Wheat-steeping groove hanging device

A malt soaking tank and leveling machine technology is applied in the preparation of malt, beer brewing, biochemical equipment and methods, etc., to achieve the effects of reliable use, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

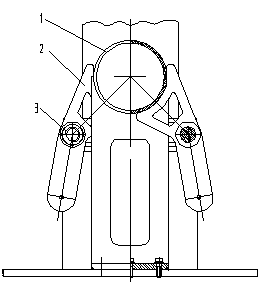

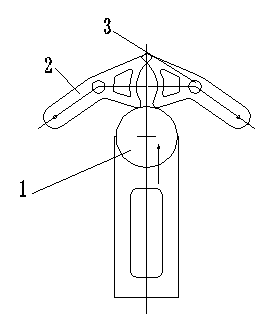

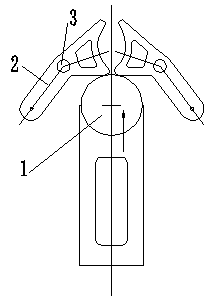

[0011] The hanging device of the present invention includes a hanging shelf 1 which is arranged on the upper part of the lifting shaft of the leveling machine. Hanging clips 2 are symmetrically distributed on both sides of the hanging shelf 1. The two hanging shelves 2 are rotated and arranged when the hanging shelf 1 is upward. It is rotated and pushed away during movement, the pivot point 3 of the hanging clip 2 is arranged in the middle of the hanging clip 2, and the upper supporting surface of the hanging clip 2 is arranged correspondingly to the outer contour of the hanging portion 1.

[0012] The mating surfaces of the hanging portion 1 and the supporting surface are circular.

[0013] The movement process of the hanging device of the present invention is as follows: when the hanging device is needed, 1) the lifting shaft moves upwards, and the two hanging clips 2 are pushed outward respectively. Since the hanging portion 1 is circular in cross section, it rises When moving, the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap