Sewage treatment reaction device in combination of activated-sludge method and biofilm method

A technology of activated sludge method and biofilm method, applied in the direction of aerobic and anaerobic process treatment, can solve the problems of easy sludge loss, low processing load, deterioration, etc., to reduce sludge loss, resist impact load, Good adhesion and growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] The invention is a novel sewage treatment reaction device combining activated sludge method and biofilm method.

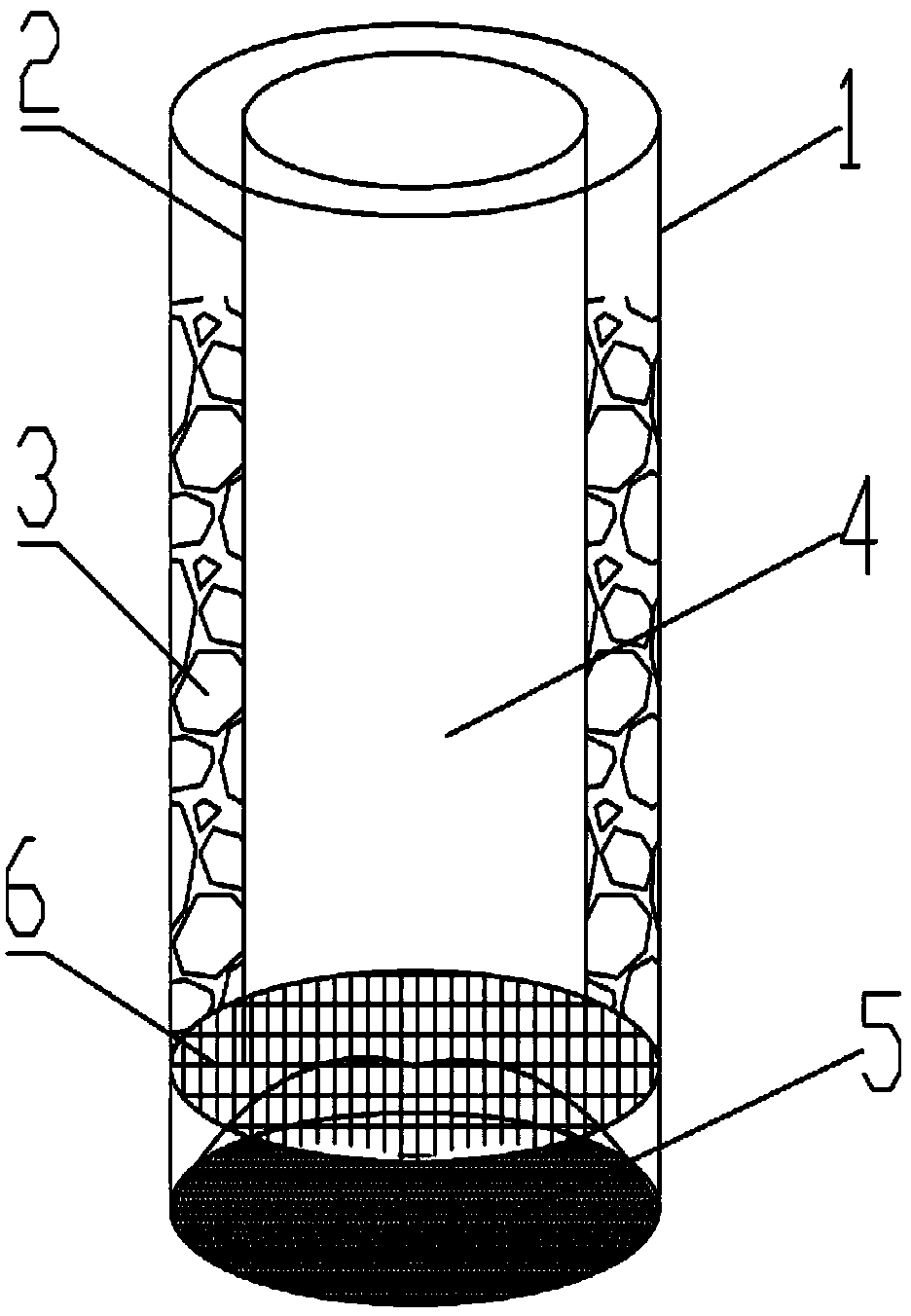

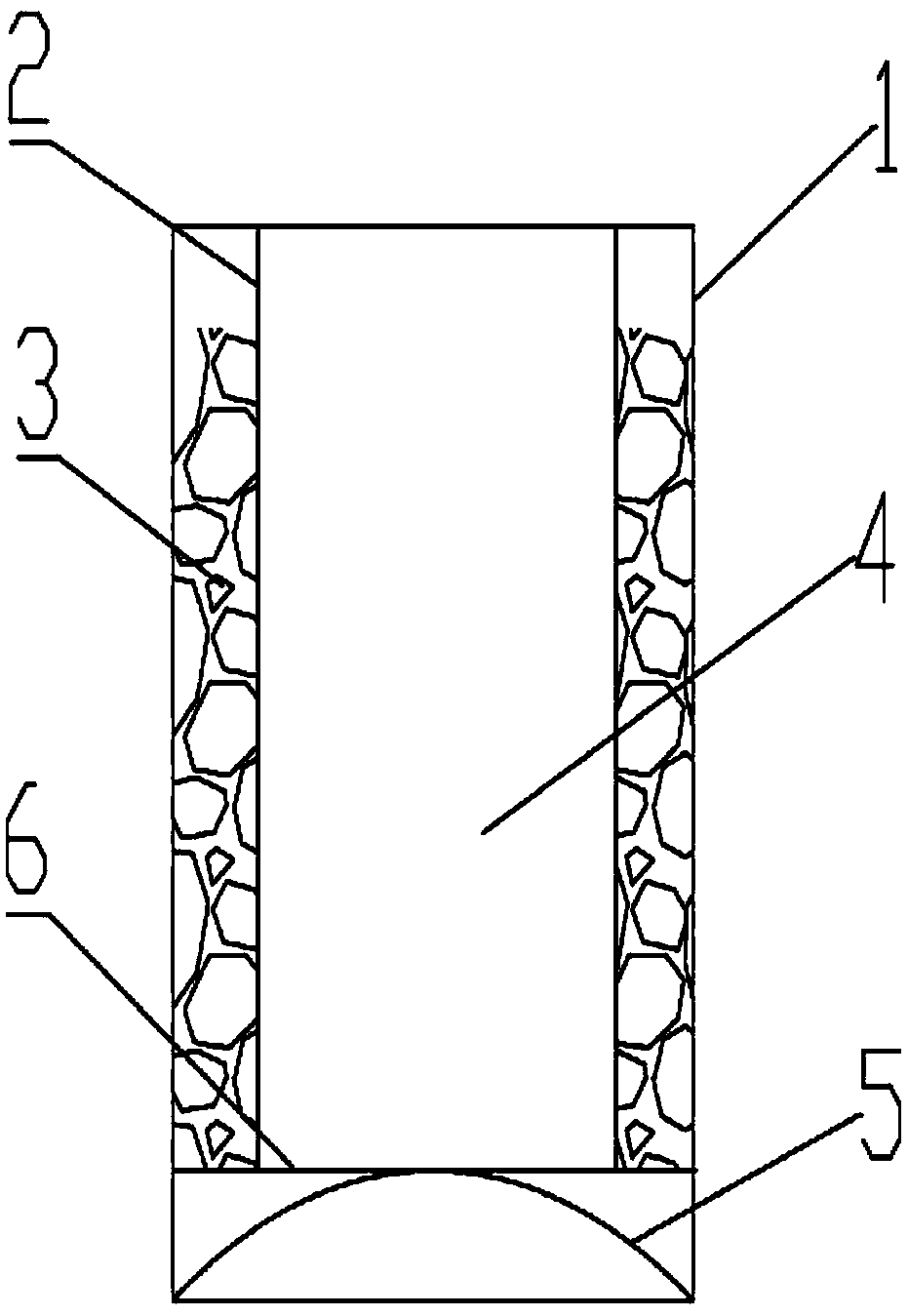

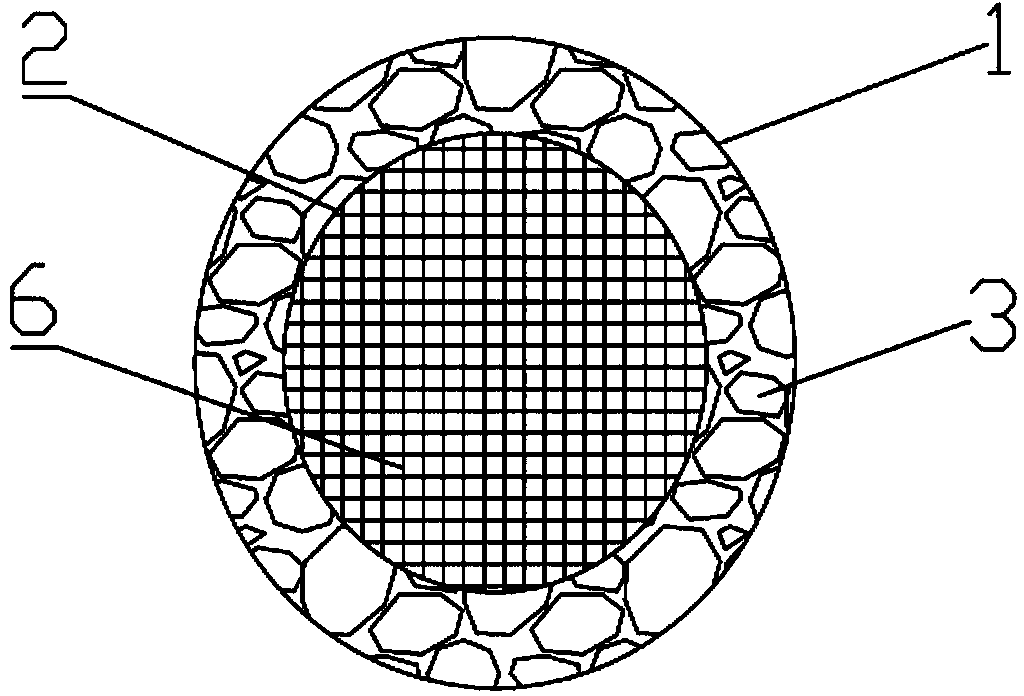

[0023] The test device is a cylindrical reactor made of plexiglass, with an inner diameter of 200mm, a height of 1.0m, and a total volume of 15L. The reactor cylinder is provided with a sampling port every 100mm. First, install a microporous aeration device at the bottom of the reactor. The aeration device is a sand table aeration disc with a diameter of 200 mm, which is the same as the inner diameter of the reactor. A circular plexiglass plate with fine holes is placed above the aeration disc to make the bottom of the reaction device Flat, uniform gas distribution throughout the reactor. Then encircle the fine grid into a column shape with a diameter of 140 mm, and fix it inside the reactor with a connecting bolt, parallel to the inner wall of the reactor. The aperture of the grid is 3 mm to prevent the filler from penetrating through the grid. Finally, the b

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap