fire extinguishing device

A technology of fire extinguishing device and buffer cavity, which is applied in fire rescue and other fields, can solve the problem that the fire extinguishing device has only a small recoil and no recoil, and achieves the effect of improving the safety of use and improving the fire extinguishing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

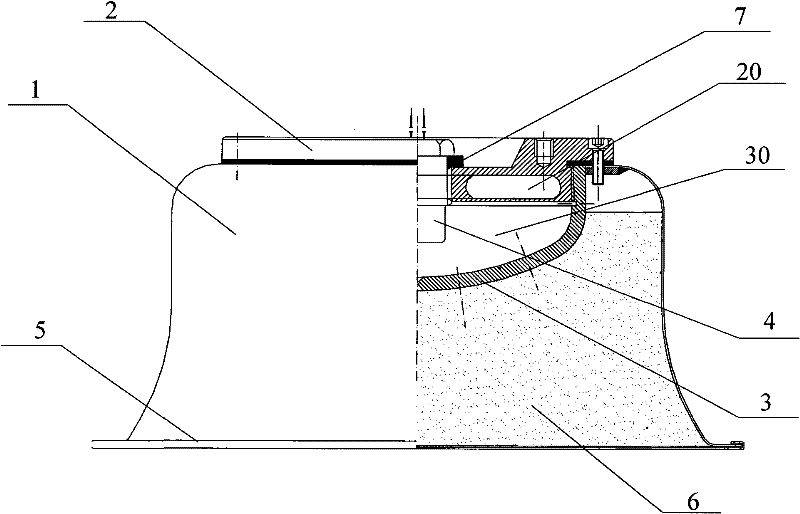

[0022] The technical solutions of the present invention will be further described in detail below through the accompanying drawings and embodiments.

[0023] In order to reduce the recoil generated by the action of the fire extinguishing device, the present invention is realized by improving the gas generator.

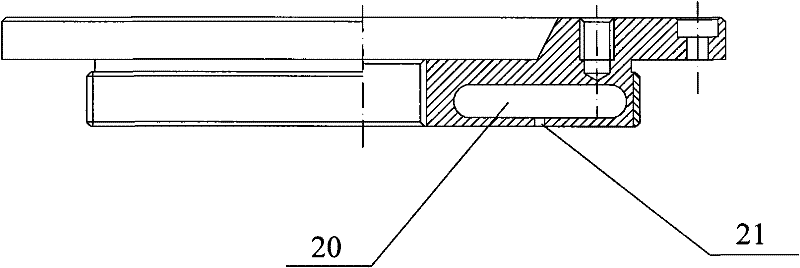

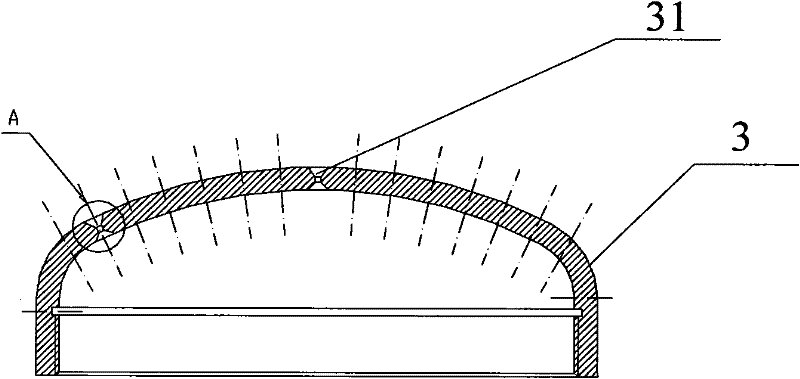

[0024] figure 1 It is a schematic diagram of the structure of the fire extinguishing device of the present invention. As shown in the figure, the fire extinguishing device of the present invention specifically includes: a casing 1, a top cover 2 and a porous member 3. The top cover 2 is fixed on the top of the casing 1, and the top cover 2 has Buffer chamber 20; The porous member 3 is fixed on the top cover 2 and is accommodated in the housing 1, and the combustion chamber 30 formed by the porous member 3 and the top cover 2 is in communication with the buffer chamber 20.

[0025] The present invention optimizes the structure of the top cover, and sets a buffer cavity in the top

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap