Solvent scavenger for a desolventizer toaster using a vapor recovery system

A technology for evaporating off machines and solvents, which can be used in dryers, lighting and heating equipment, drying, etc., and can solve problems such as waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

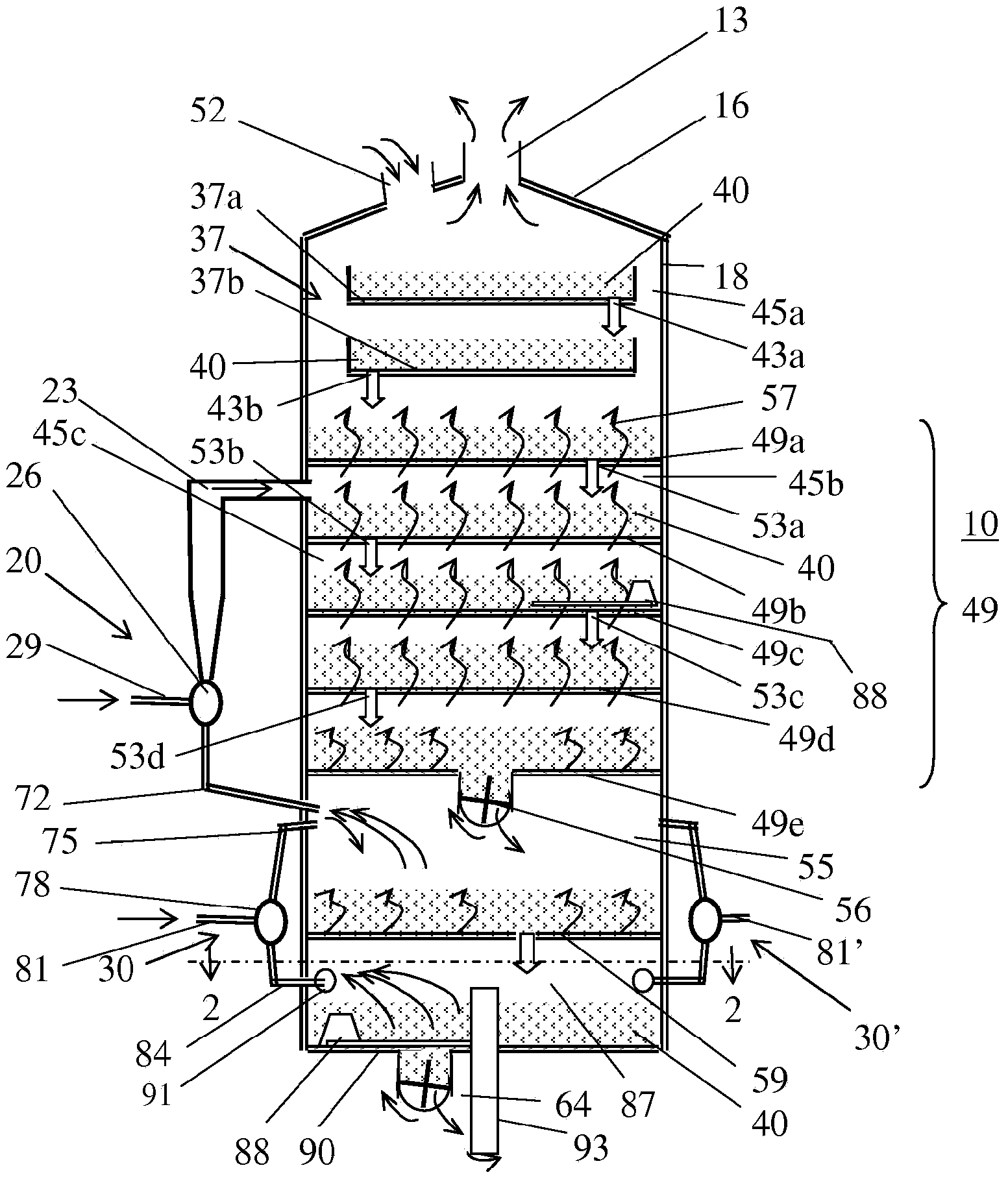

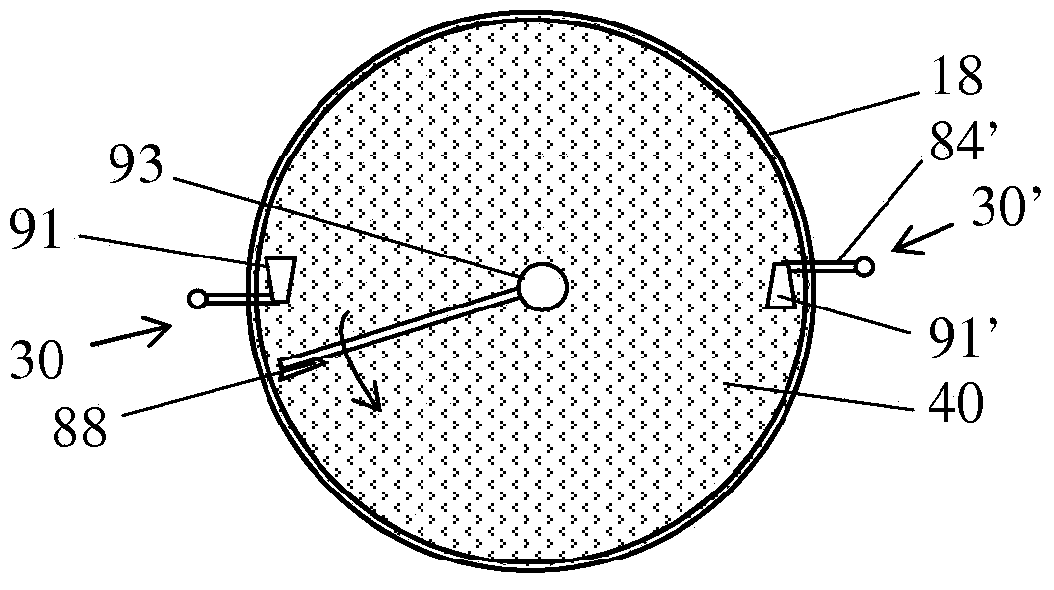

[0021] figure 1 and figure 2 An evaporator unit 10 is shown having many of the components shown in the aforementioned '250 patent. figure 1 and figure 2 The illustrated evaporator unit 10 includes a housing or enclosure 16 of generally cylindrical cross-section in which removal of solvent from the vegetable meal takes place. The figure shows meal stacks or layers 40 on various stages throughout the housing 16 for solvent removal.

[0022] The stage for solvent removal includes a plurality of vapor recovery (VR) trays 37a and 37b, 49a-49e and tray 59, collectively referred to as vapor recovery tray sets 37, 49 and 59, respectively. The sets of trays 37 , 49 and 59 are all used to support the stack 40 of multiple layers of meal during passage of the meal through the unit 10 .

[0023] The tray groups 37, 49 and 59 and the ply 90 are all hollow. Steam flows into and through the sets of trays 37, 49 and 59 and the deck 90 to heat the meal heap 40 they hold, thereby evaporat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap