Caliper ruler

A caliper, integrated technology, applied in the direction of mechanical diameter measurement, can solve the problems of concave and convex, inability to take out, difficult to measure the inner diameter of cylindrical castings, etc., to achieve the effect of small error and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

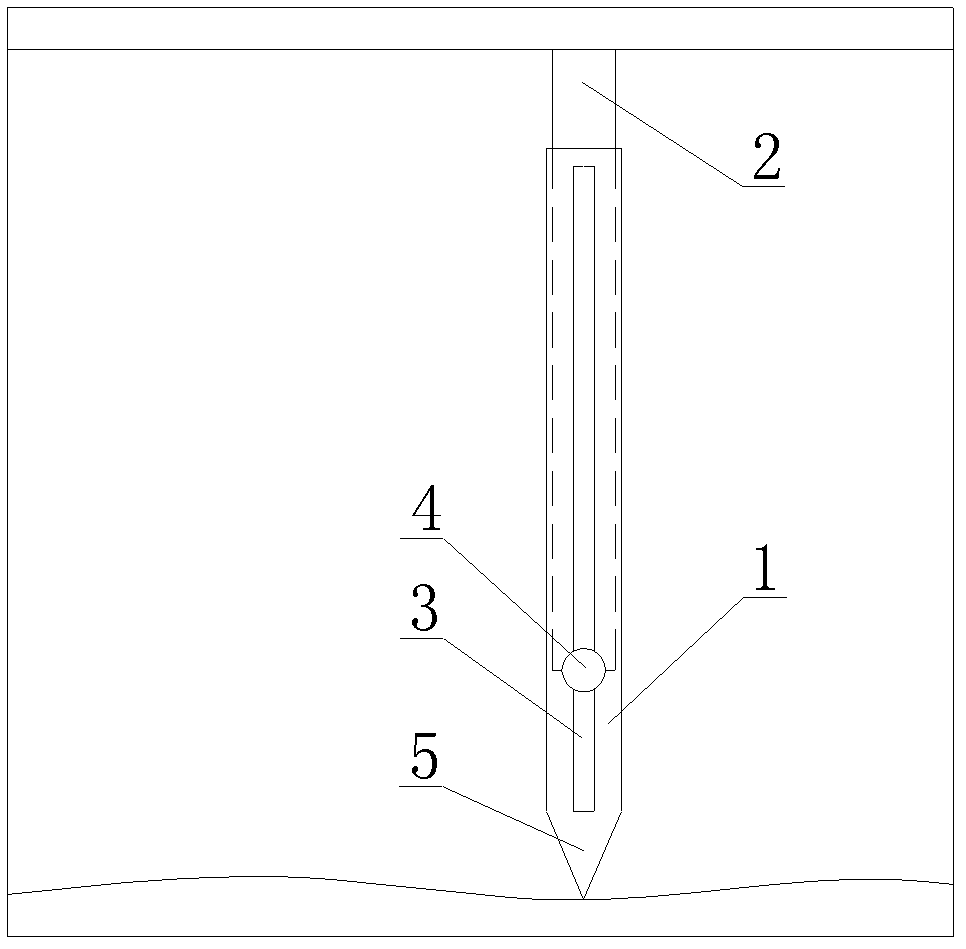

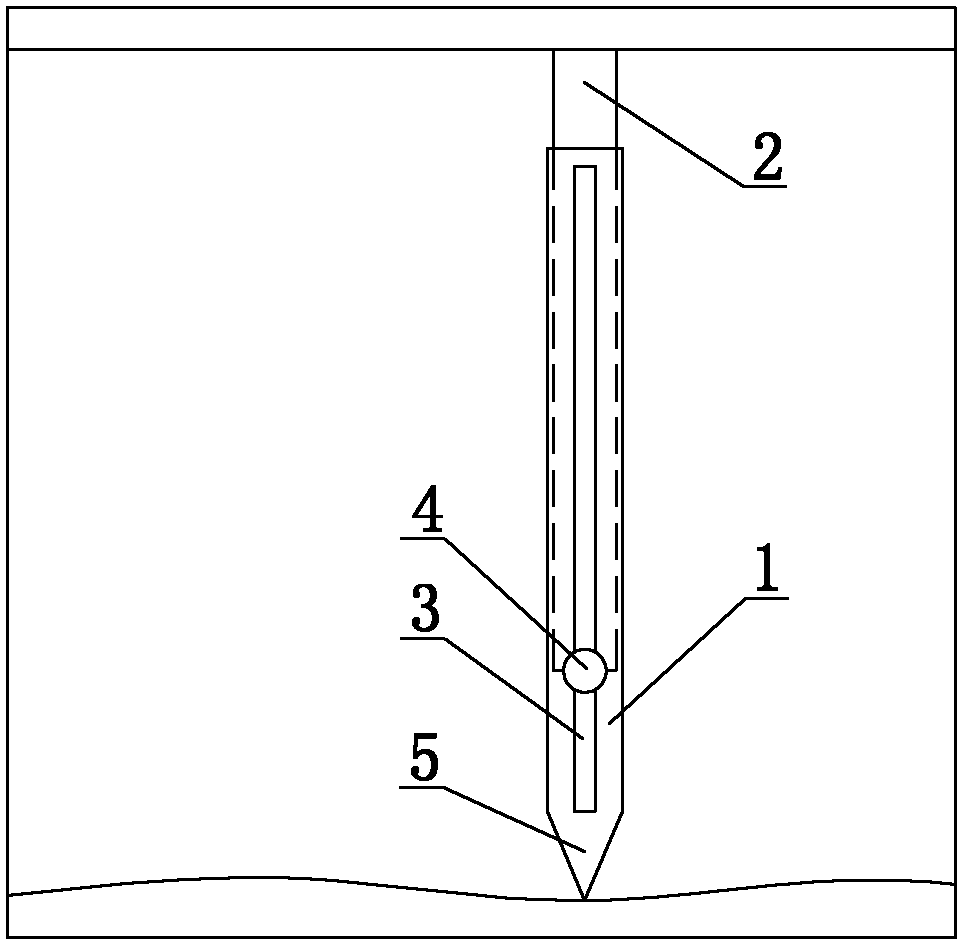

[0012] Such as figure 2 As shown, a caliper includes a caliper main body 1, a sliding scale 2 is provided in the caliper main body 1, a chute 3 is provided on the caliper main body 1, and a scale is slidably connected in the chute 3 2 Tighten the bolts 4 connected. The scale mark on the top of the scale 2 is the height of the caliper main body 1 . The lower part of the caliper body 1 is provided with a measuring tip 5 . The caliper main body 1 and the measuring tip 5 are integrally structured. The height of the caliper main body 1 is 200mm, so the scale marks on the top of the scale 2 should be 200mm. When in use, the caliper is placed in a cylindrical casting, the sliding scale 2 is released, and the measuring tip 5 at the lower end of the caliper main body 1 is against it. The lower part of the cylindrical casting is depressed, and the upper end of the scale 2 is against the upper side wall of the cylindrical casting. The inner diameter of the cylindrical casting can be ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap