Mixing pile blade

A technology of stirring blades and stirring piles, which is applied to sheet pile walls, buildings, infrastructure projects, etc., can solve the problems of difficulty in construction of stirring piles and affect construction quality, and achieve the effect of simple structure and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

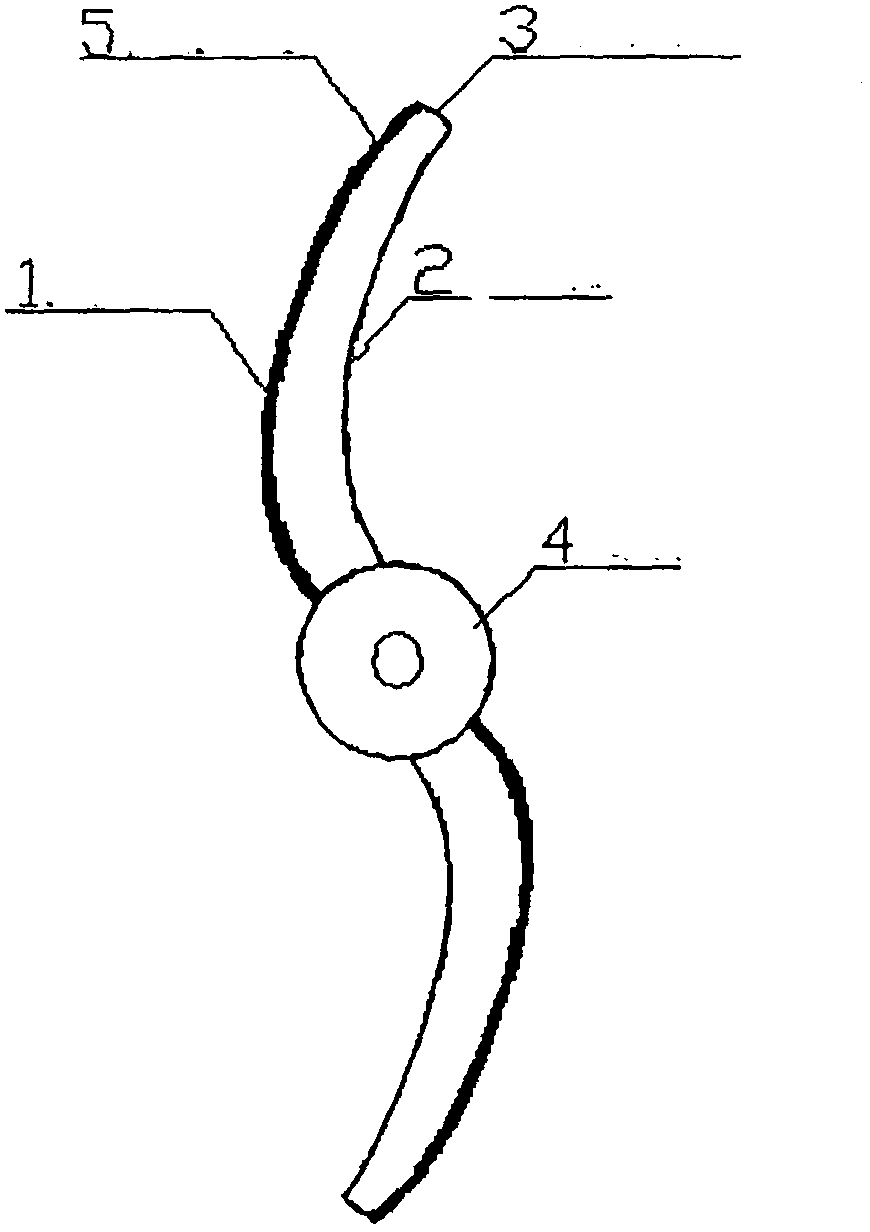

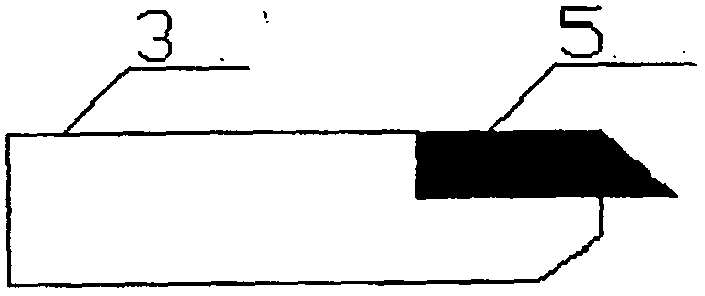

[0012] Such as figure 1 , figure 2 Shown:

[0013] The stirring blade 3 is connected to the drill pipe 4 (drive shaft), and the driving device (omitted, not shown) is connected to the drill pipe 4. The outside of the stirring blade 3 is arc-shaped to form an outer arc surface 1, and the inside is also arc-shaped to form an inner arc surface 2. , the arc of the outer arc surface 1 and the inner arc surface 2 can be the same or can be similar, and the rotation direction of the drill rod 4 is from the inner arc surface 2 to the outer arc surface 1, that is, the outside of the stirring blade 3 (the outer arc surface 1) is the stirring When the blade 3 rotates, it first encounters one side of the soil layer; on the outer arc surface 1 of the stirring blade 3, the cemented carbide 5 is inlaid and welded. The arc shapes on the outside and inside of the stirring blade 3 are set according to technical common sense.

[0014] Description of the application process of the present inventi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap