Connection fitting and application thereof

A technology for connecting accessories and connecting components, which is applied in the direction of connecting components, rods, mechanical equipment, etc., and can solve problems such as deformation, fracture, and device failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

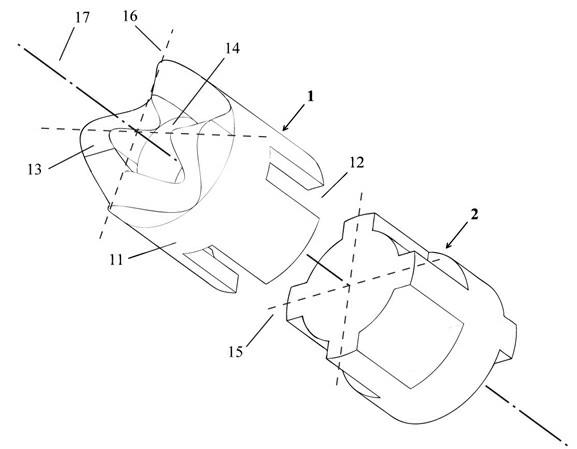

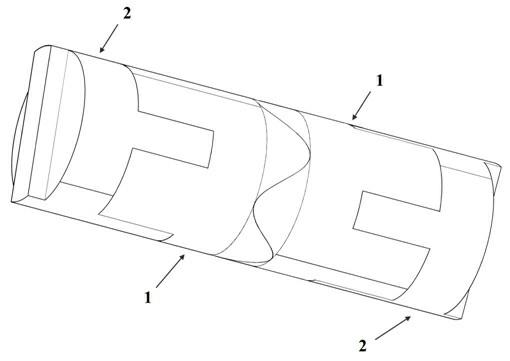

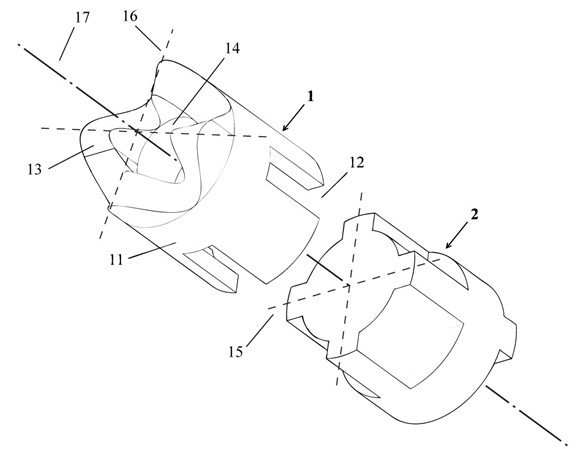

[0019] Such as figure 1 As shown, a connection fitting includes a cylindrical main body 11, a through hole 14 located at the central axis 17 of the main body 11, a groove 12 at one end of the main body, and a wavy curved surface 13 at the other end of the main body. One end of the main body 11 is distributed in a cross shape, and the wavy curved surface 13 is a curved surface generated by a periodically changing smooth curve, and has a plurality of crests and troughs evenly distributed; in this embodiment, a curved surface generated by a sinusoidal curve has a uniform Take the four peaks and troughs of the distribution as an example.

[0020] The ratio of the wave height to the wavelength within a sine cycle of the wavy surface 13 is 0.1 to 2.0; a groove cross reference line 15 corresponding to the cross-shaped groove 12 and a cross line 16 at the highest points of fou

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap