No-missing chain-driven rotary cultivator with functions of soil casting, stubble cleaning and subsoiling

A chain drive and rotary tiller technology, applied in the field of rotary tillers, can solve the problems of inability to achieve rotary tillage, subsoiling, stubble removal, etc. with one machine for multi-purpose, high power consumption, inability to solve, etc., and achieves improved rotary tillage and stubble removal effect, Save maintenance costs and produce easy results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

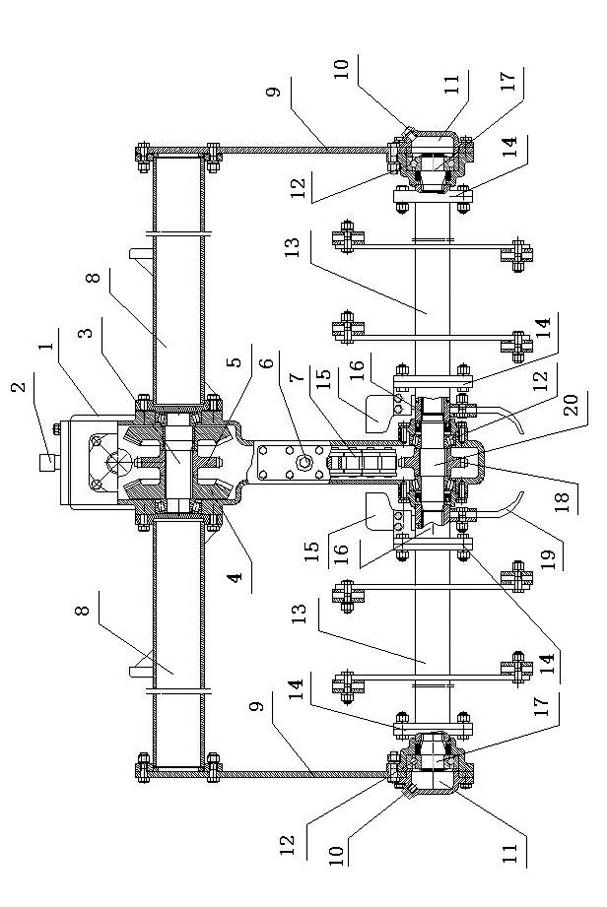

[0023] Embodiment 1, with reference to Figure 1-3 , a subsoiling rotary tiller without missing tillage and chain transmission, which includes a chain transmission box assembly, and the chain transmission box assembly is arranged in the way of intermediate transmission;

[0024] The chain transmission box assembly includes a transmission box body 1, a power input shaft 2 and a transmission sprocket shaft 3 are arranged inside the upper end of the transmission box body 1, and a meshed power input gear 4 is arranged on the power input shaft 2 and the transmission sprocket shaft 3, The transmission sprocket shaft 3 is also provided with a power input sprocket 5; the lower end of the transmission case 1 is provided with a power output shaft 20, and the power output shaft 20 is arranged on the transmission case 1 through a bearing and a bearing oil seal seat 12, and the power output The shaft 20 is provided with a power output sprocket 18; the power input sprocket 5 and the power outp

Embodiment 2

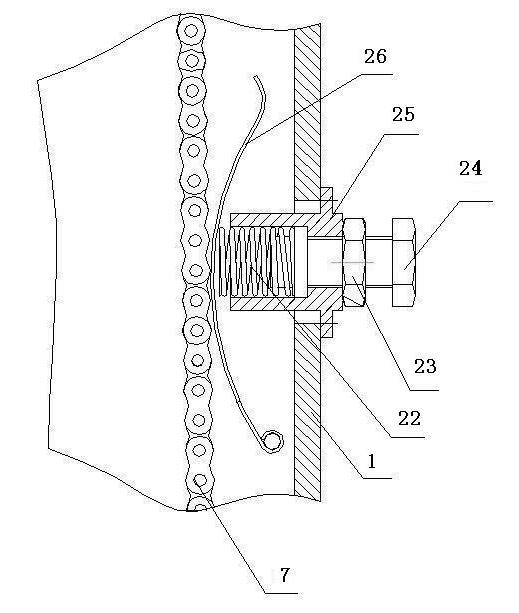

[0026] Embodiment 2, in the subsoiling rotary cultivator described in Embodiment 1 without missing tillage chain transmission, throwing soil and stubble removal: the bearing connected to the support arm 9 and the bearing oil seal seat 12 are provided with a lubricating oil chamber 11, and a lubricating oil chamber 11 is provided in the bearing and the bearing An oil filling port 10 communicating with the lubricating oil chamber 11 is also provided on the oil seal seat 12 .

Embodiment 3

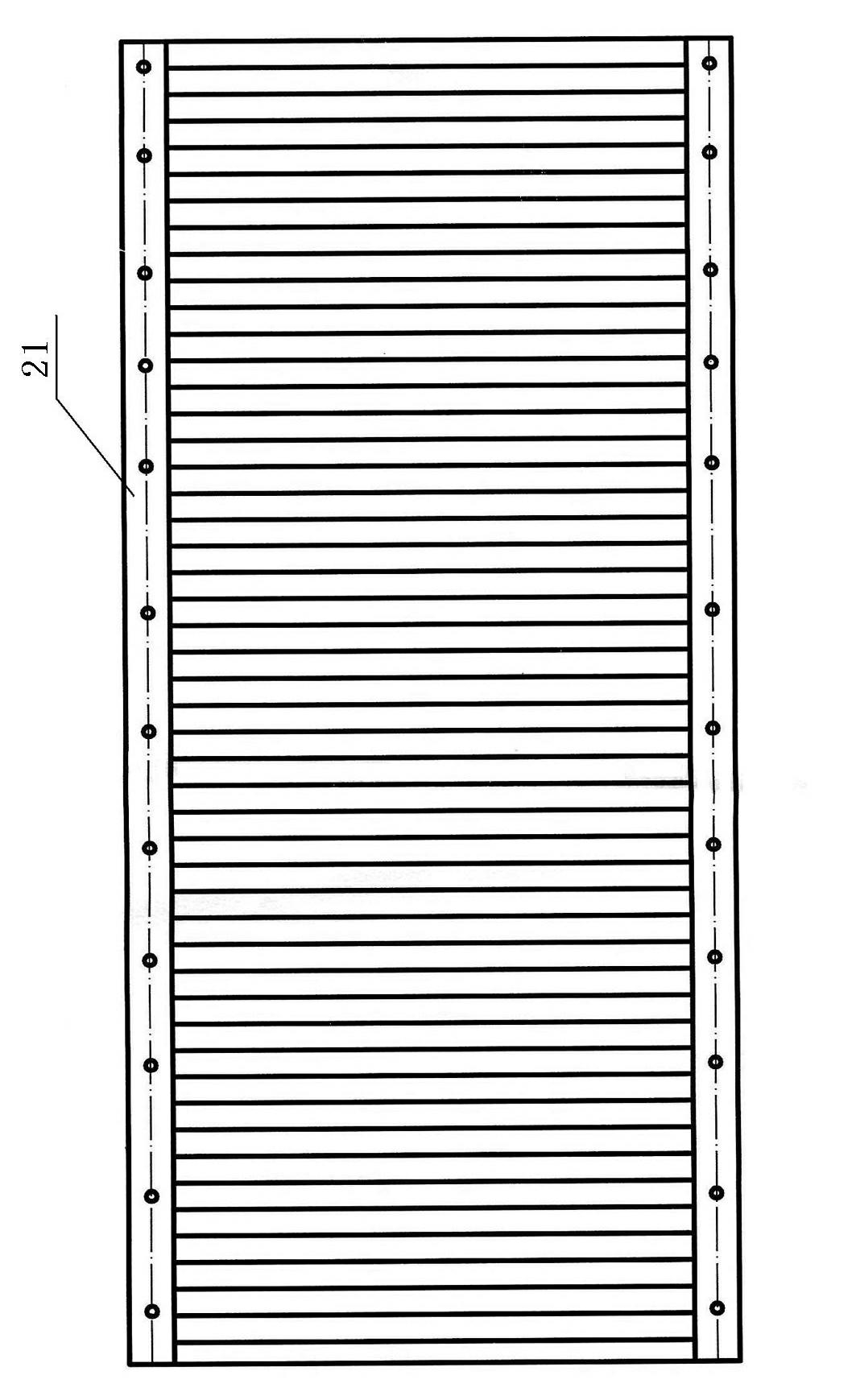

[0027] Embodiment 3, with reference to figure 2 , In the subsoiling rotary tiller without missing tillage chain transmission described in embodiment 1 or 2 or 3: a fence-type cover plate 21 is provided above the subsoiling cutter head shaft assembly 13 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap