Oily sewage and sludge separation device

A separation device and water sludge technology, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of unsatisfactory treatment effect and complex equipment structure, and achieve structural Simple, high extraction rate and extraction efficiency, good water treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described below with reference to the drawings. Elements and features described in one drawing or one embodiment of the present invention may be combined with elements and features shown in one or more other drawings or embodiments. It should be noted that representation and description of components and processes that are not related to the present invention and known to those of ordinary skill in the art are omitted from the drawings and descriptions for the purpose of clarity.

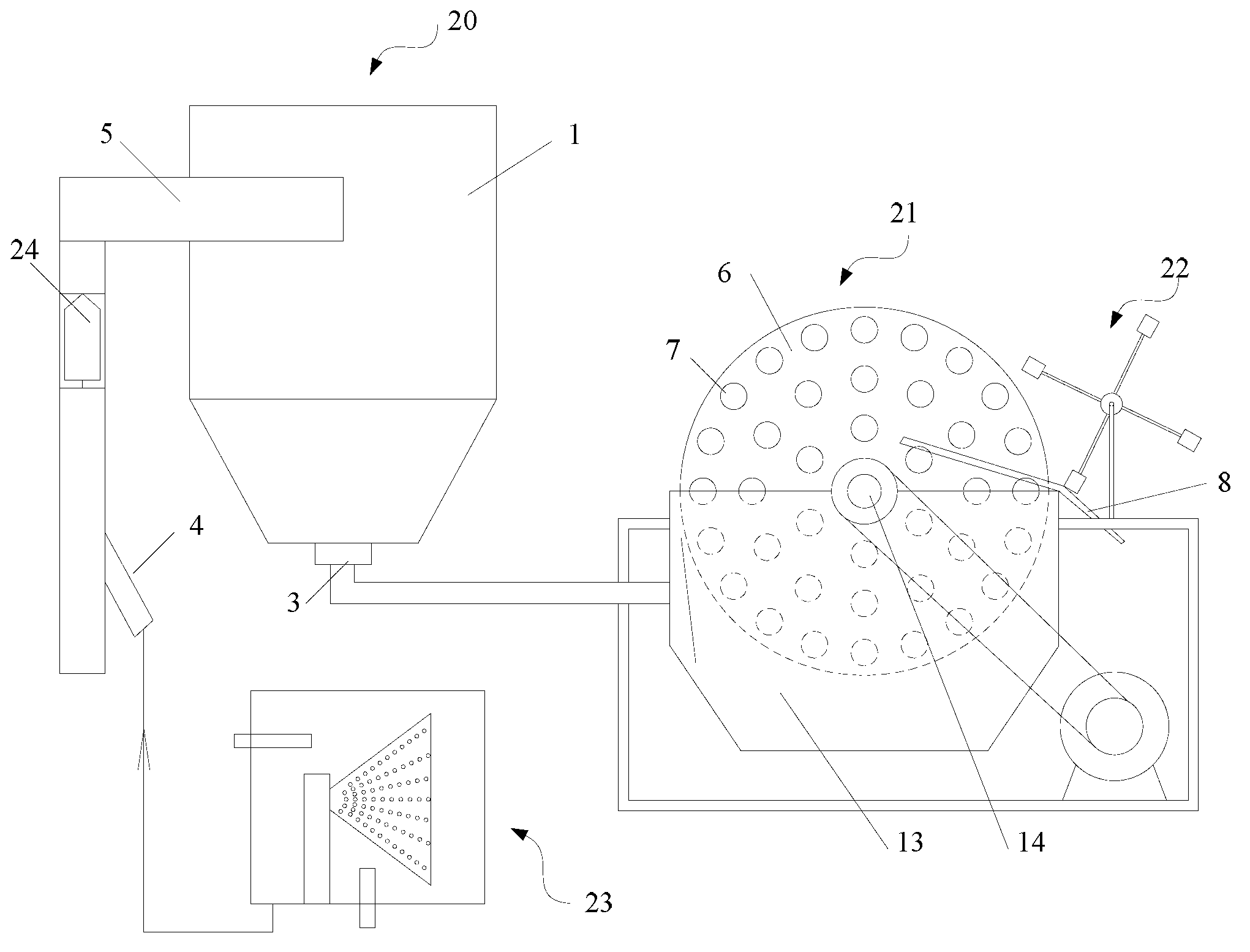

[0033] figure 1 Schematic diagram of the structure of the oily sewage sludge separation device provided by the embodiment of the present invention; as figure 1 As shown, the oily sewage sludge separation device provided in the embodiment of the present invention includes a reactor 20 and a magnetic mud-water separator 21 .

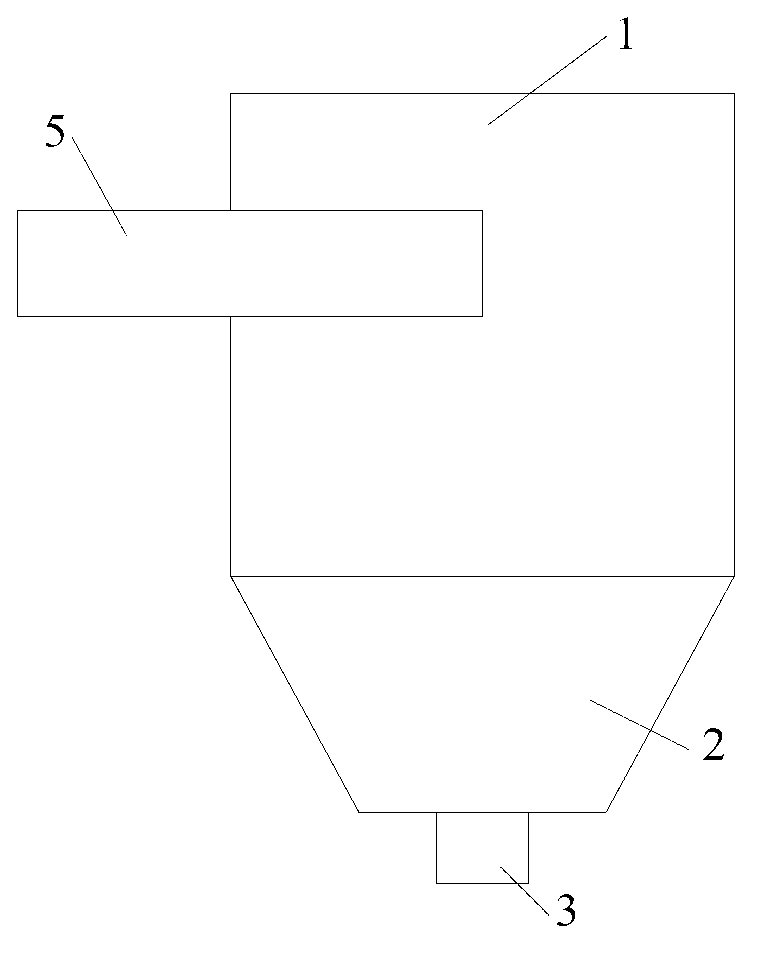

[0034] Wherein, the reactor 20 includes a reactor tank body 1 with a revolving body structure, the side wall of the reactor ta

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap