Indoor 3D (3-dimensional) dimension measurement method

A technology of three-dimensional dimensions and measurement methods, applied in the direction of measuring devices, instruments, optical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

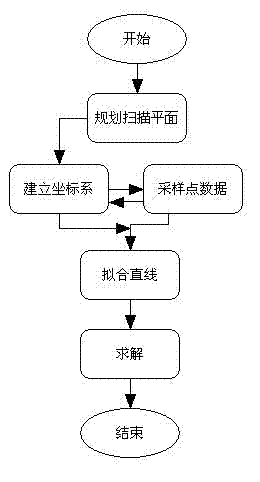

[0041] Example one: See figure 1 , This indoor three-dimensional size measurement method is characterized in that the operation steps are:

[0042] 1) Plan the scanning plane: plan the scanning plane required for the indoor three-dimensional size according to the demand;

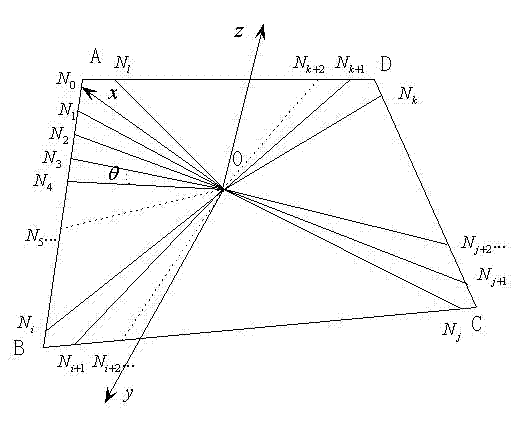

[0043] 2) Establish a coordinate system: construct a coordinate system based on the first point vector and rotation direction vector of the scanning plane;

[0044] 3) Sampling: Obtain the angle and distance values according to the scanning plan, and obtain the coordinates of the sampling point after converting to the constructed coordinate system;

[0045] 4) Fitting: real-time straight line fitting based on least squares method for sampling points, real-time wall quality judgment by fitting straight line, and multiple fitting straight line equations for the sides of the plane can be obtained at the same time;

[0046] 5) Solution: According to the coordinate relationship between the fitted multiple straight line equ

Example Embodiment

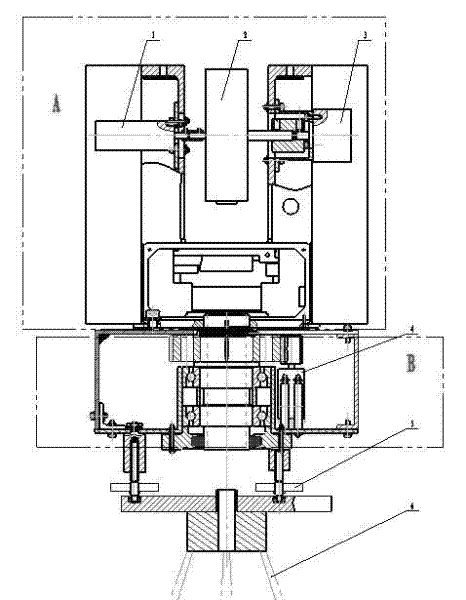

[0047] Embodiment two: This embodiment is basically the same as the first embodiment, and the specific operations of each step are as follows: figure 2 Introduce the basic structure of the scanning device shown in this example. The part that controls the movement is basically divided into two parts, A and B, as shown in the figure. Part B drives part A as a whole to be able to rotate horizontally. In part A, 1 is a DC motor, 2 is a laser sensor, and 3 is a photoelectric encoder, which can obtain the rotation angle. 1 DC motor can drive 2 laser sensor to do vertical movement, photoelectric encoder can record the relative angle of movement. 4 is a stepping motor controlling part A to move at a certain angle, 5 is the leveling structure of the entire device, and 6 is a height-adjustable support structure, usually a tripod.

[0048] First as attached figure 1 Shown is the flow chart of work realization, in which the planned scanning plane is as attached figure 2 The device show

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap