Centering and leveling work platform for high-precision cylindricity measuring instrument

A workbench and cylindricity technology, applied in the field of measurement and detection, can solve the problems affecting cylindricity measurement accuracy, low feed accuracy, complex structure, etc., and achieve the effects of improving adjustment resolution, centering accuracy, and adjustment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

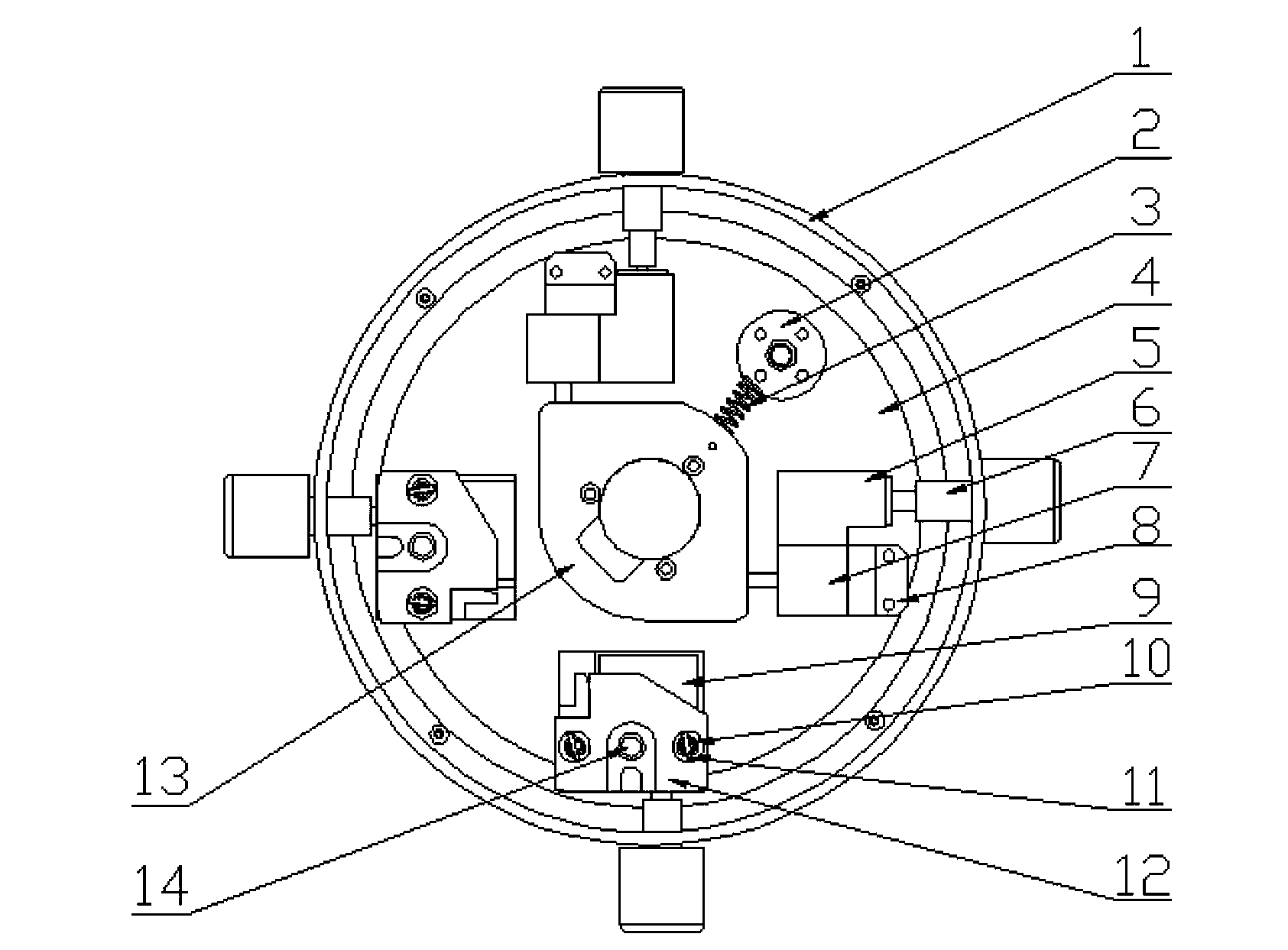

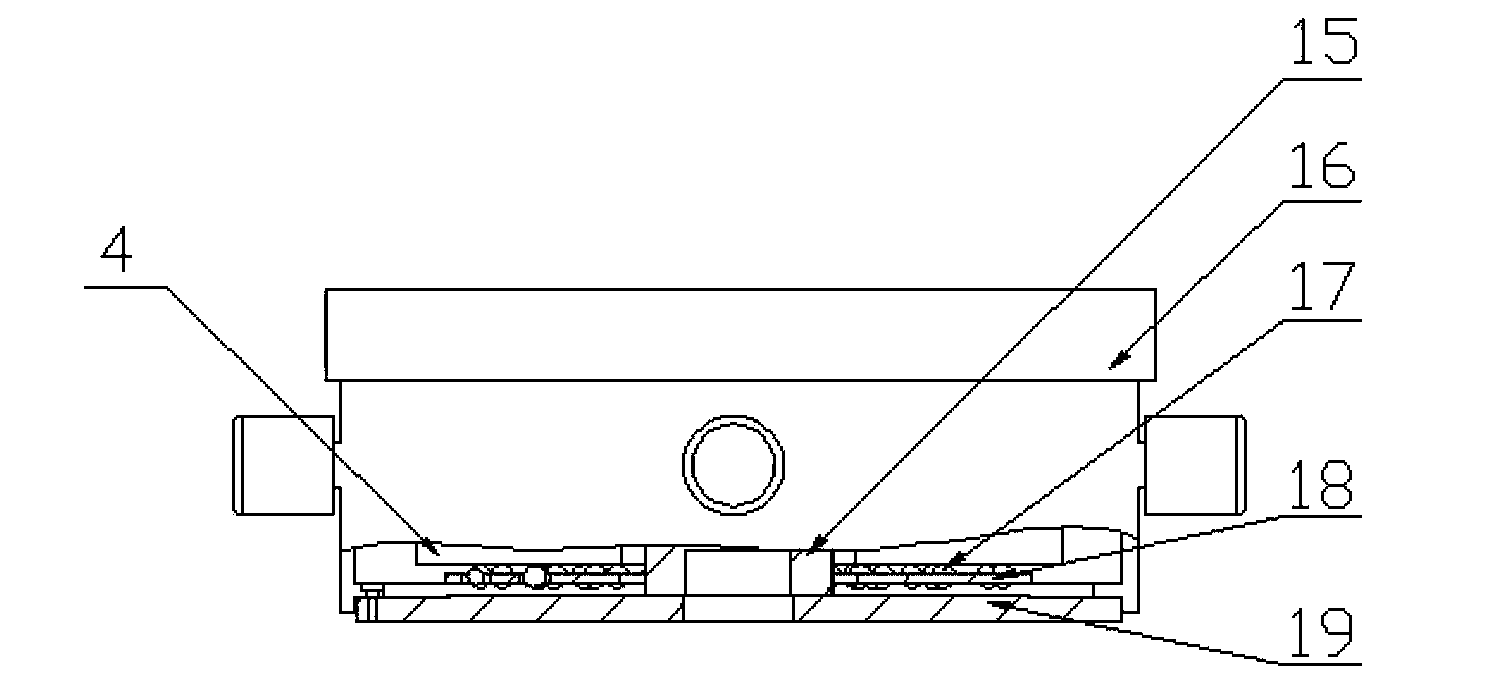

[0050] A self-aligning and leveling workbench for a high-precision cylindricity meter of the present invention will be introduced below in conjunction with the accompanying drawings and embodiments:

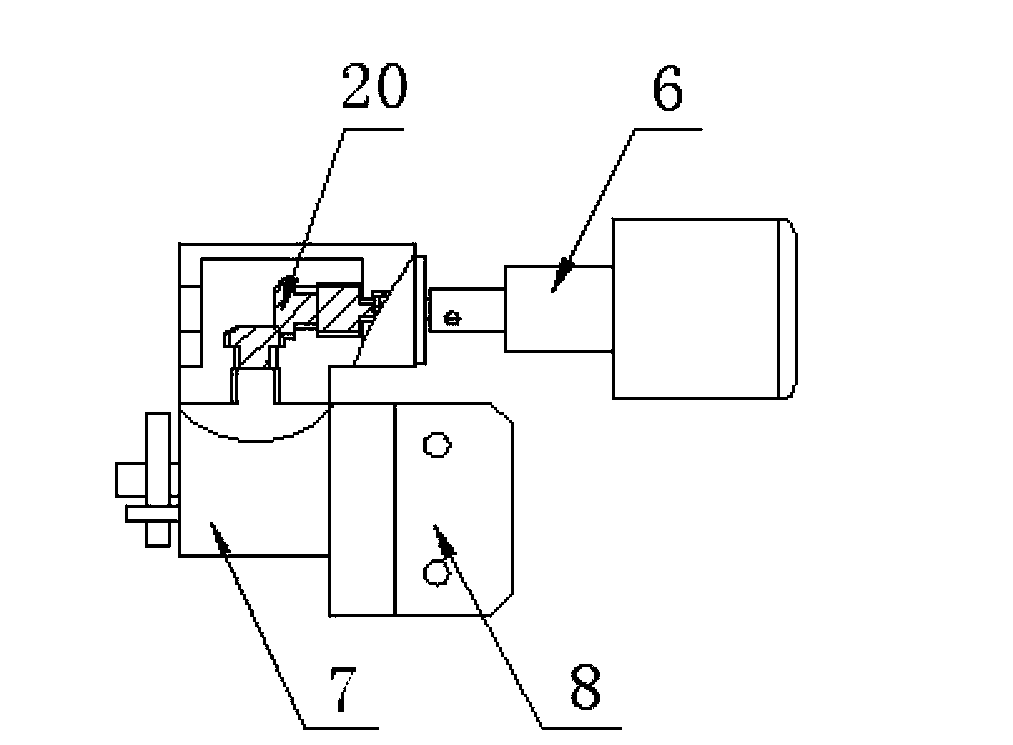

[0051]A centering and leveling workbench for a high-precision cylindricity meter, including a centering device, a leveling device, a workbench shell 1, a fixed steel ball support 2, a centering pretension spring 3, an intermediate mounting plate 4, an intermediate Mounting disc fixture 13, adjusting platform pressure column 15, self-aligning platform upper cover 16, middle mounting disc bottom steel ball 17, self-aligning ball disc 18, self-aligning platform base 19, cylindrical guide block 23.

[0052] The centering device is composed of adjusting hand wheel 6, self-aligning worm gear box 7, self-aligning worm gear box fixing seat 8, bevel gear steering box 5, self-aligning feed head block 21, and self-aligning feed head 22 . The bevel gear steering box 5 is a rectangular parallel

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap