Baffle roller anti-swing mechanism for bucket elevator

A bucket elevator and hoist technology, which is applied in the direction of rollers, conveyor objects, transportation and packaging, etc., can solve problems such as excessive operation swing, increase wear resistance, prolong equipment life, and reduce power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

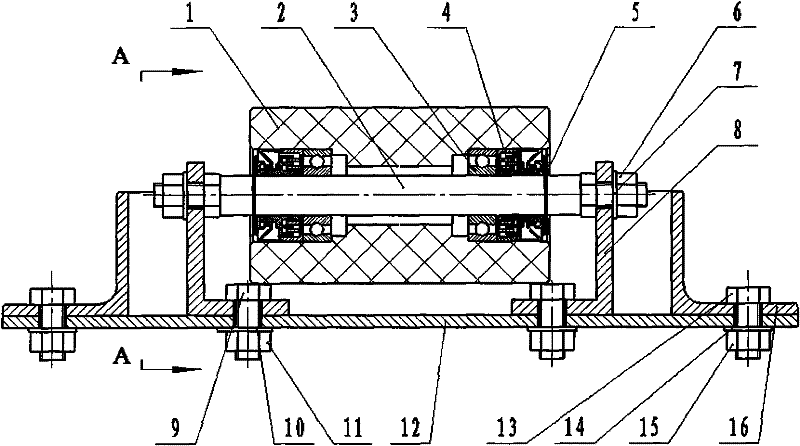

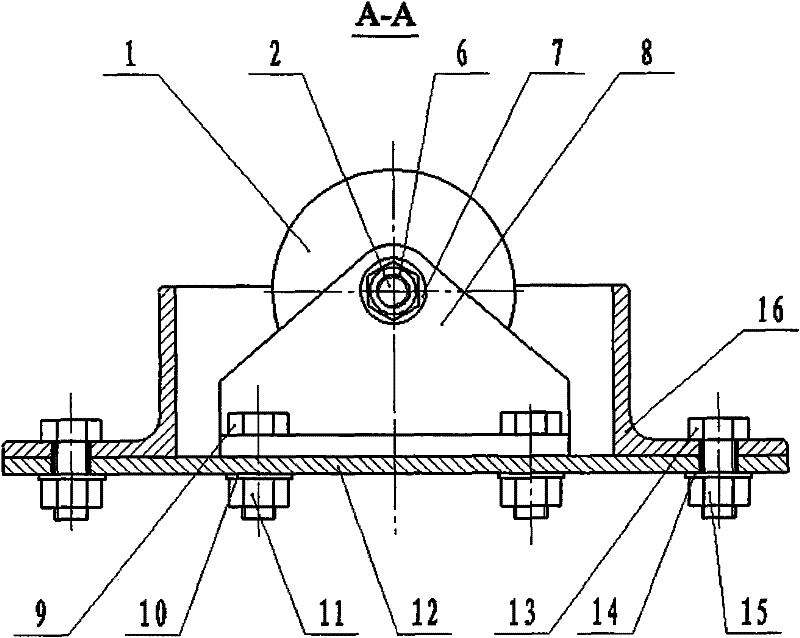

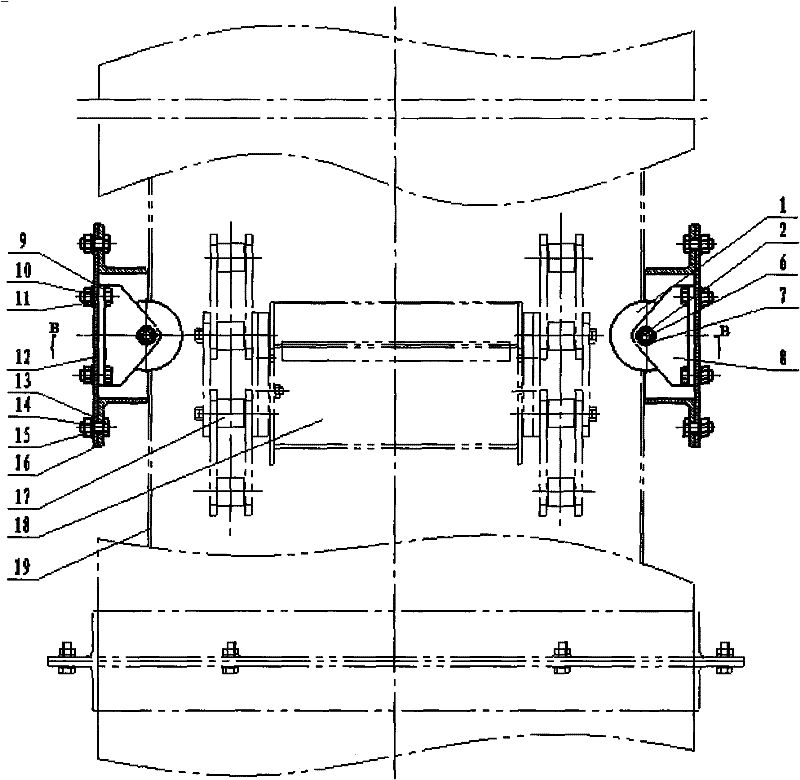

[0020] A guide roller anti-swing mechanism of a bucket elevator, its specific structure is as follows figure 1 As shown, it is mainly composed of a guide roller 1, a support shaft 2, a roller bearing 3, a labyrinth seal assembly 4, an elastic retaining ring 5 for the shaft, a pair of fixing nuts 6, a flat pad 7 and a roller bracket 8. The guide roller 1 is mounted on the support shaft 2 through the support of two inner roller bearings 3 , and the guide roller 1 can freely rotate around the support shaft 2 . In order to prevent dirt from entering the gear roller bearing 3, a rolling bearing with a dust cover is selected for use. Simultaneously, a labyrinth seal assembly 4 is installed outside the gear roller bearing 3 on each side to provide double protection, so that dirt is difficult to invade into the gear roller bearing 3 and the working life can be improved. The two ends of the support shaft 2 are respectively equipped with shaft elastic retaining rings 5 to ensure that th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap