Automatic uncoiler and roller shearing machine speed matching control system

An automatic control system and speed matching technology, applied in automatic control devices, metal rolling, manufacturing tools, etc., can solve the problems of small coils, increased rotational speed, and low degree of automation of the uncoiler, so as to reduce the scrap rate and improve the The effect of production efficiency and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

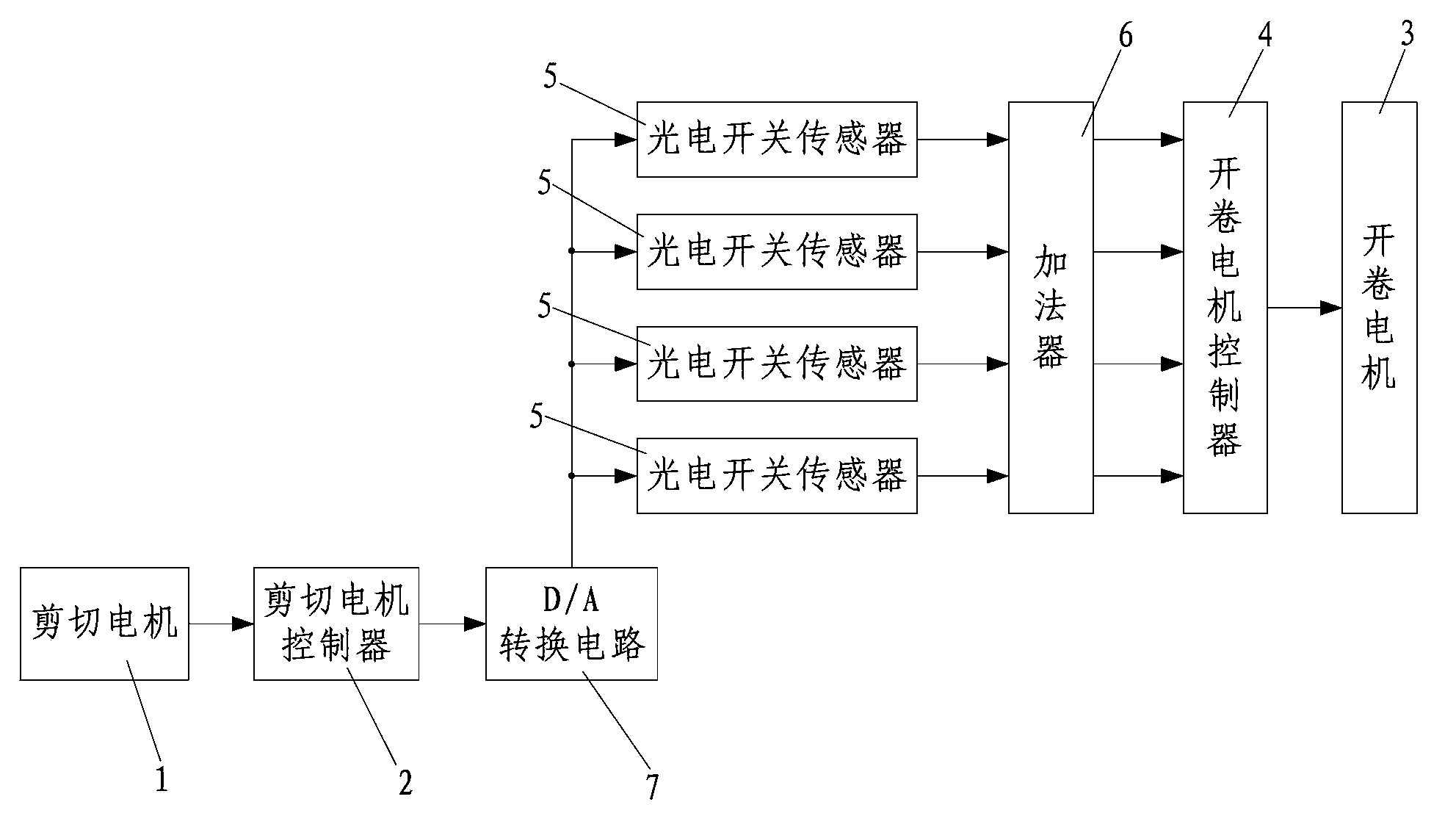

[0020] Such as figure 1 As shown, the present invention includes a shearing motor controller 2 for controlling the shearing motor 1 of the shearing machine and a speed feedback function and an uncoiling motor controller 4 for controlling the uncoiling motor 3 of the uncoiler, And a plurality of photoelectric switch sensors 5 that are installed on the inner wall of the looper pit at intervals up and down and an adder 6 that is all connected to the output terminals of a plurality of photoelectric switch sensors 5; the speed feedback signal output terminal of the shear motor controller 2 A D / A conversion circuit 7 is connected, and the output end of the D / A conversion circuit 7 is connected to the input ends of a plurality of photoelectric switch sensors 5 .

[0021] In this embodiment, the number of photoelectric switch sensors 5 is 3-6. Preferably, the number of photoelectric switch sensors 5 is four.

[0022] The working principle and working process of the present inventio

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap