Gas meter with safety control function and safety control method

A safety control function, gas meter technology, applied in the direction of measuring devices, instruments, liquid/fluid solid measurement, etc., can solve the problems of poor adaptability, functional limitations, affecting the correctness and seriousness of alarms, etc., achieving low cost and easy promotion , the effect of rapid source guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

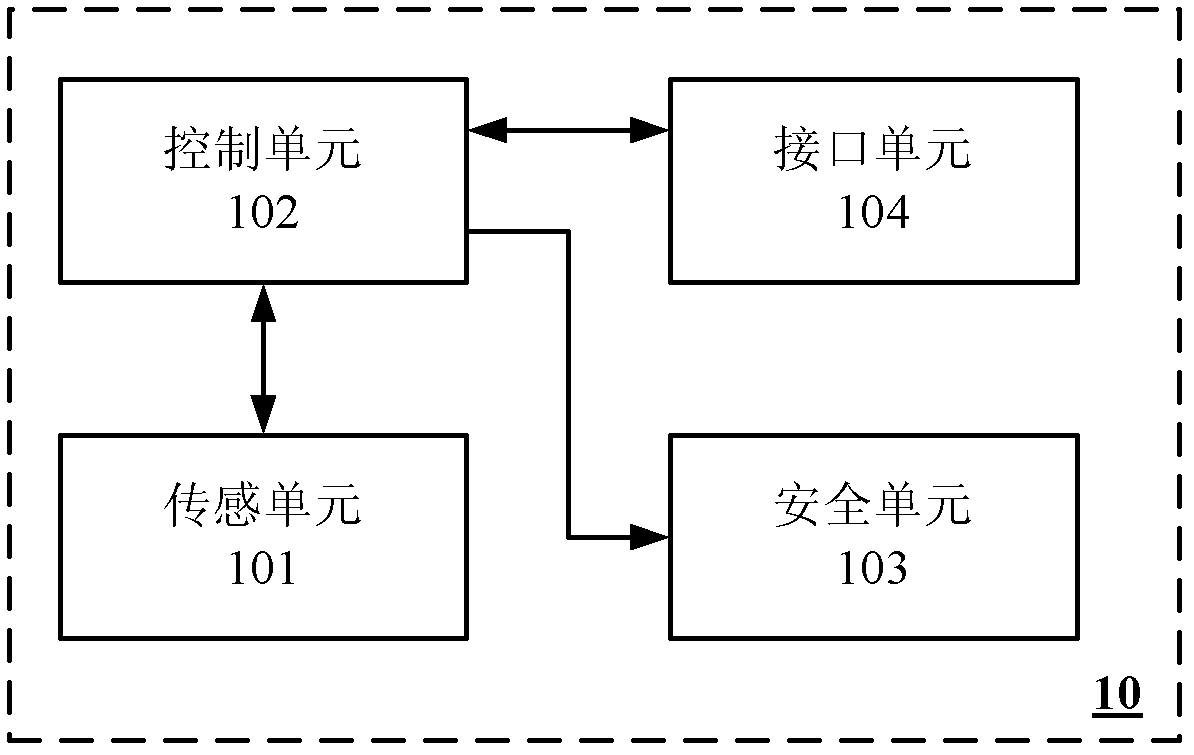

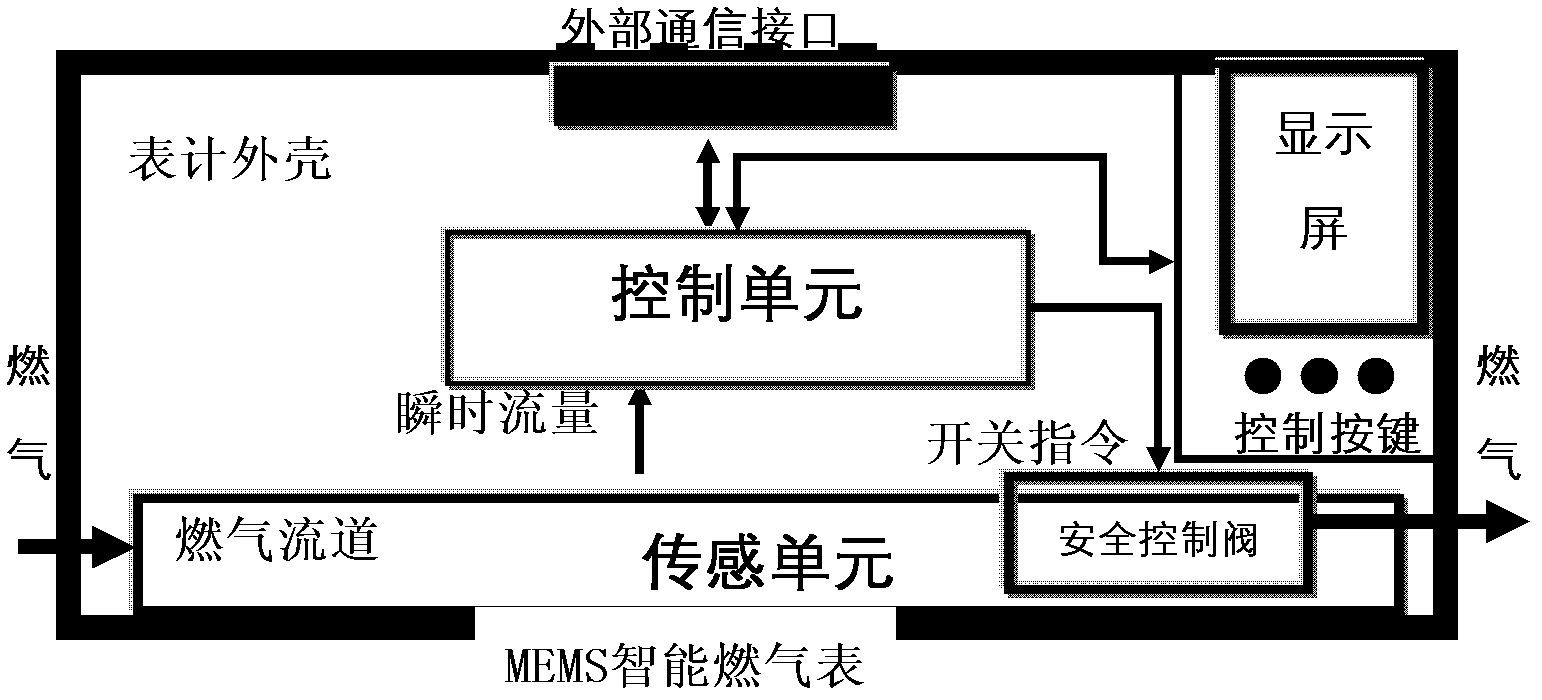

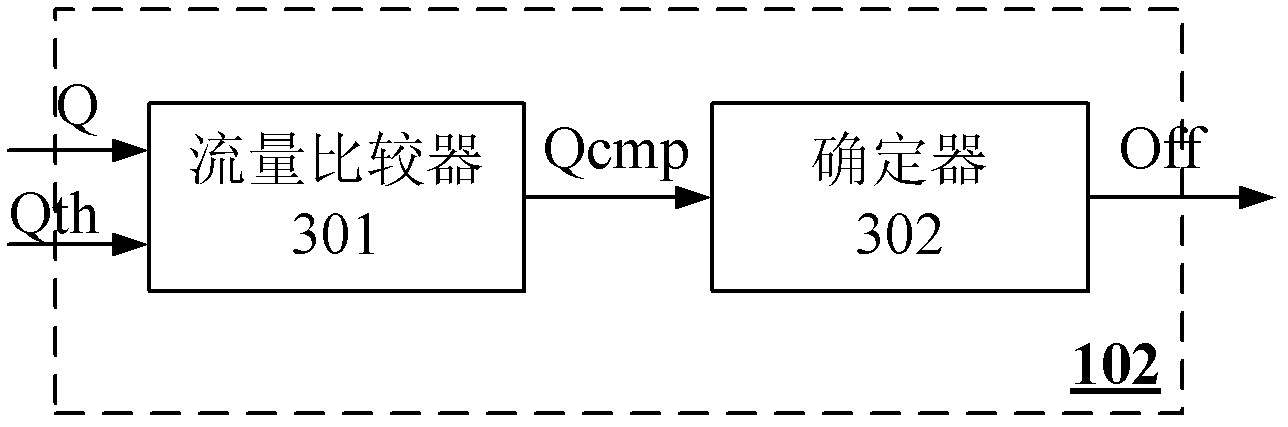

[0031] Hereinafter, the exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings, and the present invention is not limited to the following exemplary embodiments. In order to clearly describe the basic idea of the present invention, only the components, functions or steps closely related to the technical solutions of the present invention are shown in the drawings, and detailed descriptions of known technologies, functions, components or steps are omitted in the following description .

[0032] Based on the existing conventional metering and billing gas meters, the inventor proposed that a gas meter with safety control function can be realized by adding a safety control scheme based on flow detection to the existing gas meter. This kind of gas meter with safety control function can be implemented and installed in the form of a common gas meter, with low cost and easy promotion. It can also detect abnormal conditions in

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap