Transition base for processing inclined holes in inner cylinder space of gas turbine compressor exhaust cylinder

A transition seat and compressor technology, which is applied to metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problem that the oblique hole in the exhaust cylinder of the gas turbine compressor cannot meet the design requirements, and achieves simple structure, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

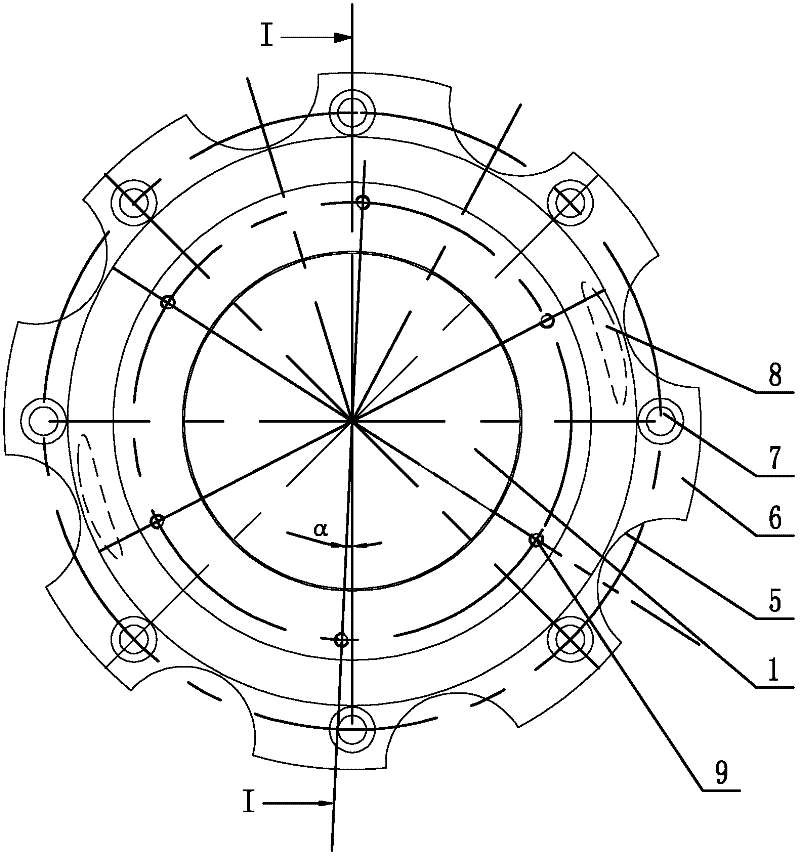

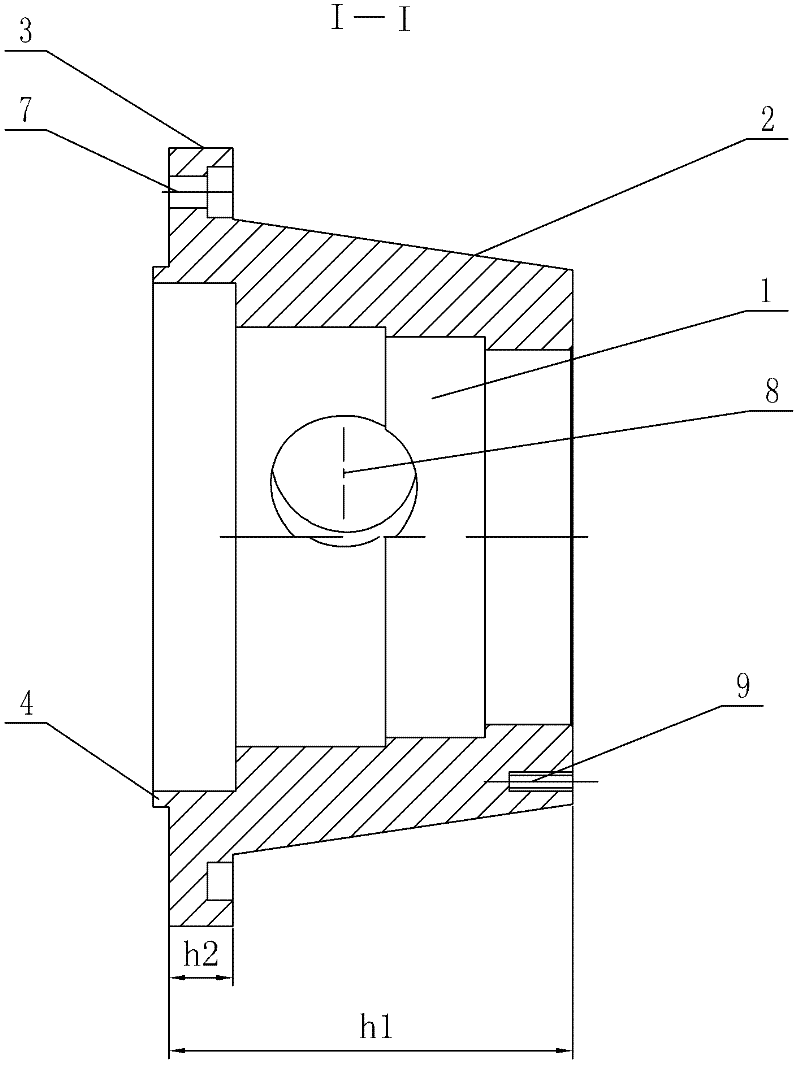

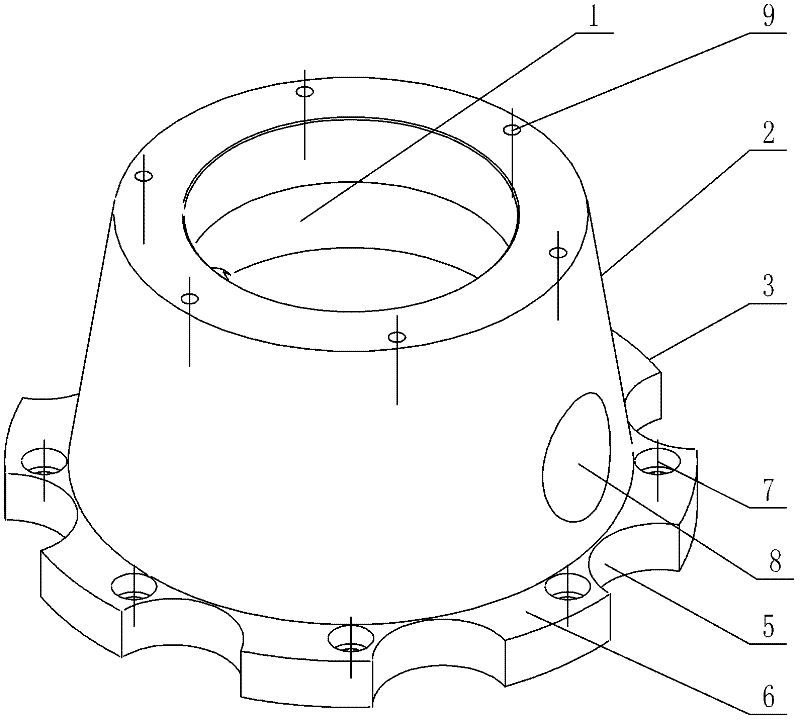

[0007] Specific implementation mode one: combine Figure 1 ~ Figure 3 Explain that the transition seat used for processing the oblique hole in the cylinder space of the exhaust cylinder of the gas turbine compressor in this embodiment, the transition seat is provided with a through inner cavity 1 along the axial direction, which is used to connect the power transmission connected with the large right-angle milling head device, the shape of the transition seat is composed of a conical body 2 and a cylinder 3, the large-diameter end face of the conical body 2 is integrated with one end face of the cylinder 3, and the other end face of the cylinder 3 is provided with a ring Shaped protrusion 4, used for connection and positioning with the concave groove of the large right-angle milling head, the conical frustum 2 and the cylinder 3 are coaxially arranged, the outer diameter of the large-diameter end surface of the conical frustum 2 is smaller than the outer diameter of the cylinder 3

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 2 Note that the overall height h1 of the transition seat in this embodiment = 132 mm, and the height h2 of the cylinder 3 = 20 mm. Others are the same as in the first embodiment.

[0009] How to use the transition seat: before processing, first connect the large right-angle milling head with the main shaft, connect the power transmission device to the large right-angle milling head, position the transition seat and the large right-angle milling head through the seam and connect them with screws, and connect the small right-angle milling head The milling head is connected with the small-diameter end face of the circular platform body of the transition seat, and after fine-tuning the angle, tighten the screws to process. Its main function is to change the positioning direction of the small right-angle milling head during processing and protect the power transmission device.

[0010] Since the tool is in a spatial positi

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap