Coiler type condenser

A condenser and coiled tube technology, applied in the field of coiled tube condensers, can solve the problems of poor heat transfer effect and heavy equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

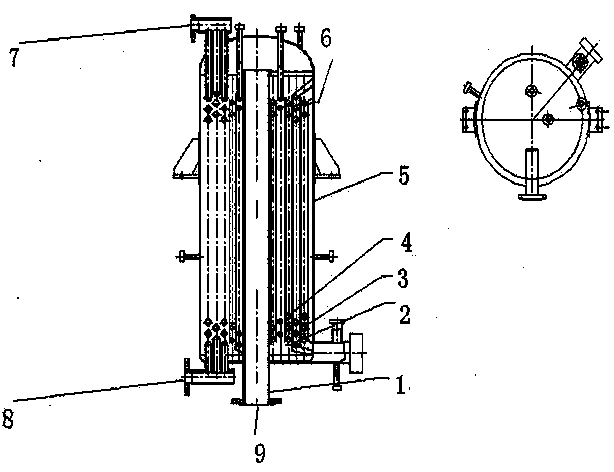

[0008] The present invention will be described in further detail in conjunction with the accompanying drawings. As shown in the figure, a coiled tube condenser, a coiled tube condenser, consists of an inner cylinder 1, condensing coils 2, 3, 4, cylinder 5, material preheating coil 6, cooling water outlet 7, cooling water The inlet 8 and the secondary steam inlet 9 are composed. 30°C water enters the cylinder body 5 from the cooling water inlet 8, and the temperature of the working water rises slightly after passing through the condensing coils 2, 3, and 4. After passing through the material preheating coil 6, the temperature of the water discharged through the cooling water outlet reaches 36°C, and the steam generated The secondary steam enters the inner tube 1 from the secondary steam inlet 9, and the secondary steam enters the condenser from the inner tube 1 and enters fresh milk (feeding temperature of fresh milk shall not be higher than 5°C) and cooling water (cooling wate

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap