Cambered case with good heat dissipation

A chassis and arc technology, applied in the field of heat dissipation arc chassis, can solve the problems of lack of air duct guiding device, lack of novelty, and the effect of fans cannot be well exerted, so as to achieve air duct optimization, fan efficiency improvement, and heat dissipation. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and example the present invention will be further described:

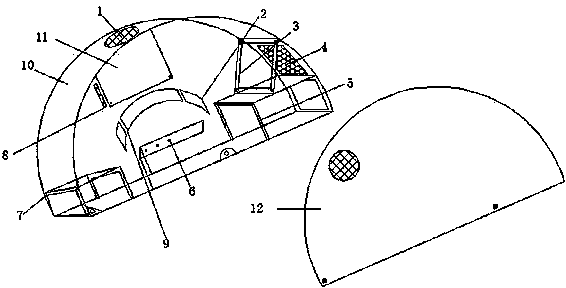

[0013] Such as figure 1 As shown, the heat dissipation arc chassis includes: ventilation net 1, baffle plate 2, fan fixing frame 3, honeycomb ventilation net 4, optical drive fixing bracket 5, hard disk fixing bracket 6, power supply fixing bracket 7, expansion card fixing platform 8, hard disk connection The wire passes through the port 9, the main body of the case 10, the main board fixing platform 11 and the side cover 12 of the case. The power supply fixing frame 7, the expansion card fixing platform 8 and the main board fixing platform 11 are fixed in the inner cavity of the chassis main body 10 by screws, the side cover 12 of the chassis is connected with the chassis main body 10 by screws, and the honeycomb ventilation net 4 is inlaid on the surface of the chassis main body.

[0014] Preferably, the chassis body is arc-shaped.

[0015] Preferably, the baff

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap