Adaptive bag conveying mechanism

A conveying mechanism and self-adaptive technology, applied in the direction of packaging, etc., can solve the problems that the bag strips cannot pass through, the thickness of the bag strips is relatively high, and it is easy to be crushed and squeezed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

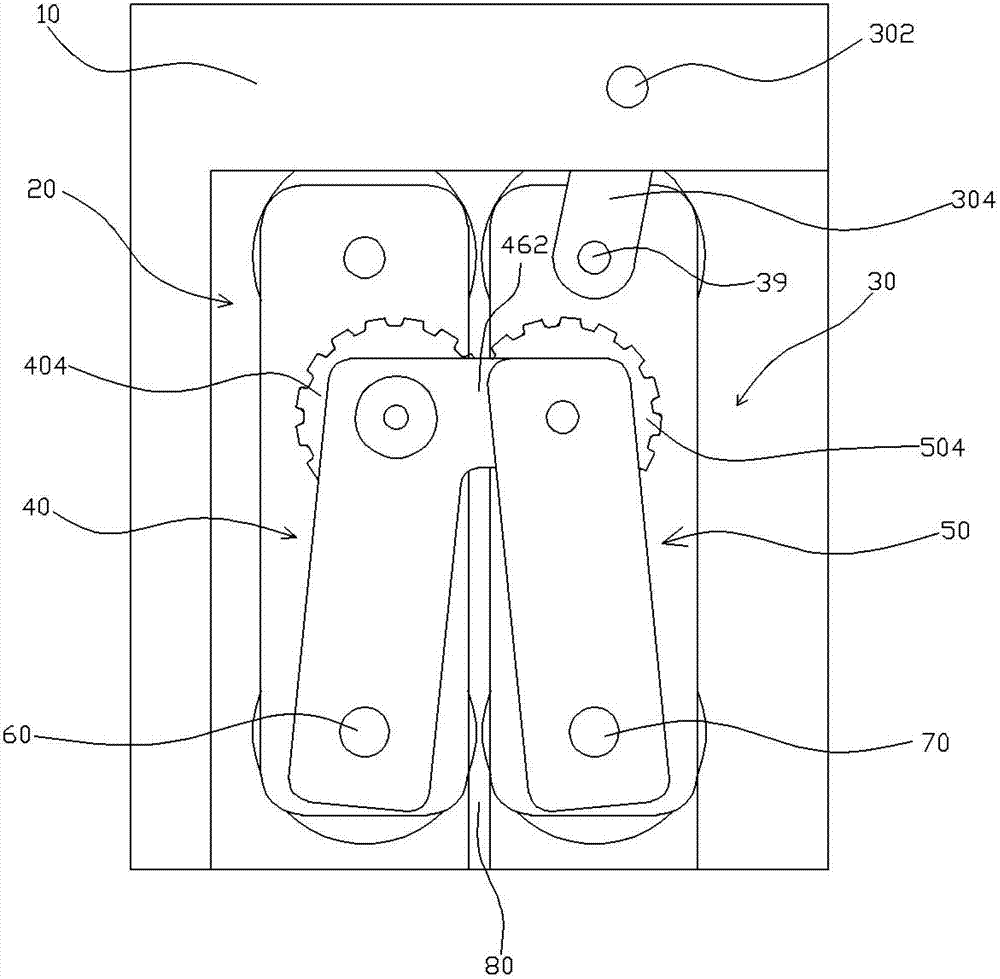

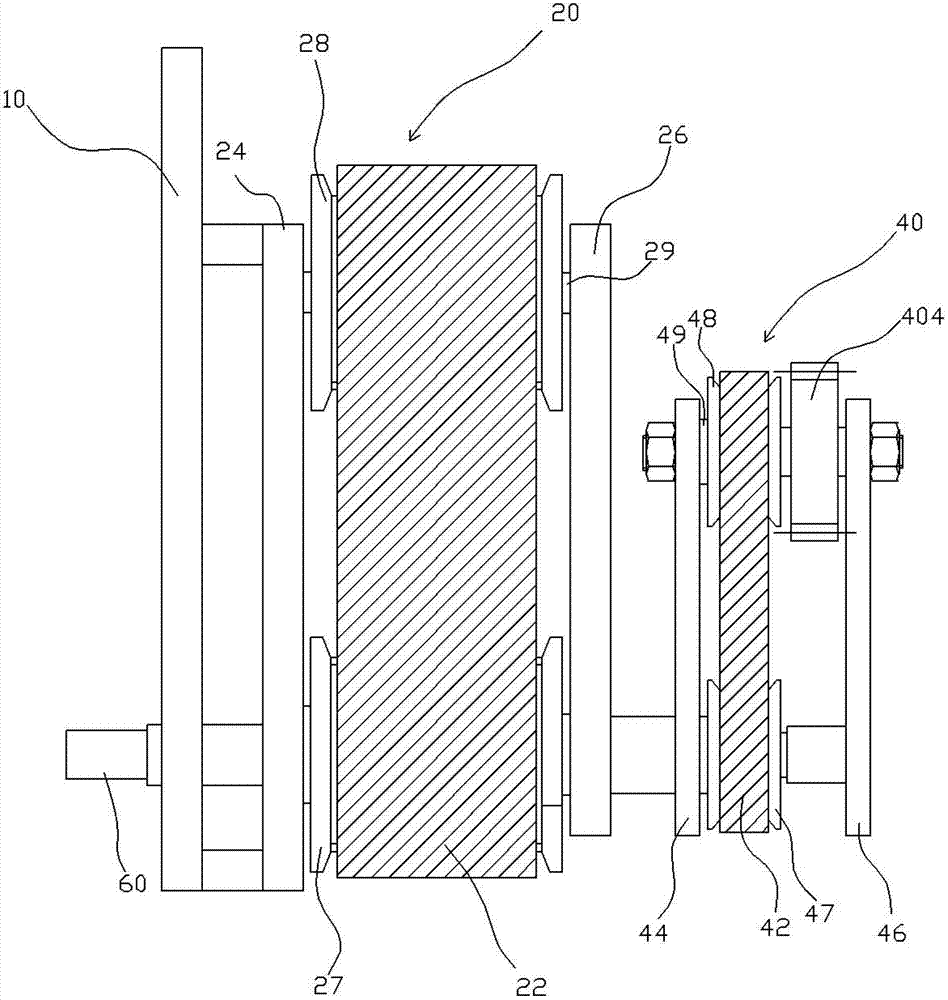

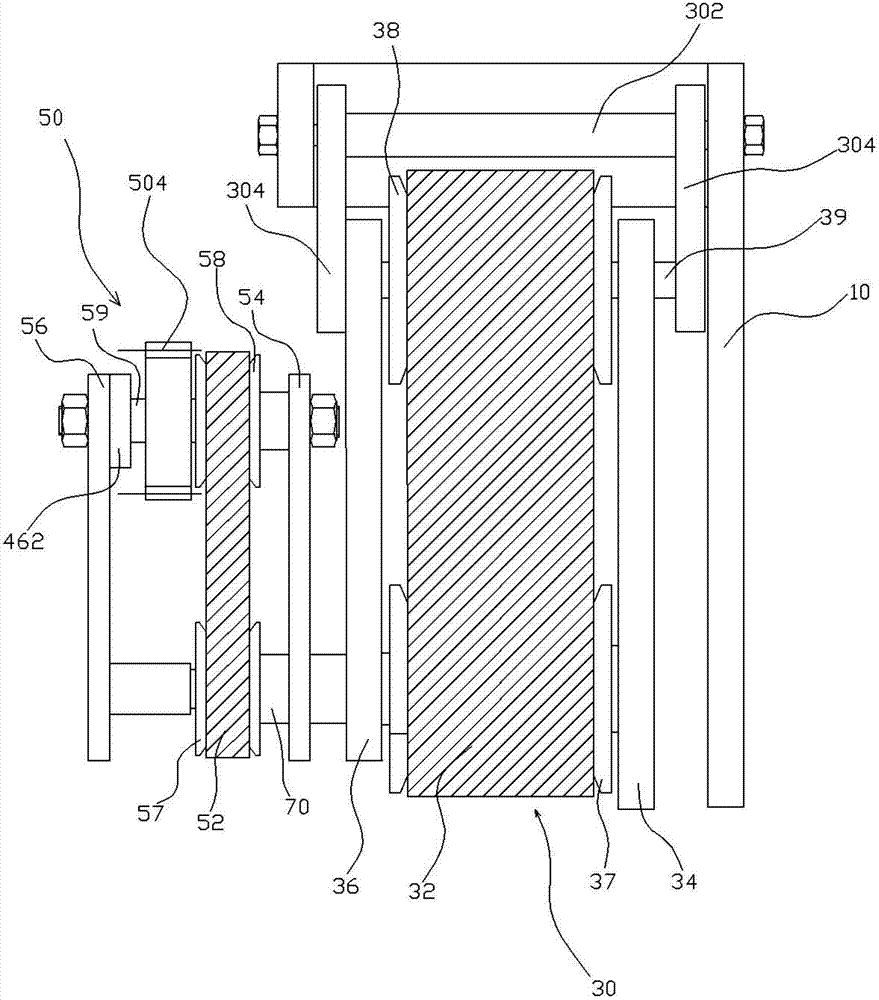

[0022] Figure 1 to Figure 4 Schematically shows an adaptive bag strip conveying mechanism according to an embodiment of the present invention.

[0023] Such as figure 1 As shown, in an embodiment of the present invention, the self-adaptive bag transport mechanism is driven by the frame 10, the main clamping unit 20, the secondary clamping unit 30, the main gear transmission unit 40, the secondary gear transmission unit 50, and a Shaft 60 and a driven shaft 70 form. Wherein, the main clamping unit 20 and the auxiliary clamping unit 30 are arranged side by side on one side of the frame 10, the main gear transmission unit 40 is arranged on one side of the main clamping unit 20, and the secondary gear transmission unit 50 is arranged on the auxiliary clamping unit 30 and arranged side by side with the main gear transmission unit 40 . The lower ends of the main

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap