Circuit for realizing constant current control in primary control switch power converter

A switching power supply and primary side control technology, which is applied in the direction of converting DC power input to DC power output, converting AC power input to DC power output, and adjusting electrical variables, etc., can solve problems such as ineffective constant current control, and achieve Constant output current, suitable for a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific drawings and embodiments.

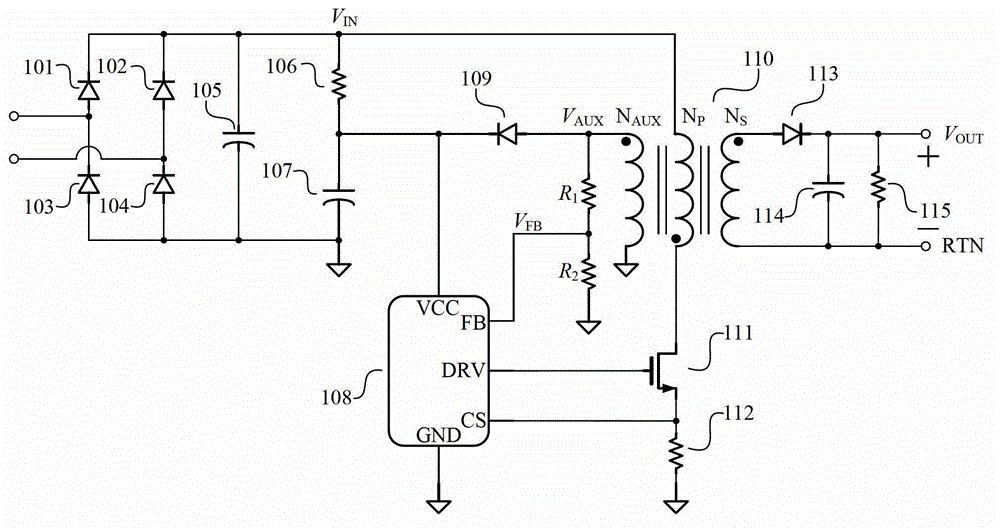

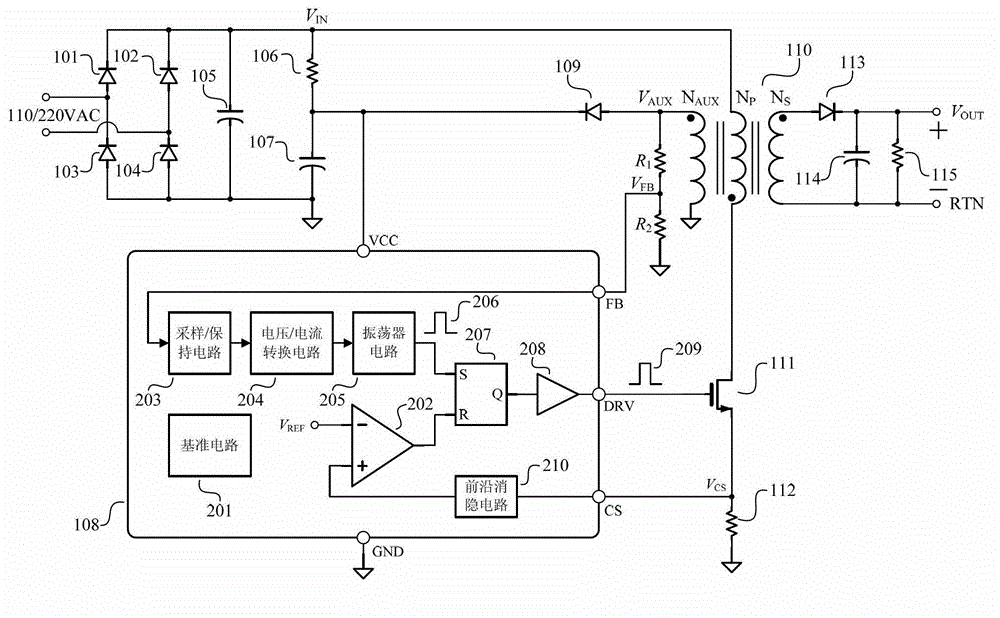

[0035] Such as figure 1 Shown: is the circuit schematic diagram of the existing primary side control switching power supply converter, which includes the first rectifier diode 101, the second rectifier diode 102, the third rectifier diode 103 and the fourth rectifier diode 104, the first rectifier diode 101 The cathode terminal is connected to the cathode terminal of the second rectifying diode 102, the anode terminal of the first rectifying diode 101 is connected to the cathode terminal of the third rectifying diode 103, and the anode terminal of the second rectifying diode 102 is connected to the cathode terminal of the fourth rectifying diode 104 The anode terminals of the third rectifier diode 103 and the fourth rectifier diode 104 are grounded to form a rectifier circuit for rectifying the input 110V or 220V AC. The cathode terminal of the first rectifier di

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap