Admission cam shaft of engine

A technology for intake camshafts and engines, applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as low torque at low speeds, insufficient engine power performance, etc., to achieve improved torque at low speeds, performance optimization, and improved power performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0009] The present invention will be further described below in conjunction with the description of the drawings and the specific embodiments.

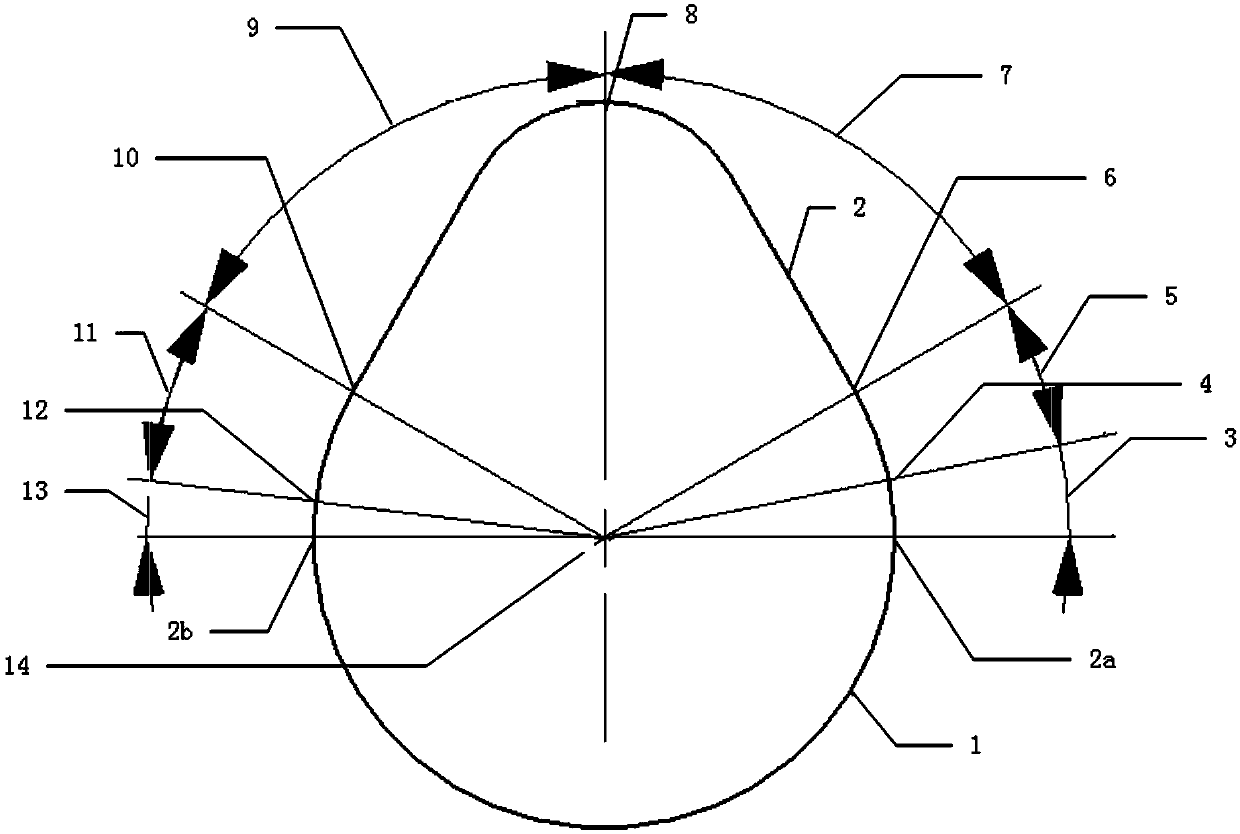

[0010] Such as figure 1 As shown, the profile of the camshaft includes a base circle (1) and a cam lobe (2). The center of the base circle (1) and the radial center of the cam lobe (2) coincide with the cam center (14) , And the two end points of the base circle coincide with the two end points of the cam peach, and the two end points of the cam peach are the opening end point (2a) and the closing end point (2b); the cam peach (2) ) Also includes the starting point of the buffer section (4), the point of completely eliminating valve clearance (6), the maximum valve lift point (8), the valve closing point (10), and the end point of closing the buffer section (12); The radius of the circle (1) is 15-17mm, the maximum lift of the cam is 7-8mm; the lift of the cam buffer section is 0.2-0.4mm; between the opening end point (2a) and the start po

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap