Wind turbine blade with embedded diversion pipe capable of controlling tip vortex

A technology of wind turbine blades and guide tubes, applied in the field of wind turbine blades, can solve the problems of airfoil self-noise, turbulent inflow noise and the like, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention are described in detail below: the present embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following implementation example.

[0030] This embodiment can be used as an extension to connect with common wind turbine blades through a connecting device, or it can be integrally formed by considering the impact of this embodiment on the aerodynamic structure of the wind turbine blades when designing the wind turbine blades.

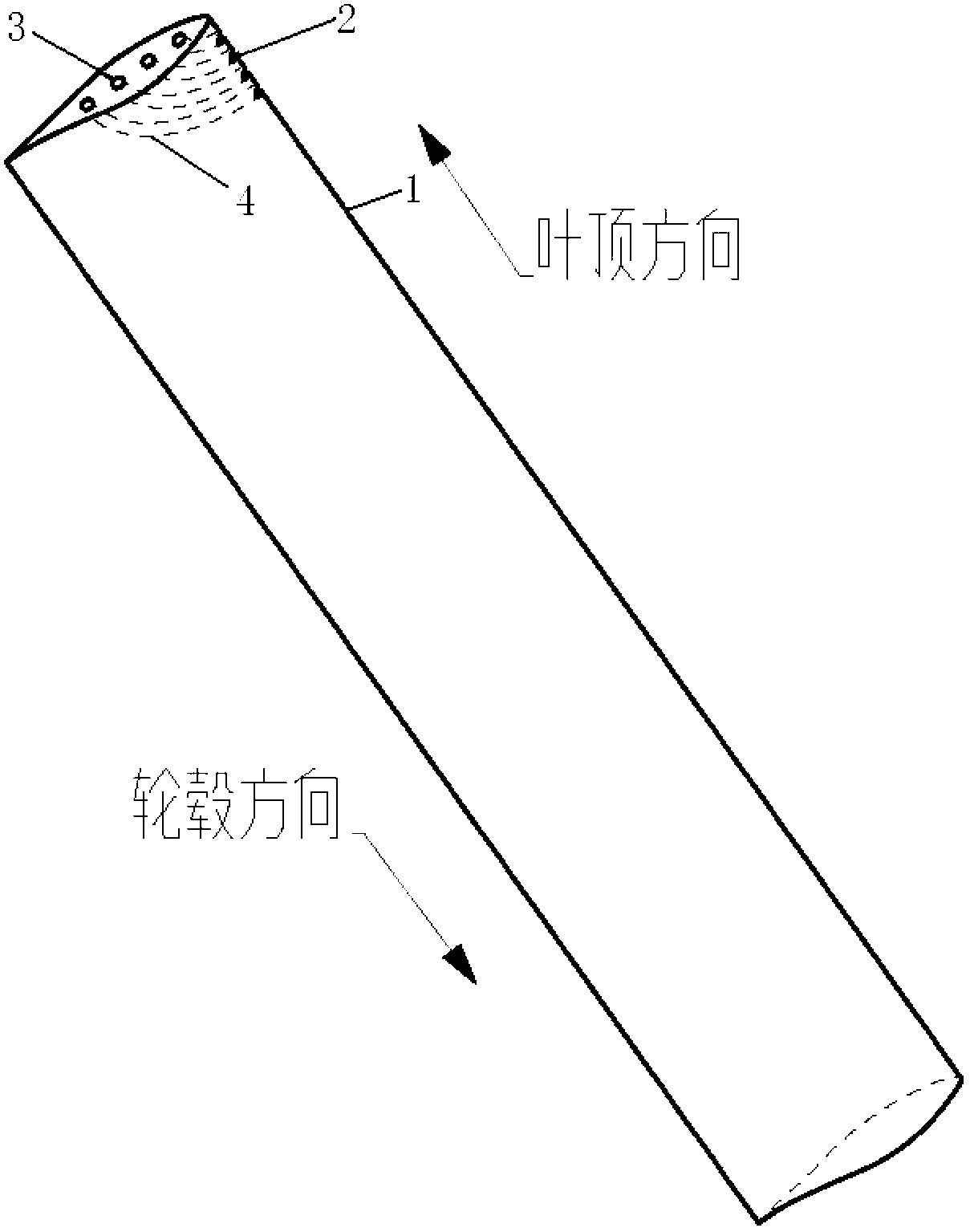

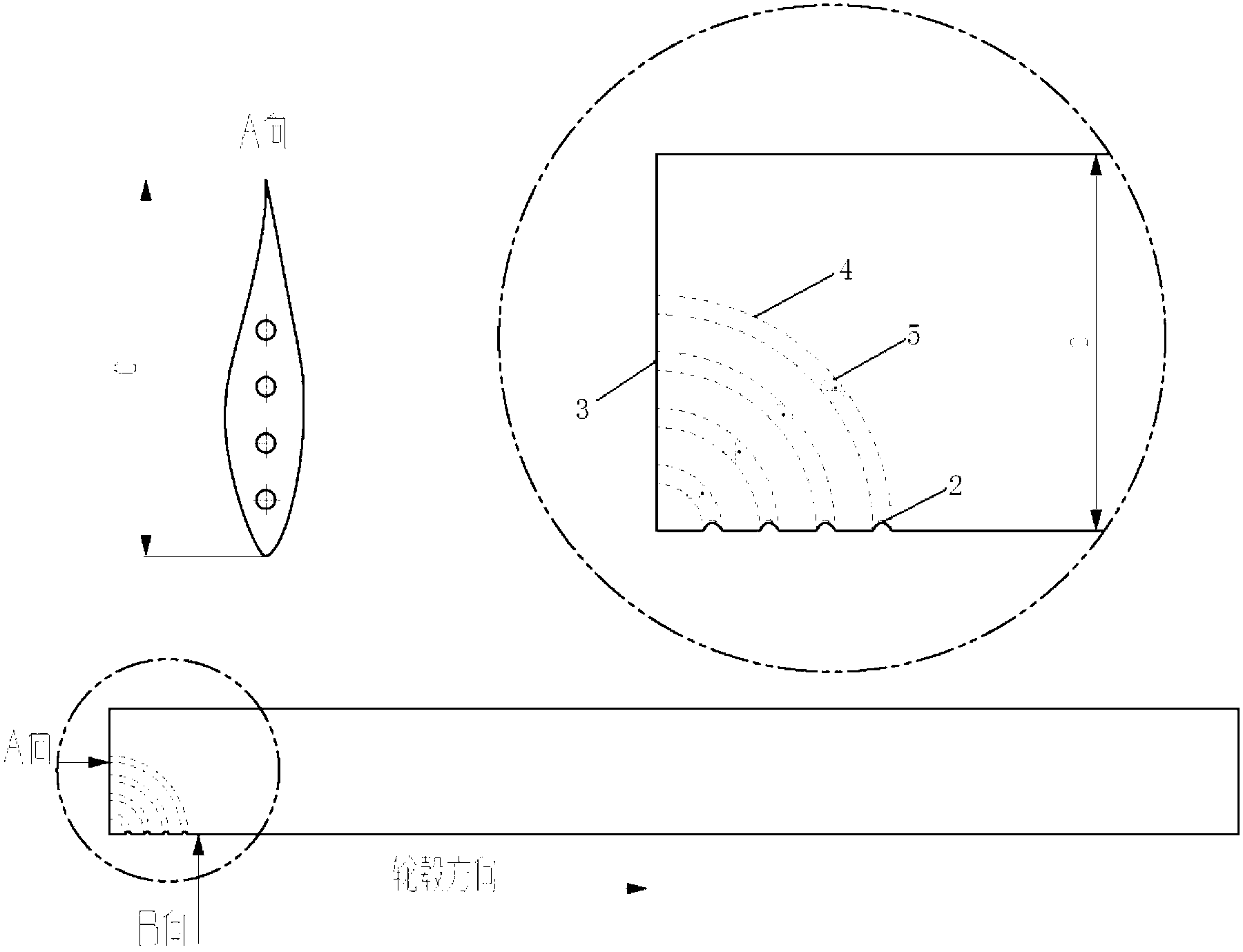

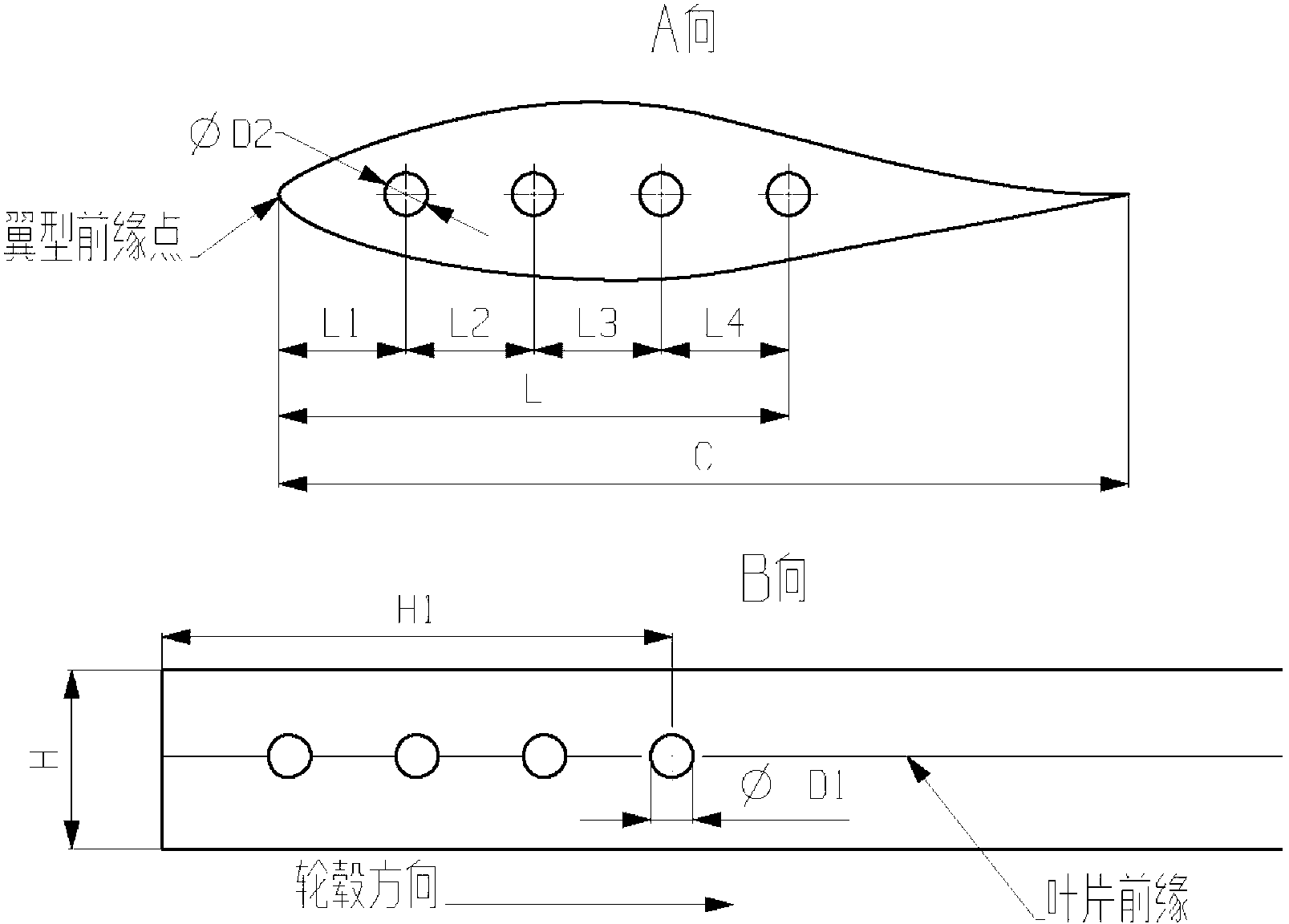

[0031] Such as figure 1 As shown, the present embodiment includes a blade top device 1, an air inlet 2, an air outlet 3 and a guide pipe 4, wherein, there are several air inlets 2, and are arranged in front of the blade top of the blade top device 1. There are several air outlets 3 at the edge of the blade tip device 1, and th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap