Driving wheel system capable of realizing universal rotation

A technology of universal rotation and wheel train, which is applied in the direction of wheels, steering mechanism, wheel axle combination, etc., can solve the problem of limiting the steering angle of the steering wheel, and achieve the effect of reducing the weight of the whole vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

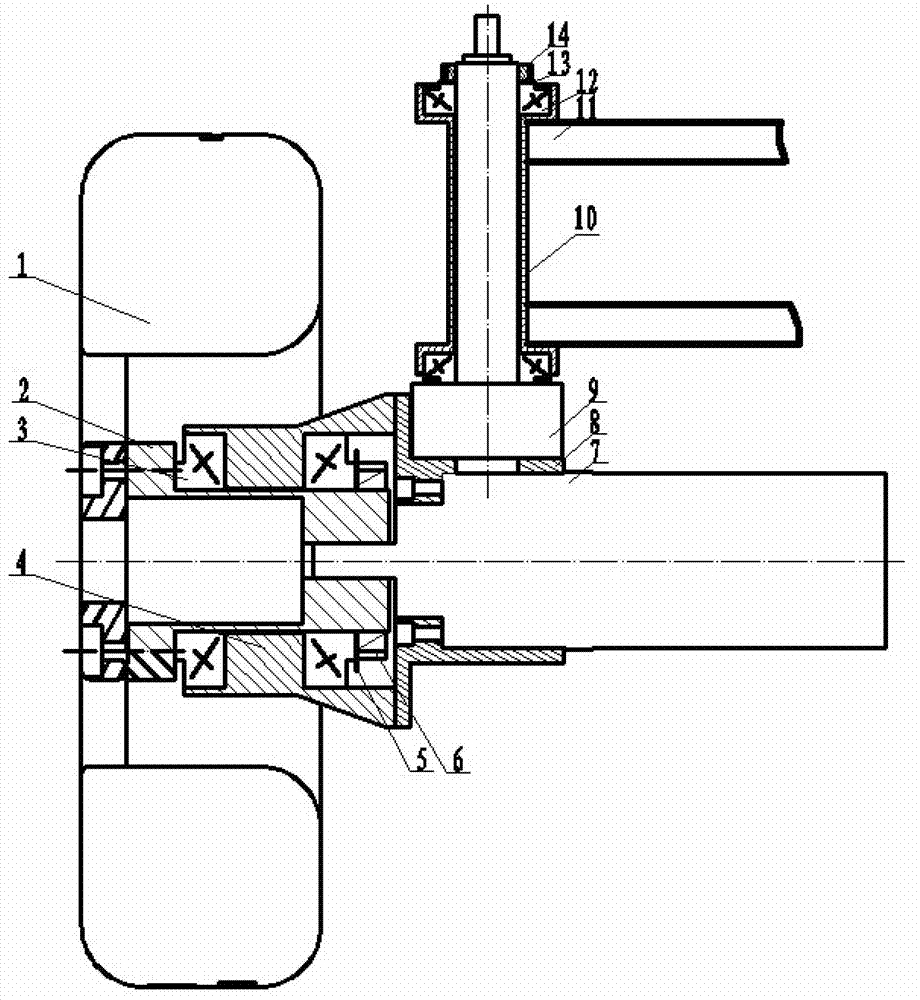

[0009] Such as figure 1 The shown wheel (1) and the axle (2) are fixedly connected by bolts, and a pair of axle tapered roller bearings (3) are installed on the axle (2) and the axle shell (4), through the axle round nut (6) and The wheel shaft round nut uses a stop washer (5) to limit the position of the wheel shaft tapered roller bearing (3) in the axial direction. The axle (2) and the wheel (1) rotate relative to the axle housing (4) through a pair of tapered roller bearings (3), and the axle (2) receives power input from the DC motor (7) to drive the wheel (1) to rotate.

[0010] The axle housing (4) and the motor fixing housing (8) are fixedly connected by bolts, the DC motor (7) and the motor fixing housing (8) are fixedly connected by hexagon socket head screws, the wheel axle housing (4), the motor fixing housing (8), the DC The motor (7) is assembled as an integral part. The steering shaft (9) is fixedly connected to the motor fixing case (8) by hexagon socket head cap

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap