Biomass small boiler

A small boiler and biomass technology, applied in lighting and heating equipment, fluid heaters, water heaters, etc., can solve the problems of inability to form effective drives, low energy efficiency and utilization, and inability to meet the economic cost of energy conversion for enterprises. , to achieve the effect of increasing the heat exchange area and saving energy expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0016] The present invention will be further described in detail below in conjunction with specific embodiments and drawings.

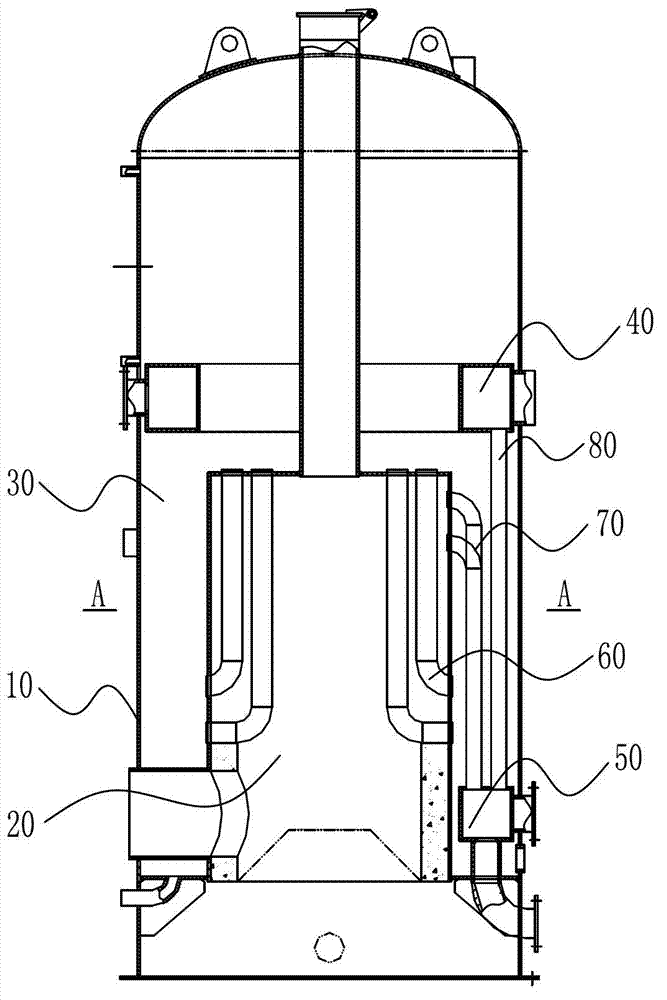

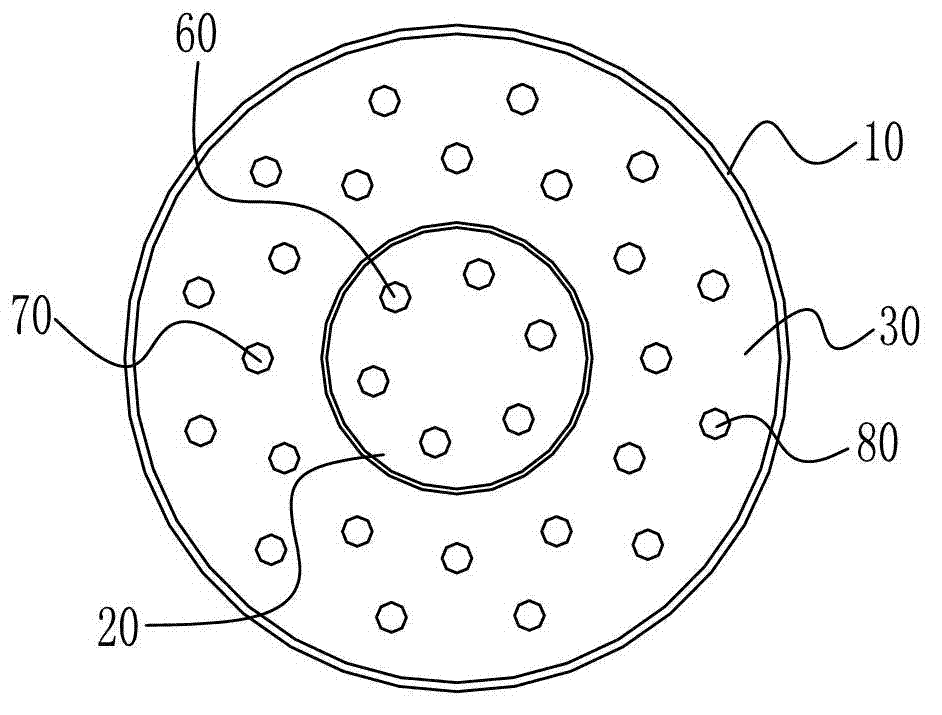

[0017] Kind of like figure 1 with figure 2 The small biomass boiler shown includes a furnace body 10 and a furnace shell 20 arranged in the furnace body 10. The inner wall of the furnace body 10 to the outer wall of the furnace shell 20 forms a closed water tank 30 containing boiler water, wherein The upper part and the lower part of the furnace body 10 are respectively provided with an upper flue 40 and a lower flue 50. The upper flue 40 is provided with a flue opening connected to the outside of the furnace body 10; The heat exchange pipe 60 of the furnace liner 20; a number of heat exchange fire pipes 70 leading out along the upper part of the furnace liner 20 and connected to the lower flue 50 are provided in the closed water tank 30, and several heat exchange pipes 70 are drawn from the lower flue 50 The heat exchange smoke pipe 80 connected to the u

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap