High-efficiency mechanical combined bundling press

A mechanical and combined technology, applied in packaging, tobacco, food science, etc., can solve problems such as low work efficiency, short service life, damage, etc., and achieve the effect of convenient operation and maintenance, high work efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

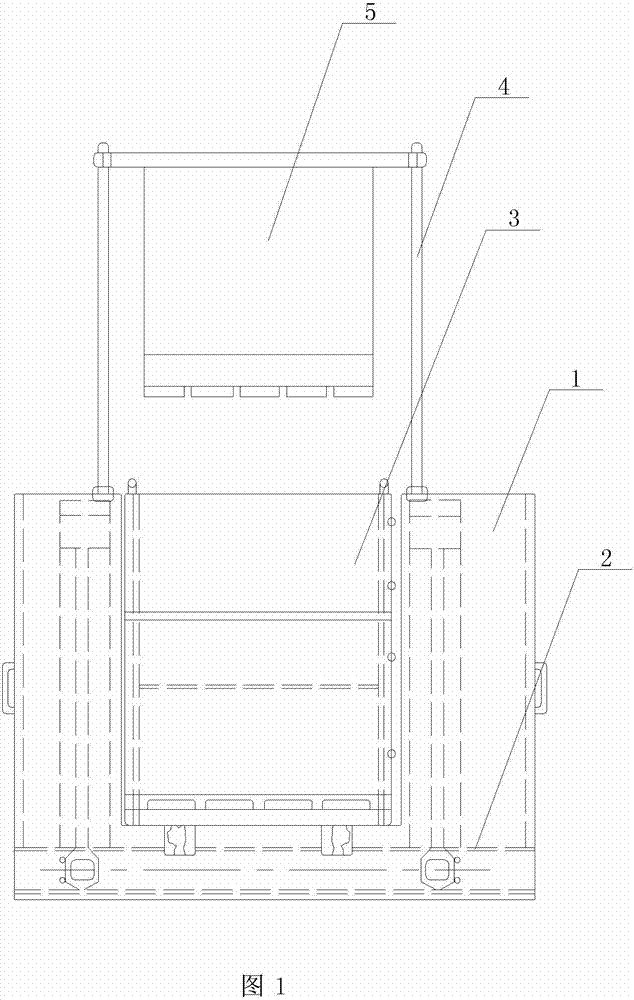

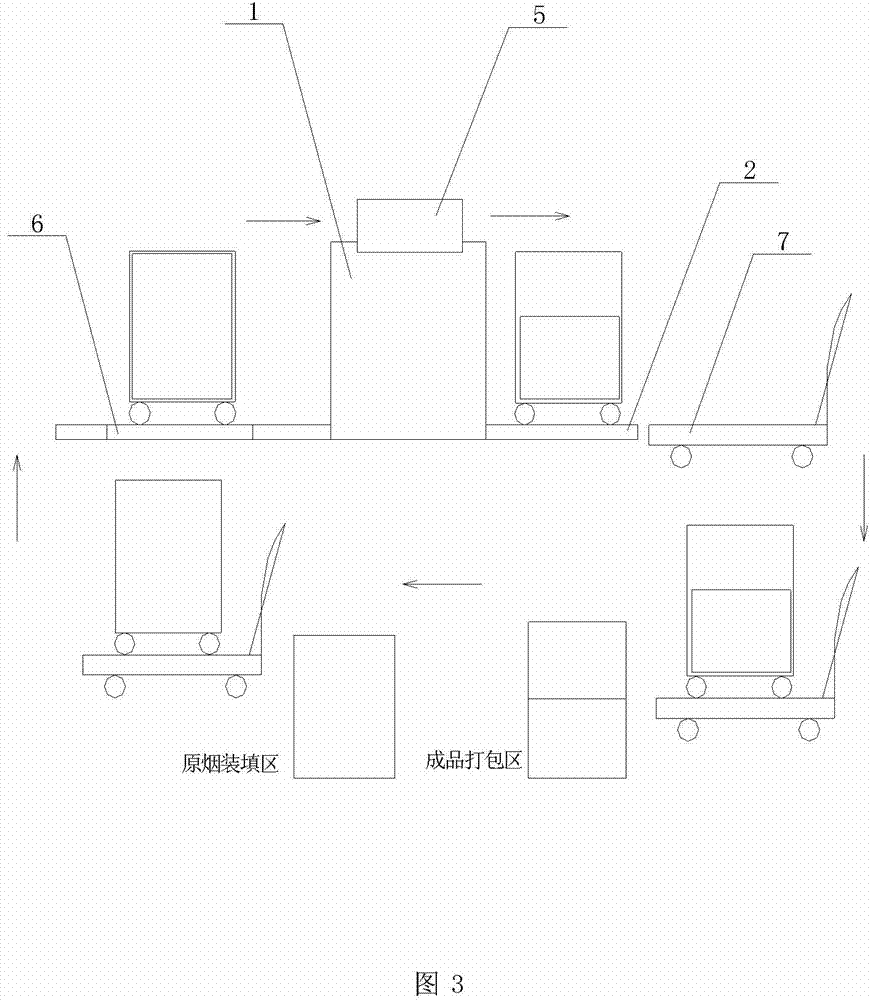

[0012] Reference Figure 1-Figure 3 This specific implementation adopts the following technical solutions: it is composed of a box body 1, a guide rail 2, a quick-change box 3, a brace 4, and a pressure head 5; the box body 1 is provided with a guide rail 2, and the quick-change box 3 is arranged in the box. In the body 1, the upper end of the box body 1 is provided with a strut 4, and a pressure head 5 is provided on the strut 4, and the pressure head 5 corresponds to the quick change box 3 vertically.

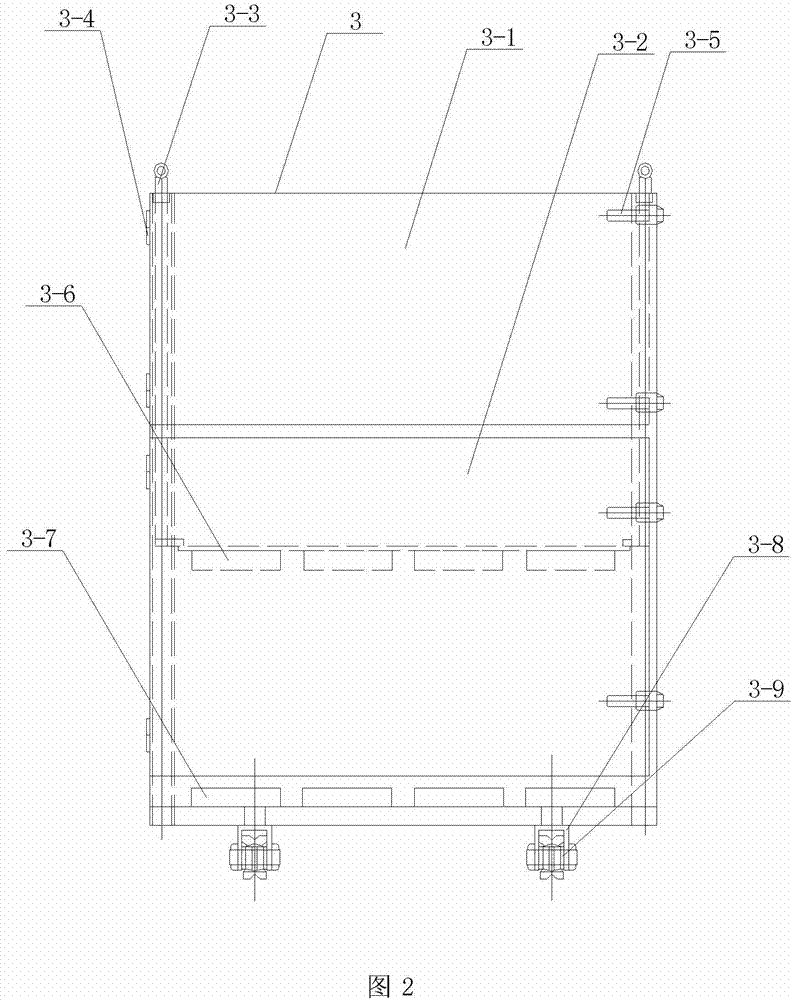

[0013] The quick change box 3 is composed of the upper half door 3-1, the lower half door 3-2, the pressure plate card 3-3, the cylindrical hinge 3-4, the pull buckle 3-5, the pressure plate 3-6, and the frame 3- 7. The supporting wheel seat 3-8 and the supporting wheel 3-9 are composed; the lower end of the upper door 3-1 is provided with the lower door 3-2, and the upper end of the upper door 3-1 is provided with pressure plate cards 3 respectively -3. One side of the quick chan

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap