Shaft sleeve abrasion testing system

A wear test and shaft sleeve technology, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of single function, inability to simulate the working conditions of the shaft sleeve, low efficiency, etc., and achieve the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] It should be pointed out that the description and sequence of specific structures in this section are only descriptions of specific embodiments, and should not be considered as limiting the protection scope of the present invention. In addition, the embodiments in this section and the features in the embodiments can be combined with each other under the condition of no conflict.

[0043] Please refer to Figure 1 to Figure 11 , the embodiments and various implementation modes of the present invention will be described in detail below in conjunction with the accompanying drawings.

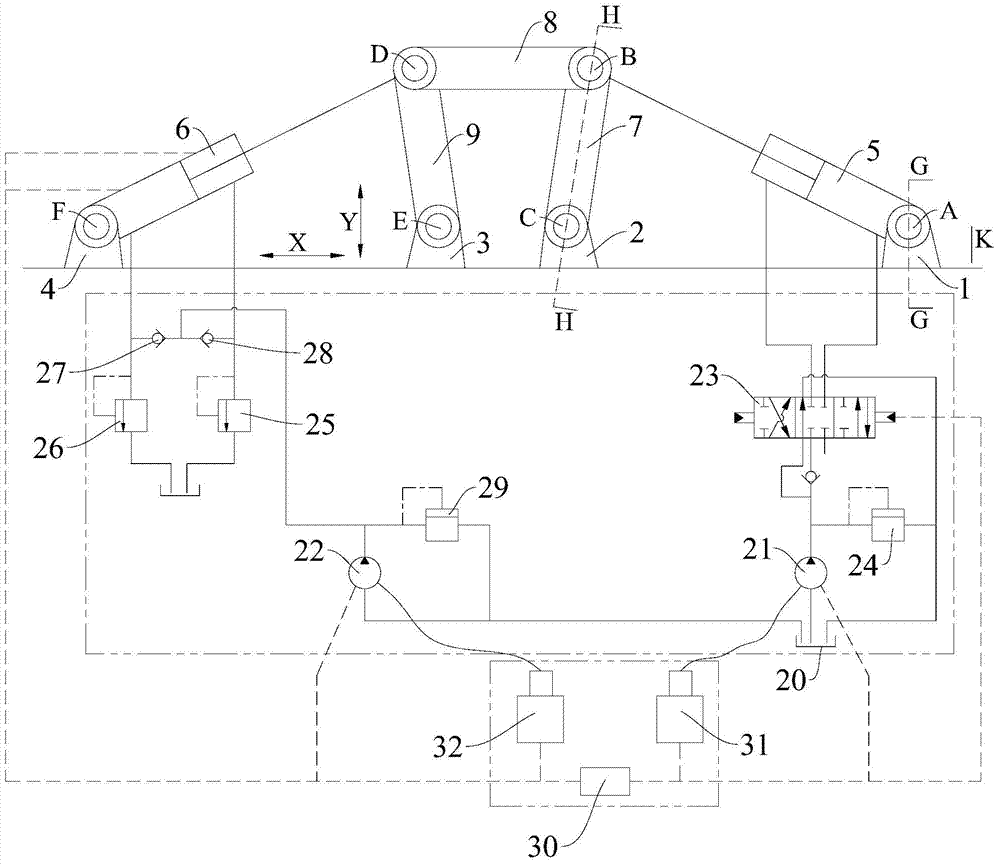

[0044] See figure 1 , and combined with figure 2 As shown, the shaft sleeve wear test system of the embodiment of the present invention is composed of three major subsystems: a mechanical system, a hydraulic system, and an electric control system.

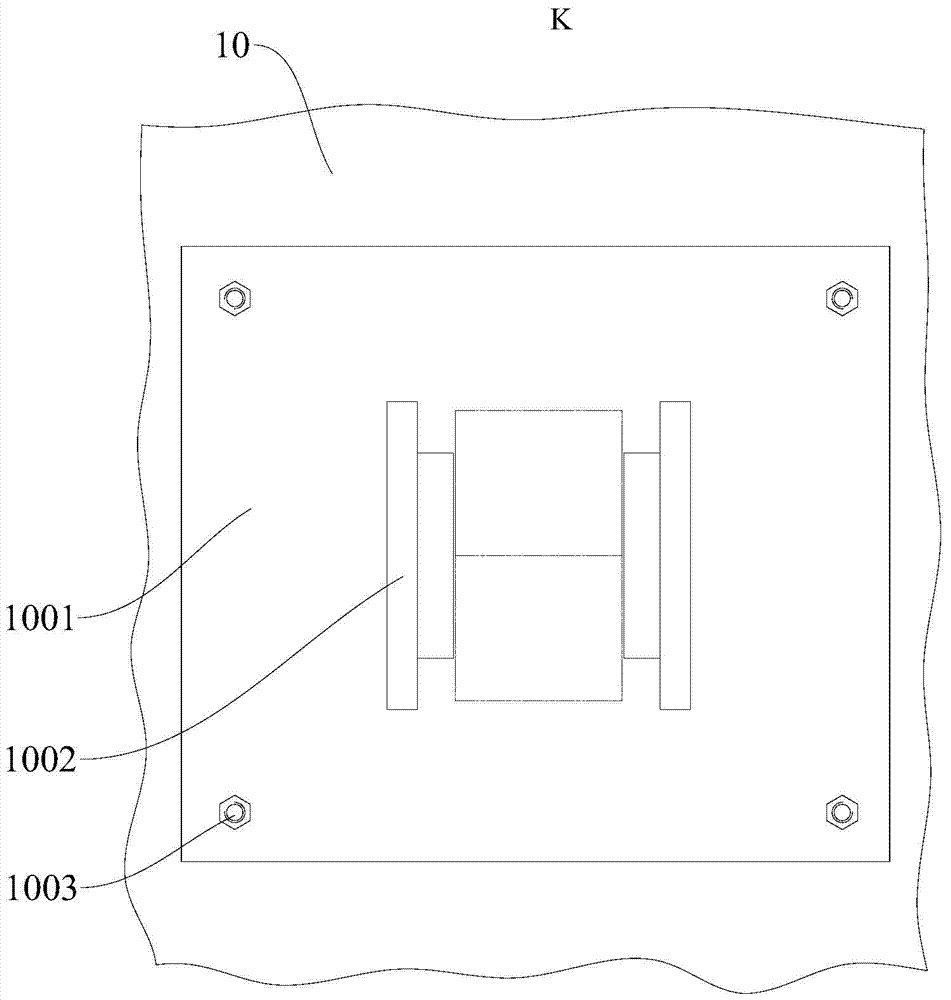

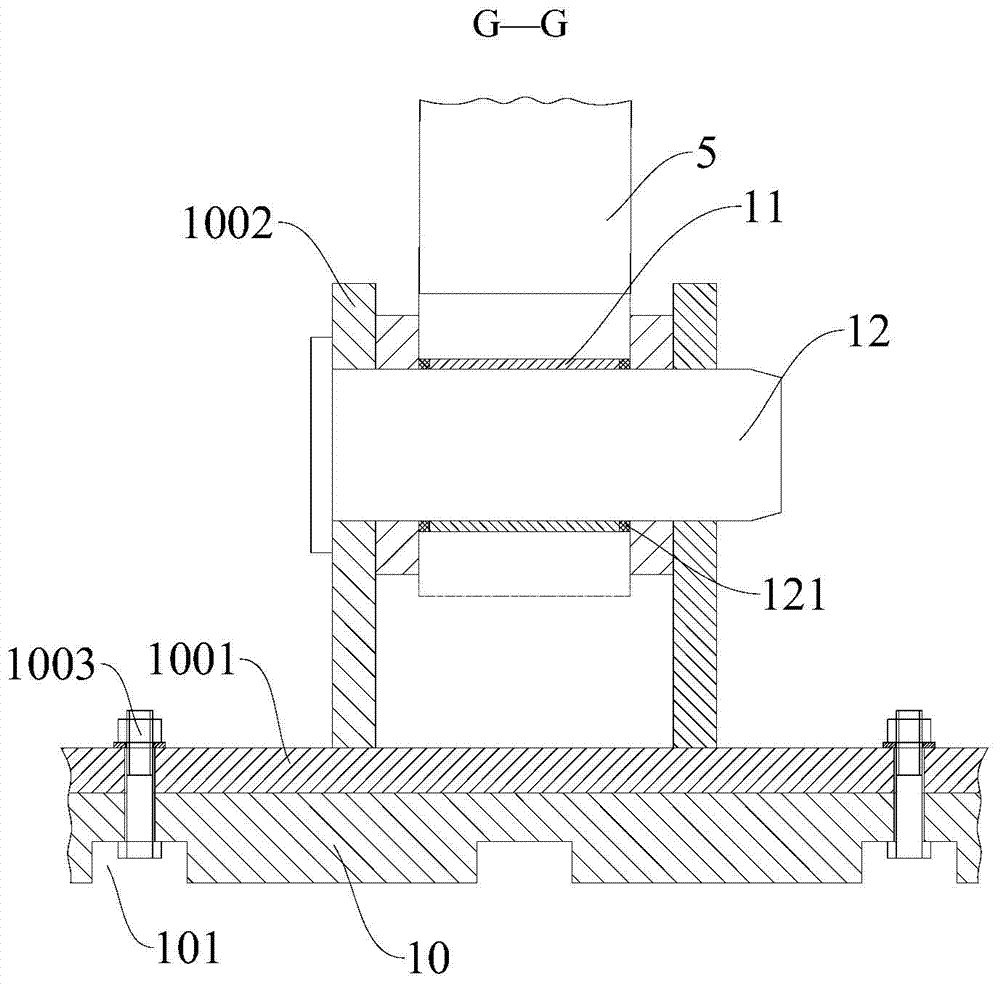

[0045] The mechanical system includes a working platform 10, a first mounting base 1, a second mounting base 2, a third mounting base 3, a fourt

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap