Process for the preparation of diene polymers or random vinylarene-diene copolymers

A technology of vinyl aromatic hydrocarbon and diene copolymer, applied in the field of preparing diene polymer or random vinyl aromatic hydrocarbon-diene copolymer

- Summary

- Abstract

- Description

- Claims

- Application Information

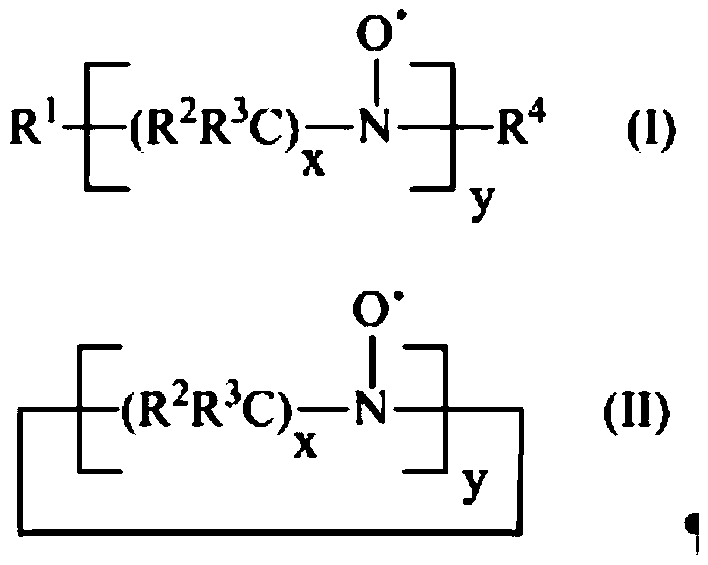

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] Embodiment 1 (comparison)

[0101] 600 grams of anhydrous cyclohexane (Bitolea), followed by 27 grams of freshly distilled anhydrous 1,3-butadiene (Versalis SpA) were introduced into a 1 liter vessel equipped with a jacket for circulation of a temperature-controlled fluid. in a stirred reactor. The reactor was equipped with a system for continuous measurement of the UV-Vis absorption spectrum of the polymer solution, which functioned as described in Example 5. The temperature of the reaction mixture was thermostatically controlled to 80°C and kept constant within ±4°C throughout the duration of the test. Then, 0.5 mmol of n-butyllithium (Aldrich) were introduced: the reaction conditions were maintained for 60 minutes, at the end ethanol (Carlo Erba) was introduced in an equimolecular amount relative to the amount of n-butyllithium introduced. Then, the obtained polymer solution was discharged from the reactor, and a phenolic antioxidant (from Ciba 1520, in an amount

Embodiment 2

[0103] Embodiment 2 (comparison)

[0104] 600 grams of anhydrous cyclohexane (Bitolea), followed by 27 grams of freshly distilled anhydrous 1,3-butadiene (Versalis SpA) were introduced into a 1 liter vessel equipped with a jacket for circulation of a temperature-controlled fluid. in a stirred reactor. The reactor was equipped with a system for continuous measurement of the UV-Vis absorption spectrum of the polymer solution, which functioned as described in Example 5. The temperature of the reaction mixture was thermostatically controlled to 120°C and kept constant within ±4°C throughout the duration of the test. Then, 0.5 mmol of n-butyllithium (Aldrich) were introduced: the reaction conditions were maintained for 60 minutes, at the end ethanol (Carlo Erba) was introduced in an equimolecular amount relative to the amount of n-butyllithium introduced. Then, the obtained polymer solution was discharged from the reactor, and a phenolic antioxidant (from Ciba 1520, in an amount o

Embodiment 3

[0106] Embodiment 3 (invention)

[0107] 600 g of anhydrous cyclohexane (Bitolea), followed by 27 g of freshly distilled anhydrous 1,3-butadiene (Versalis SpA) and then obtained as described in US patent application US 2010 / 0240909 0.5 mmol of 1,1,3,3-tetraethylisoindol-2-yl-oxyl (TEDIO) was introduced into a 1 liter stirred reactor equipped with a jacket for circulation of a temperature-controlled fluid. The reactor was equipped with a system for continuous measurement of the UV-Vis absorption spectrum of the polymer solution, which functioned as described in Example 5. The temperature of the reaction mixture was thermostatically controlled to 120°C and kept constant within ±4°C throughout the duration of the test. Then, 0.5 mmol of n-butyllithium (Aldrich) was introduced to obtain about 1:1 ratio of 1,1,3,3-tetraethylisoindol-2-yl-oxyl (TEDIO) and active n-butyllithium Molar ratio between the amounts: The reaction conditions were maintained for 60 minutes, at the end of w

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap