Rotary net cage

A rotary and net cage technology, which is applied in fish farming, application, climate change adaptation, etc., can solve problems such as not being able to better meet production needs, and achieve the effects of novel structure, easy fishing, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

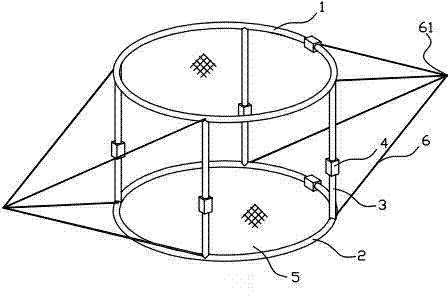

[0016] Example 1: Reference figure 1 , image 3 , Rotary cage, including a cage with a certain breeding space surrounded by a net 5 supported by a rigid bracket, wherein: the rigid bracket is connected by a hollow tube; the rigid bracket is divided into unconnected upper Bracket 1 and lower bracket 2. The multifunctional part 4 can inflate or discharge the upper support 1 and the lower support 2 as required. By changing the weight of each part of the rigid support, the entire rotary net cage can be rotated on demand, so that each surface can be controlled to rise. To the water surface, it is easy to clean, greatly increase the dissolved oxygen in the water body, and reduce the impact of fouling organisms on the environment in the cage. The multifunctional part 4 can also increase the aeration volume to make the rotary net cage part float above the water surface, which is convenient for catching.

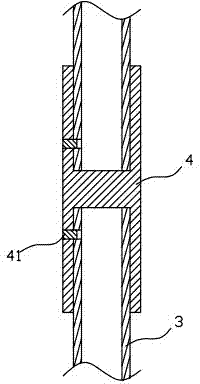

[0017] The multifunctional part 4 is a sleeve structure, and the middle part of the

Example Embodiment

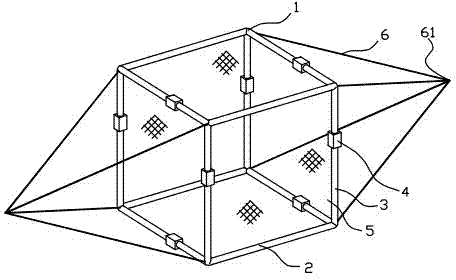

[0021] Example 2: Reference figure 2 , image 3 , Rotary cage, including a cage with a certain breeding space surrounded by a net 5 supported by a rigid bracket, wherein: the rigid bracket is connected by a hollow tube; the rigid bracket is divided into unconnected upper Bracket 1 and lower bracket 2. The multifunctional part 4 can inflate or discharge the upper support 1 and the lower support 2 as required. By changing the weight of each part of the rigid support, the entire rotary net cage can be rotated on demand, so that each surface can be controlled to rise. To the water surface, it is easy to clean, greatly increase the dissolved oxygen in the water body, and reduce the impact of fouling organisms on the environment in the cage. The multifunctional part 4 can also increase the aeration volume to make the rotary net cage part float above the water surface, which is convenient for catching.

[0022] The multifunctional part 4 is a sleeve structure, and the middle part of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap