Coating device

A container and interface technology, which is applied in the direction of architecture and building construction, can solve the problems of reducing work efficiency, consuming manpower, and low painting efficiency, so as to achieve the effect of convenient painting operation and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

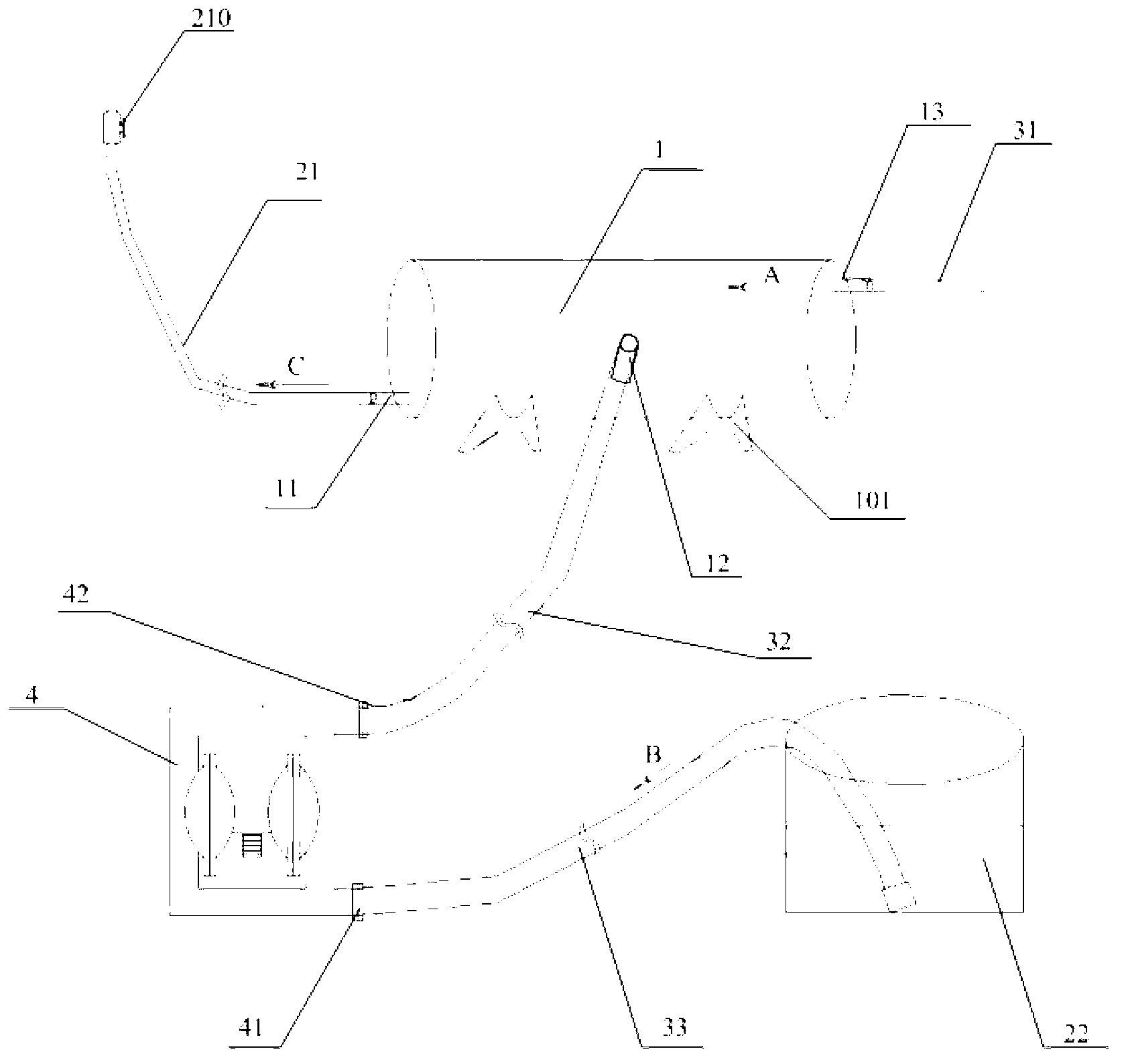

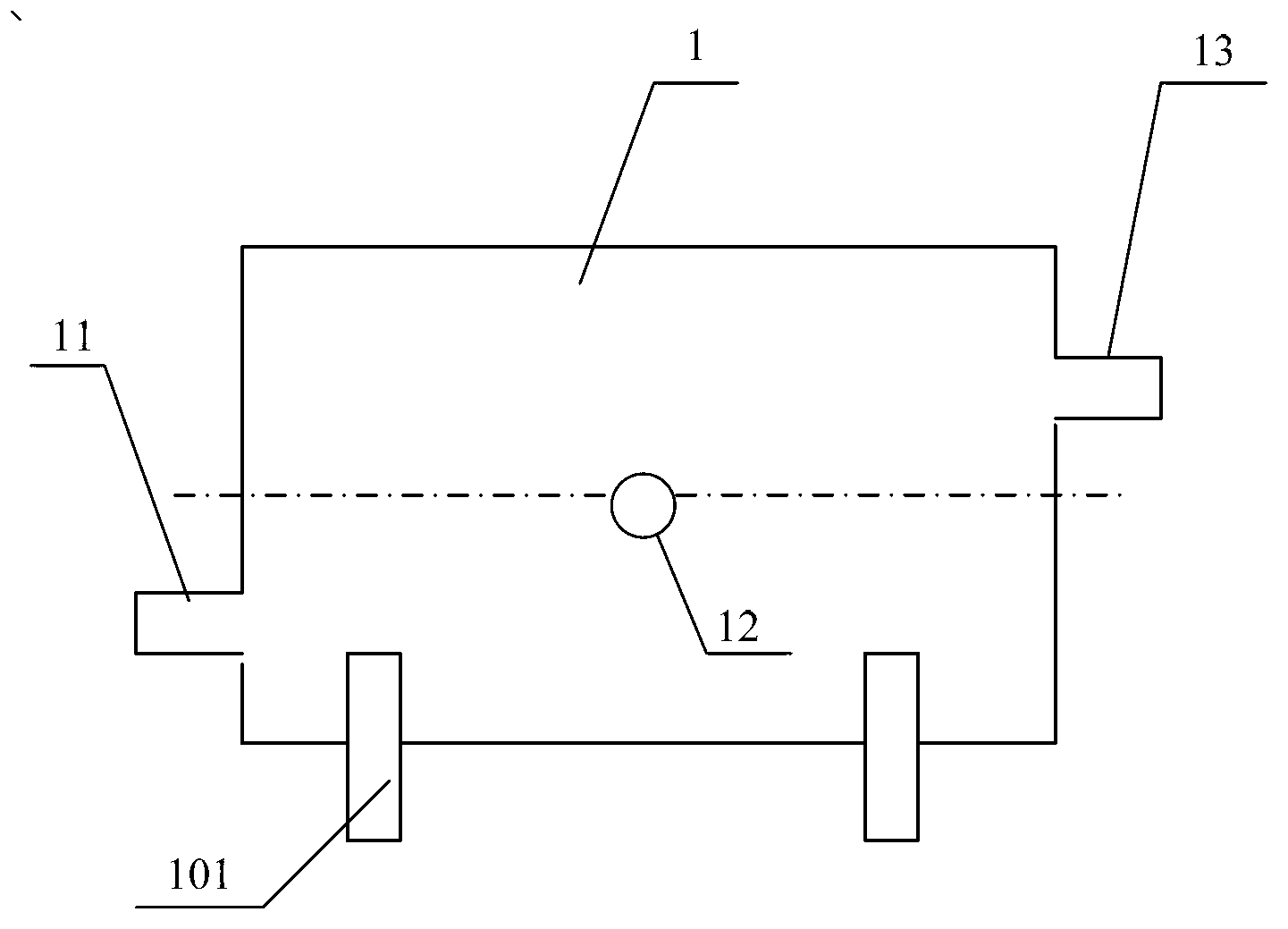

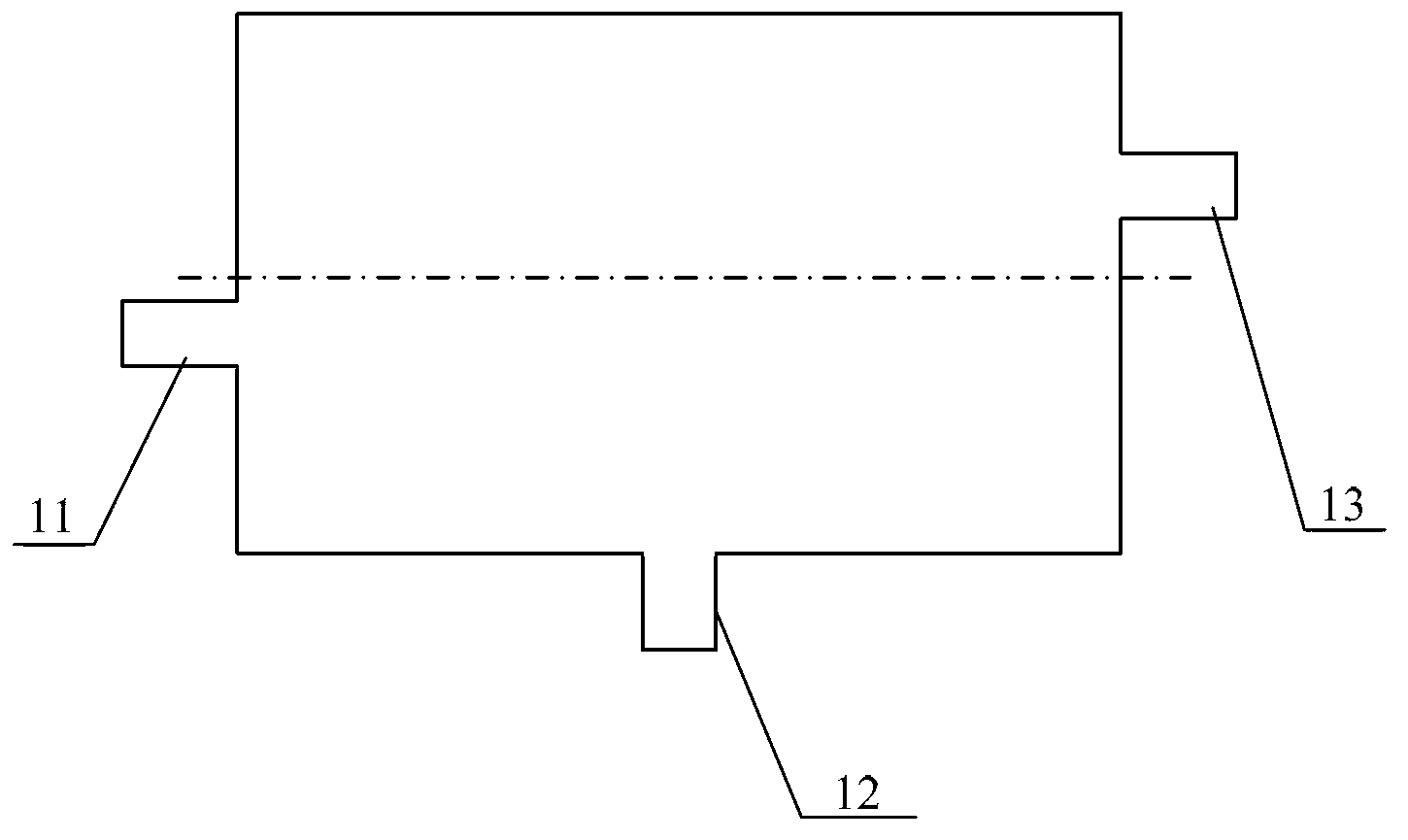

[0015] figure 1 It is a schematic diagram of the overall structure of an embodiment of the painting device of the present invention; figure 2 for figure 1 The front view of the tank body; image 3 for figure 2 top view of Figure 4 for figure 2 side view. Please refer to Figure 1-4 , the present embodiment provides a painting device, comprising: a closed tank body 1, the tank body 1 is provided with a first interface 11, a second interface 12 and a third interface 13 communicating with the inside of the tank body, the first interface 11 is Also connected with the paint output pipe 21; the pressure air source supply device (not shown in the figure) is used to store the pressure wind, and the air source supply device is connected to the third interface 13 of the tank body 1 through the first delivery pipe 31; the paint storage Device 22, used to accommodate and mix to form the paint; for pumping the paint in the paint container 22 to the pump 4 of the tank body 1, the in

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap