System and method for lead screw rope arrangement of well drilling winch

A lead screw and rope arranging technology, applied in the direction of the spring mechanism, hoisting device, etc., can solve the problems of knotting, waste, disordered wire rope ordering, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

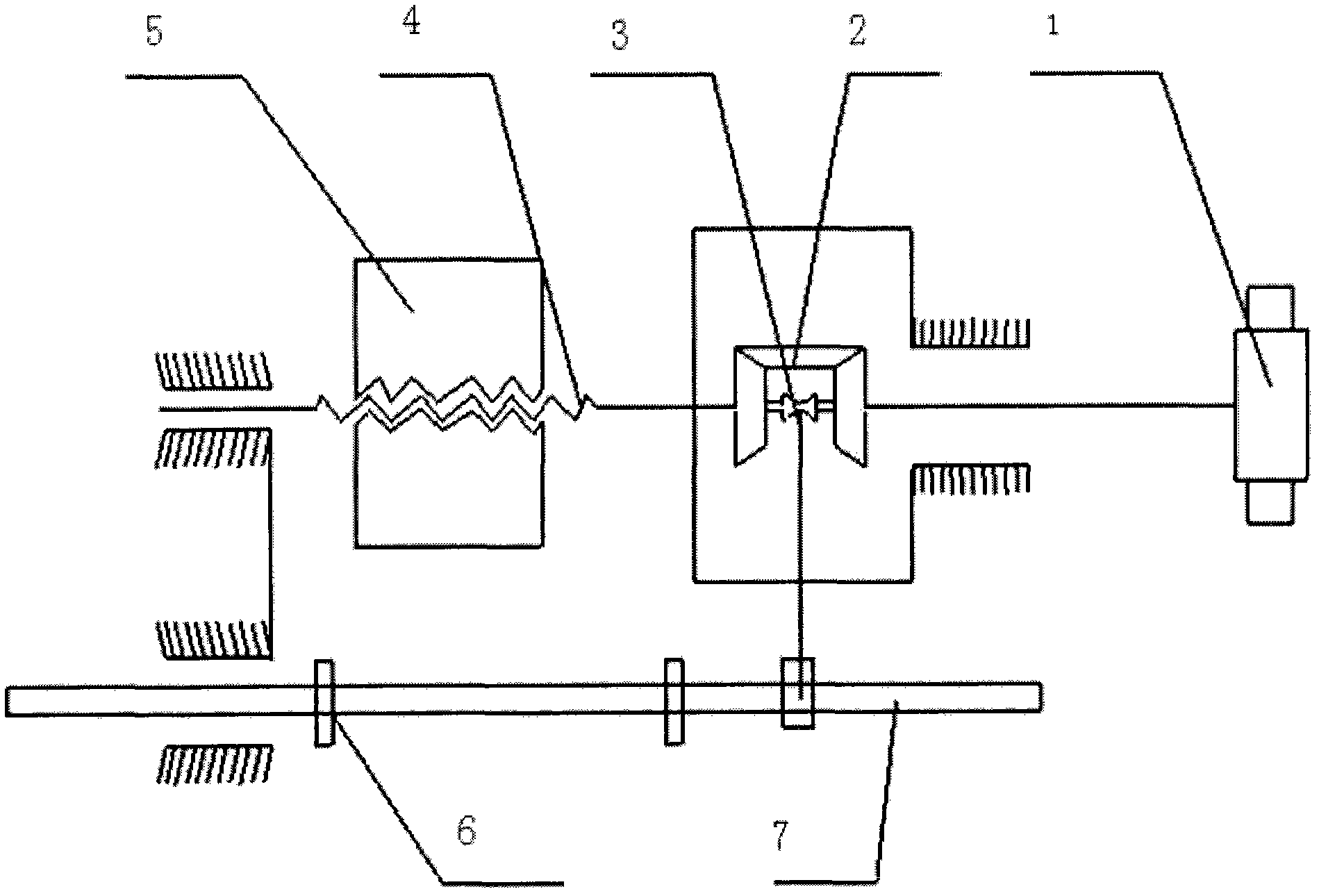

[0060] The lead screw rowing system of the drilling drawworks that the present invention relates to is as figure 1 As shown, it is mainly composed of a lead screw 4, a driving device 1 connected to the lead screw 4, and a nut 5 set on the lead screw 4, and a reversing device is also set on the lead screw 4.

[0061] The driving device 1 is a pull belt pulley.

[0062] Limiting blocks 6 are respectively arranged at both ends of the screw 4 .

[0063] The reversing device is mainly composed of a bevel gear 2 installed on the lead screw 4 and a reversing slider 3, and the bevel gear 2 and the reversing slider 3 are meshed.

[0064] The reversing slider 3 is connected with a reversing rod 7 .

[0065] The method for arranging ropes of a lead screw based on the above-mentioned lead screw arranging system comprises the following steps:

[0066] (a) First, the driving device 1 is turned on, and the driving device 1 drives the lead screw 4 to rotate;

[0067] (b) The rotation of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap