Novel anti-explosion door of vertical air shaft

A technology of explosion-proof doors and vertical air shafts, which is applied to the ventilation of mines/tunnels, mining equipment, and mining equipment. Simple structure, strong reliability, and the effect of avoiding the expansion of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

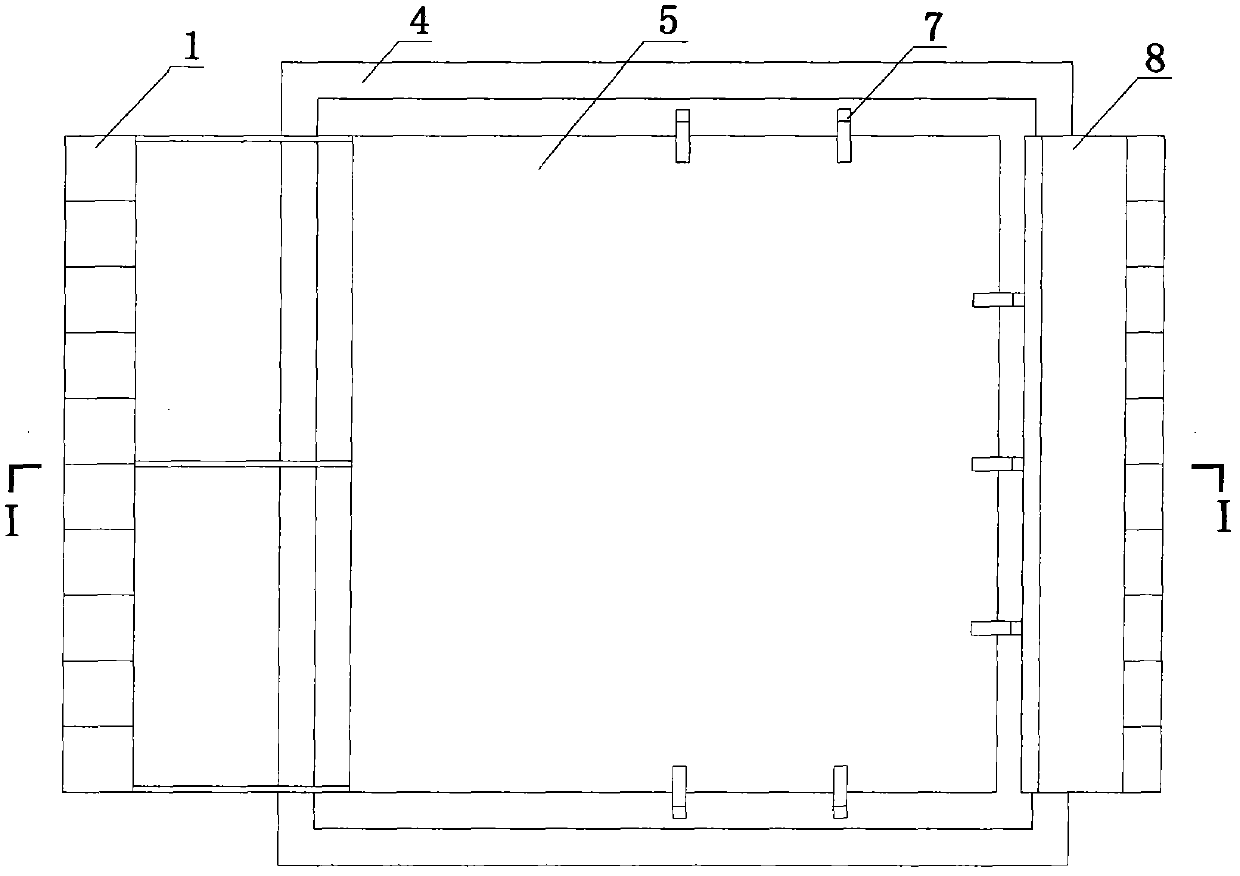

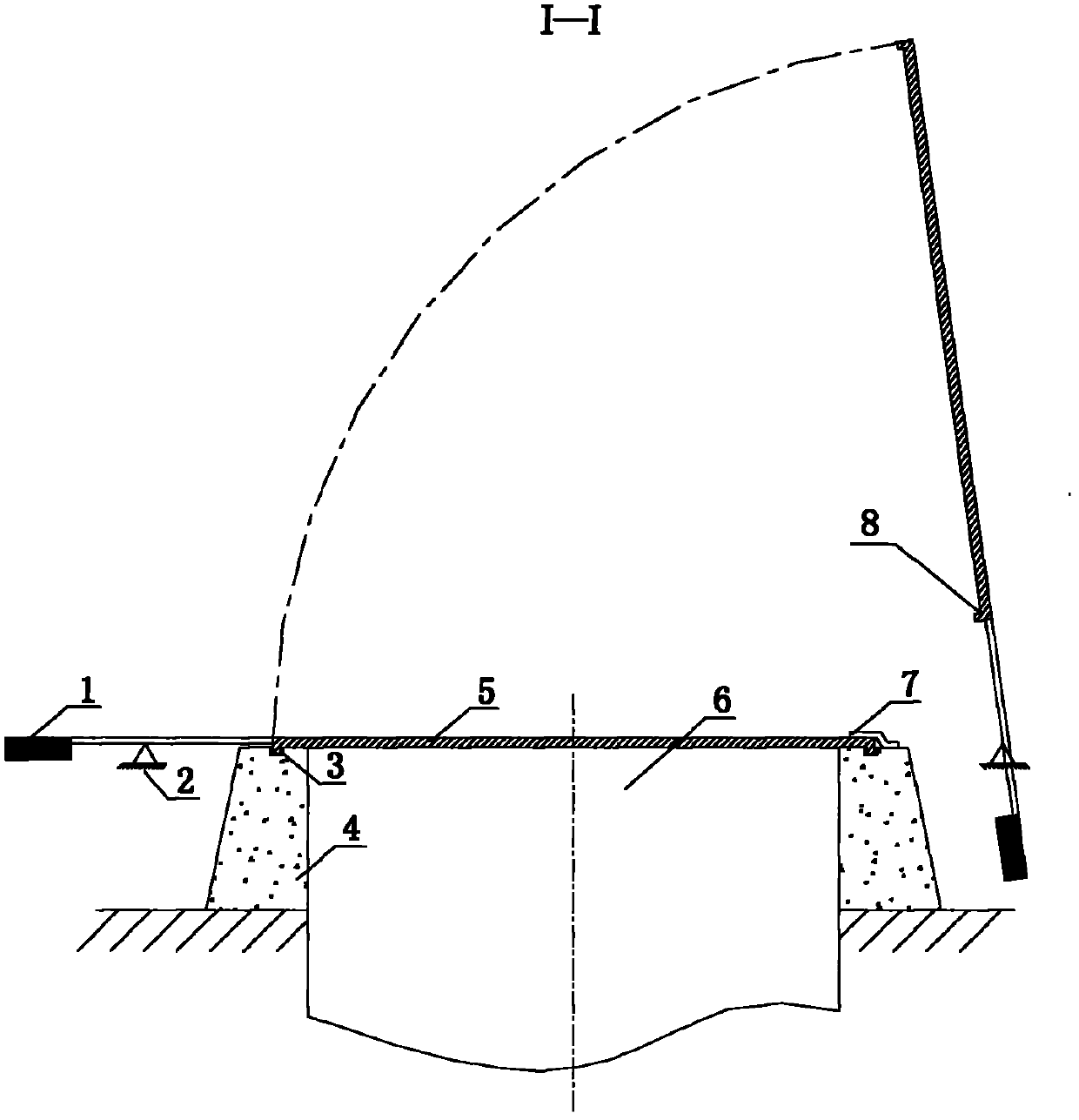

Image

Examples

Embodiment Construction

[0008] Below in conjunction with accompanying drawing, the implementation of the present invention is described in further detail:

[0009] The door body (5) is made of bursting disc and steel structure and equipped with a suitable counterweight (1) to form the main part of the explosion-proof door. The explosion-proof door passes through the rotary support shaft (2) on both sides of the air shaft lock plate (4). Turn on or off by turning. The explosion-proof door is sealed by the sealing liquid tank (3) to prevent air leakage from affecting the ventilation effect. Under normal circumstances, the explosion-proof door is kept closed by the negative pressure of the main fan. When the main fan fails and stops running, the explosion-proof door is lifted with the rotary support shaft (2) as the fulcrum under the action of the counterweight (1). Turn over to realize the natural wind pressure ventilation of the whole mine. When a gas or coal dust explosion accident occurs underground,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap