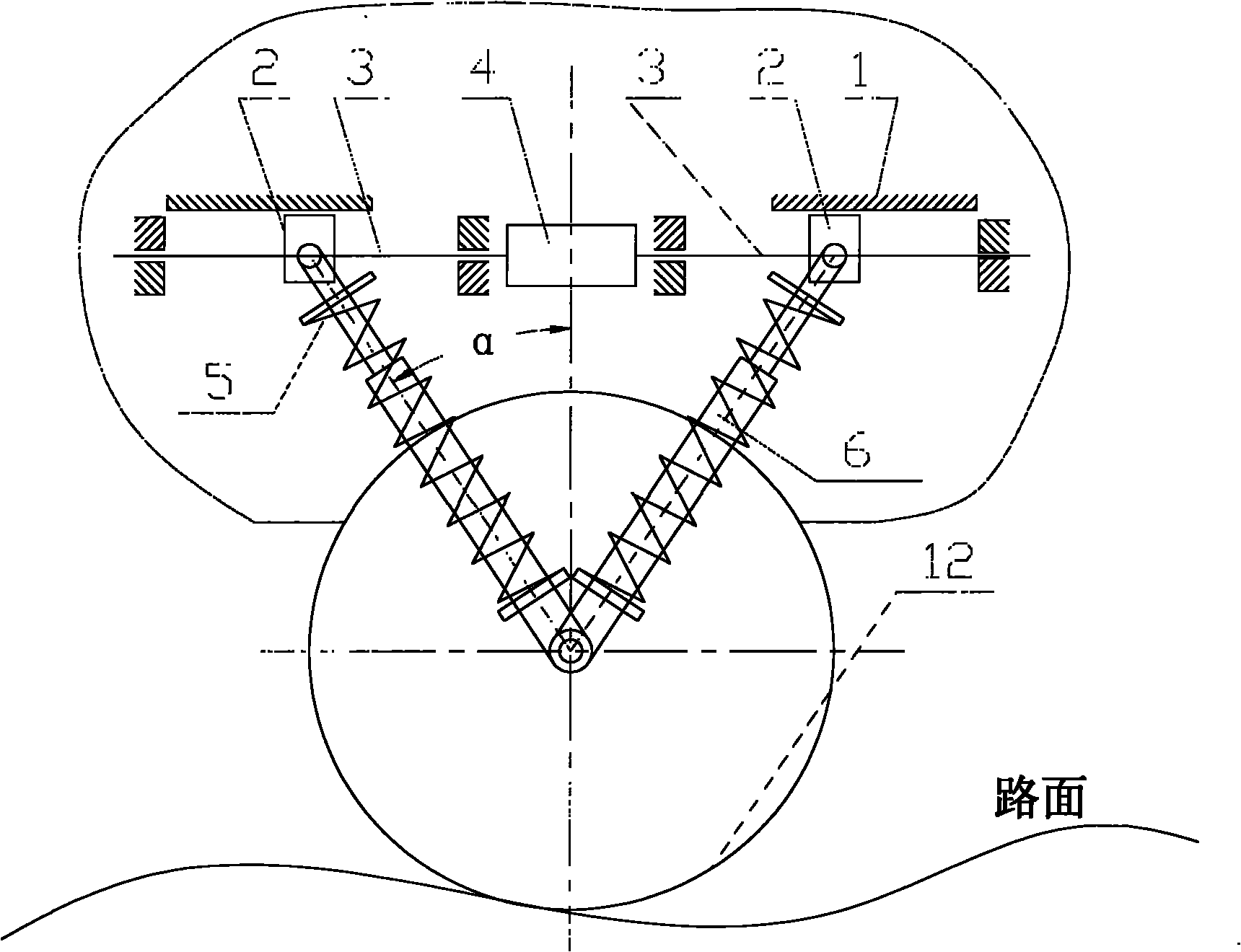

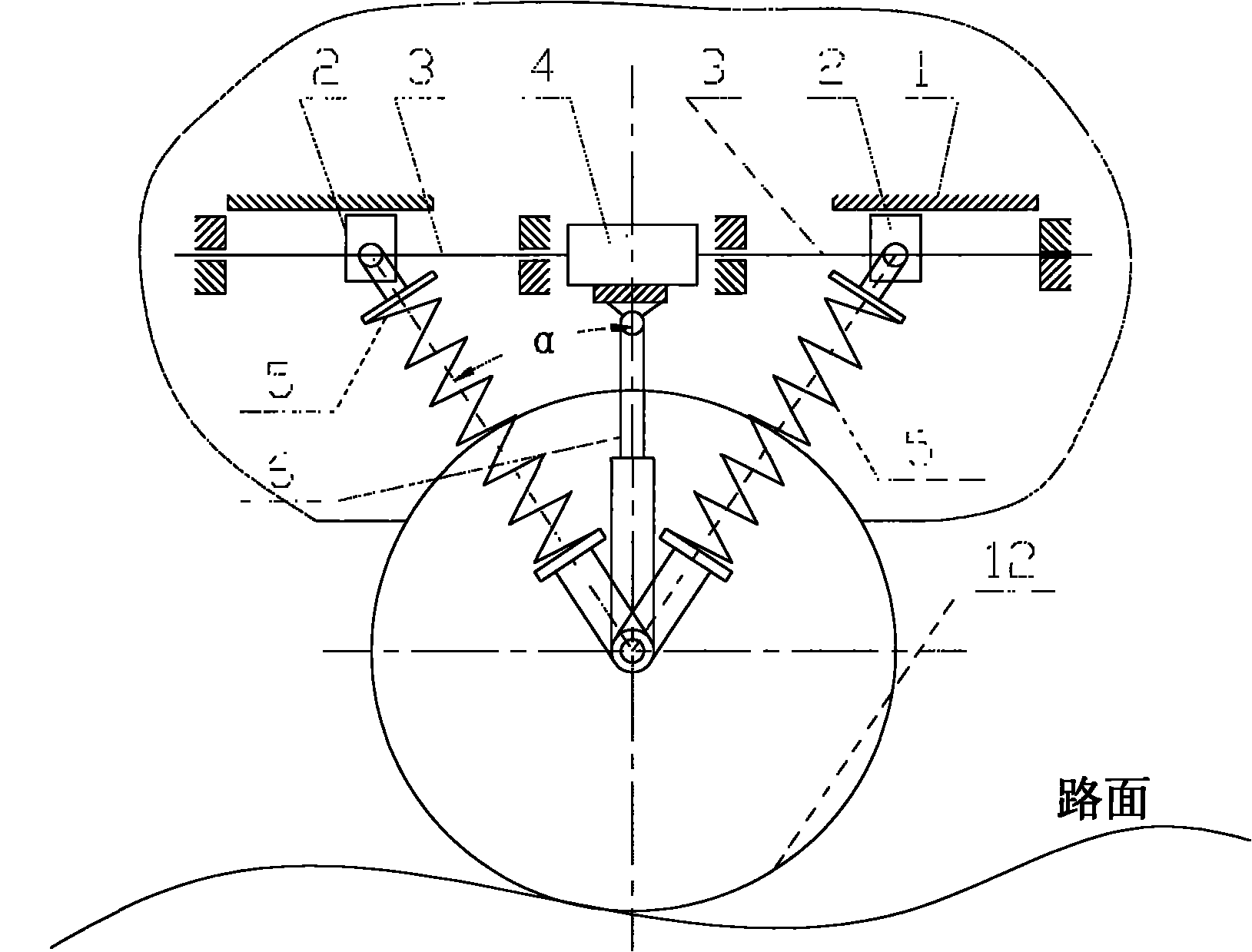

[0023] figure 1 It is a schematic diagram of the scheme of the present invention, such as figure 1 As shown, the vehicle suspension of the present invention includes a vehicle body 1, a nut 2, a screw rod 3, a motor 4, a spring 5, a shock absorber 6, a hub 7, and a wheel 12. It is characterized in that: each suspension assembly uses a motor 4 and two screw mechanisms arranged symmetrically; the rotating shaft of the motor 4 is coaxial with the screw rod 3 .

[0024] It is also characterized in that the suspension assembly is arranged in the front and back directions.

[0025] It is also characterized in that each suspension assembly uses two pairs of shock absorbers 6 and springs 5, each pair of shock absorbers 6 and springs 5 are coaxial and axisymmetric, and the upper end is connected to the nut 2 of the screw mechanism with a pin, and the lower e

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap