Coating anticondensation performance test system and test method

A test system and anti-condensation technology, which is applied in measuring devices, material weighing, analyzing materials, etc., can solve the problem of large human operation errors, inability to accurately evaluate the anti-condensation performance of coatings, and inability to accurately, comprehensively and scientifically evaluate Coating anti-condensation performance test device and test method, etc., to meet the test requirements and the test results are intuitive and readable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0061] Example 1: Thin anti-condensation liquid coating

[0062] Weigh a 20g sample of the anti-condensation paint, and apply it to the outer surface of the paint carrier twice according to step 1), and then place it in the laboratory to dry. After drying for 7 days, place the prepared paint carrier with the coating on the surface in the specified position in the temperature and humidity control chamber, and gradually carry out the test according to step 2) to step 6) in the test method, and calculate according to step 7).

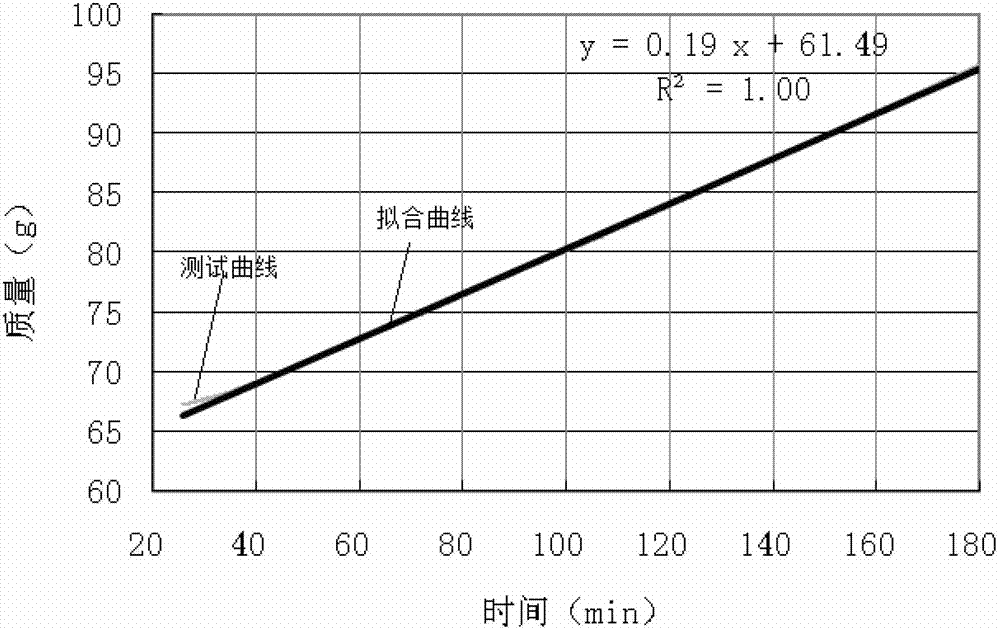

[0063] Test conditions of temperature and humidity control chamber: temperature is 30℃, relative humidity is 70%. The working temperature of the circulating water bath is 10°C. The temperature difference between the inside and outside of the coating applied to the surface of the paint carrier is 20°C. The anti-condensation performance test process curve of the coating is as follows image 3 As shown, the abscissa in the figure is time (min), this test cycle is 3

Example Embodiment

[0069] Example 2: Thick anti-condensation powder coating

[0070] Carry out the test operation according to the aforementioned test methods and steps, the specific operating values are:

[0071] Weigh 70g sample of anti-condensation paint, follow step 1) to stir and disperse evenly with water, and then evenly paint on the outer surface of the paint carrier in two passes, and then dry for 7 days, then cover the prepared paint carrier with the coating on the surface For the specified position in the temperature and humidity control chamber, gradually follow the steps 2) to 6) of the test method for testing, and calculate according to step 7).

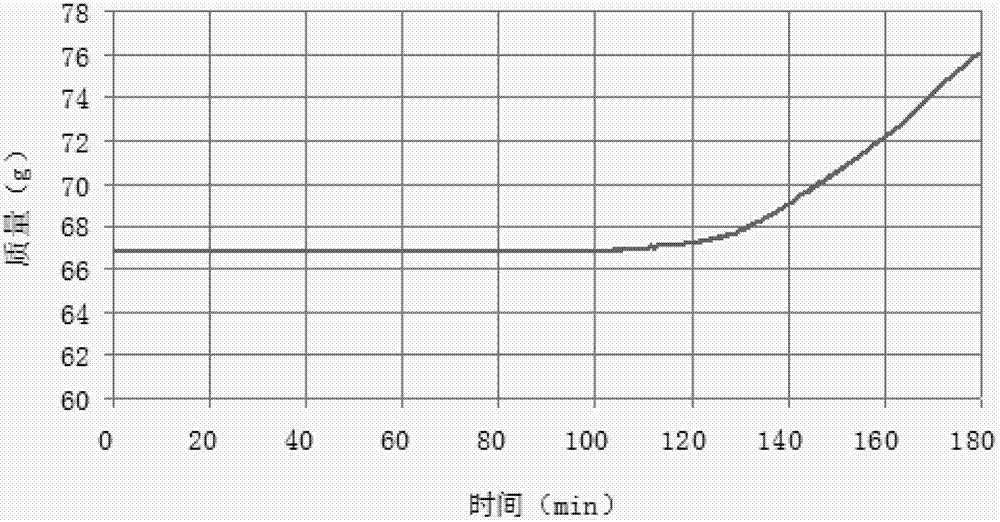

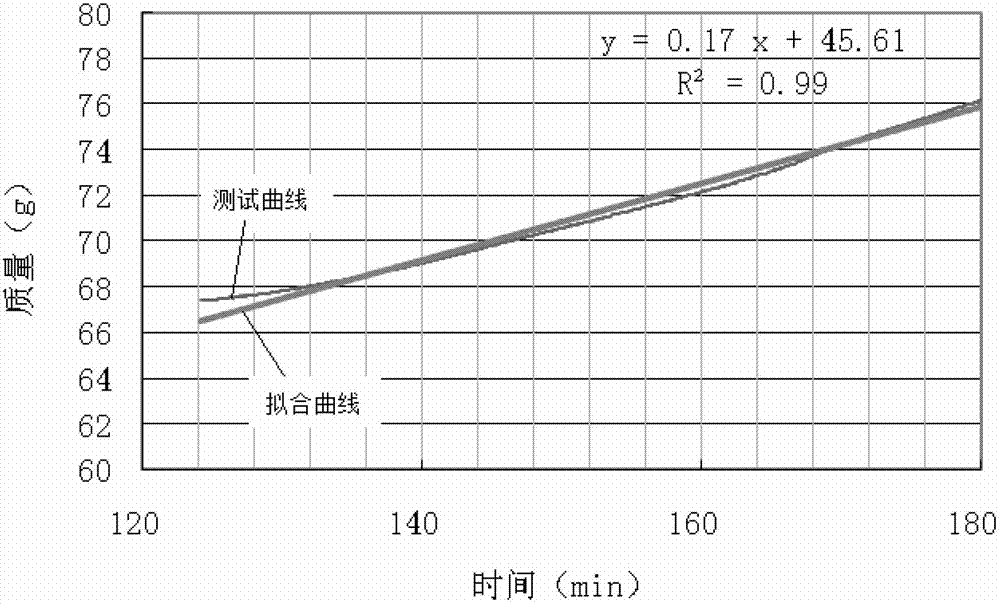

[0072] Test conditions of temperature and humidity control chamber: temperature is 25℃, relative humidity is 95%. The circulating water bath temperature is 3°C. The temperature difference between the inside and outside of the coating applied to the surface of the paint carrier is 22°C. The anti-condensation performance test process curve of th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap