Tubular evaporator with two ends for dividing and gas guiding

A shunt tube and evaporator technology, applied in the direction of evaporator/condenser, refrigeration components, refrigerators, etc., can solve the problems of affecting the heat transfer performance of the evaporator, the performance of the refrigeration system, and the drying of the tube, and achieve simple structure and processing. Easy assembly and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

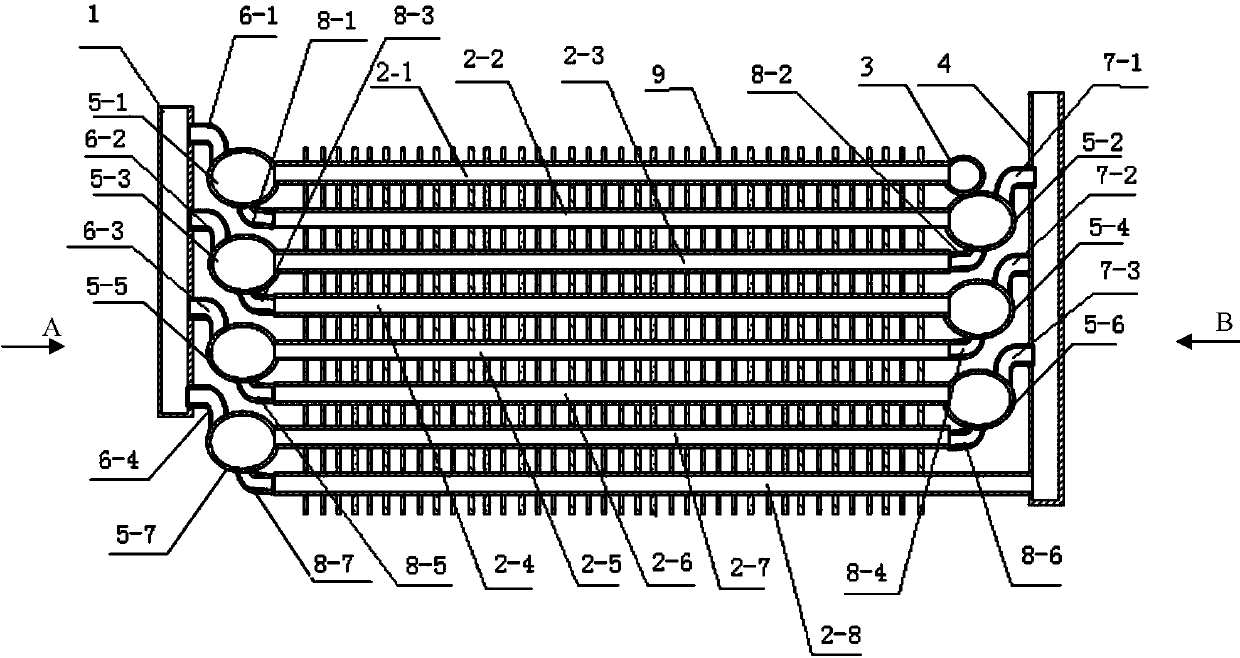

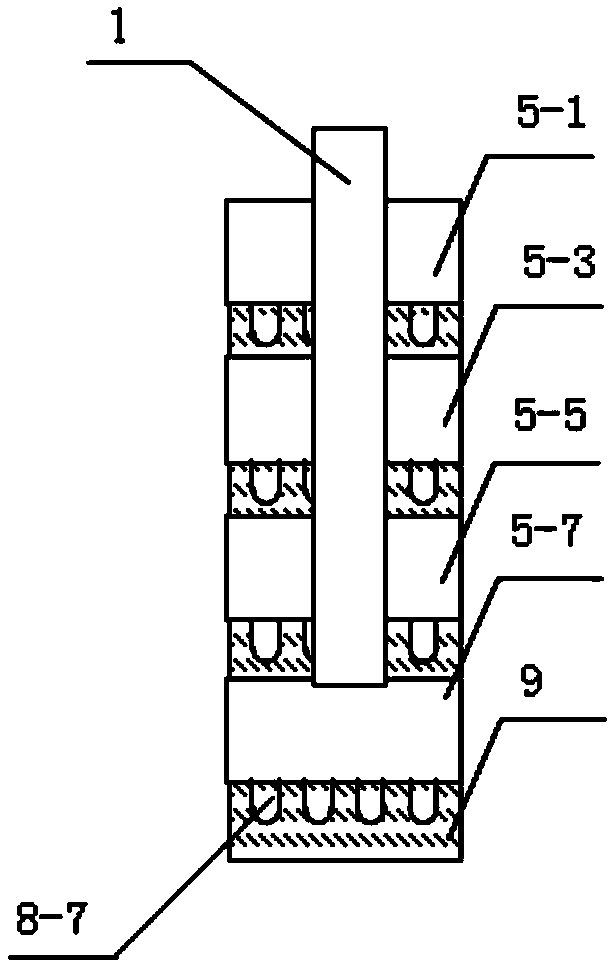

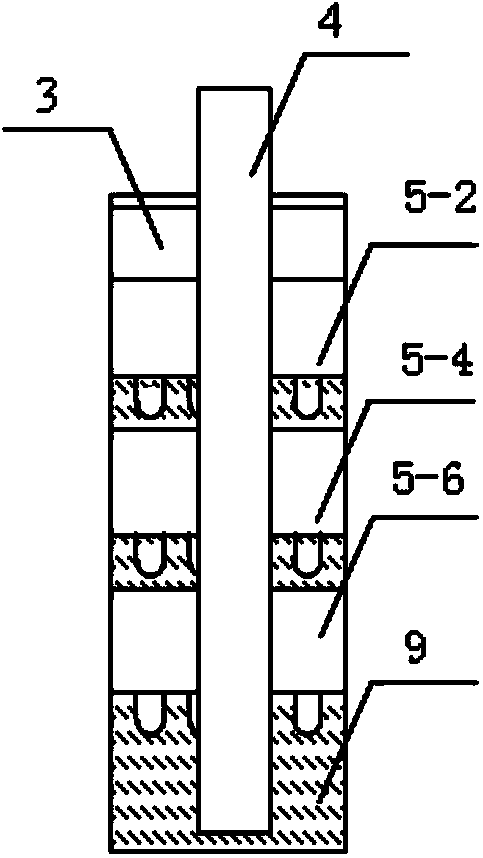

[0017] The tubular evaporator with both ends splitting and air-introduction of the present invention is a structure in which an exhaust part is added to the structure of the existing tubular evaporator. Including multiple rows of heat exchange tubes, one end of the refrigerant inlet of the heat exchange tube in the uppermost row is connected to the liquid distribution pipe, and one end of each row of the heat exchange tubes used as the refrigerant inlet is respectively connected to a liquid elbow; the last One end of the refrigerant outlet of the heat exchange tubes in the lower row is connected to the second air return pipe, and one end of the remaining heat exchange tubes in each row as the refrigerant outlet is respectively connected to a closed shunt pipe; The corresponding branch pipe is connected with the liquid elbow to form a con

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap