A kind of operation method of robot flexible welding

An operation method and robot technology, which is applied in the fields of automatic welding robot welding, automatic unloading, and automatic stacking, can solve problems such as manual operation, and achieve the effect of improving work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

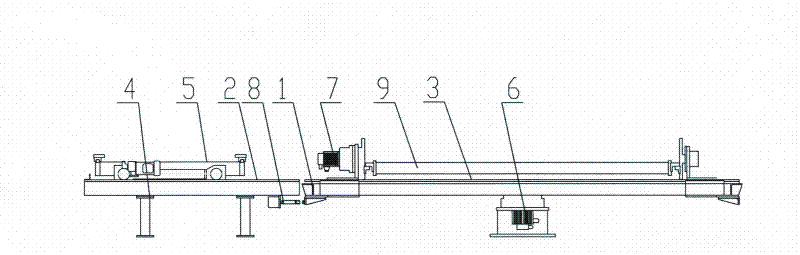

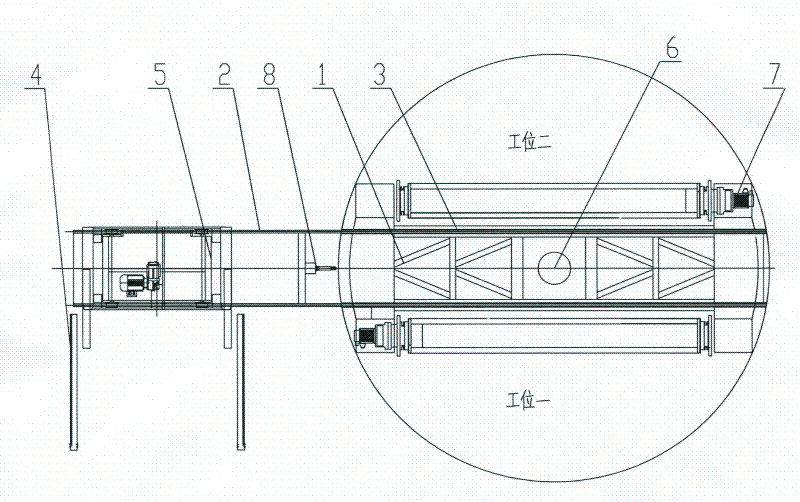

[0021] Such as figure 1 , 2 , 3 shows an operating method of robot flexible welding, its steps:

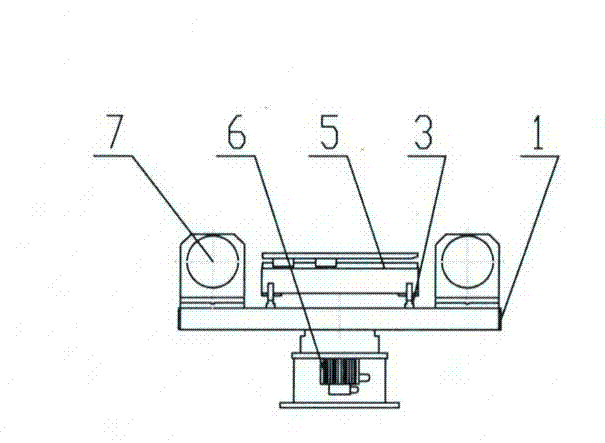

[0022] (1) Transport the raw materials to the loading area (station 1); manually assist the loading and positioning of the raw materials on the quick change tool 9;

[0023] (2) The positioner rotates the clamped workpiece around the rotary axis 6 to the welding area (station 2); robot welding;

[0024] (3) After the welding is completed, the positioner rotates the welded workpiece to the clamping area (station 1);

[0025] (4) The fixed guide rail 3 and the connecting guide rail 2 are connected by a pneumatic positioning pin 8. The intelligent carrier 5 on the fixed guide rail 3 takes out the workpiece on the displacement frame 1 through the connecting guide rail 2 and transports it to the stacking rack 4. So as to automatically complete the handling and coding of workpieces;

[0026] (5) The pneumatic positioning pin 8 disengages the fixed guide rail 3 from the connecting guide rail 2, and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap