Method for preparing cooled agglomerated pellets by using dry method electric fly ash of converter gas

A technology for converter gas and cold-solidified pellets is applied in the field of converter gas dust removal and ash treatment, which can solve the problems of high pulverization rate and high manufacturing cost, and achieve the effects of reducing production cost, smelting cost and manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] The following specific embodiments will further clarify the present invention. It should be understood that the following specific embodiments are only used to illustrate the present invention and not to limit the scope of the present invention.

[0020] The invention discloses a method for manufacturing cold solid pellets by using converter gas dry electro-dedusting ash, which includes the following steps:

[0021] a. Digest the converter gas dry electric dust removal ash, the quality of the water added in the digestion treatment is 8-12% of the converter gas dry electric dust removal ash quality, and the digestion time is 14.5-15.5 hours;

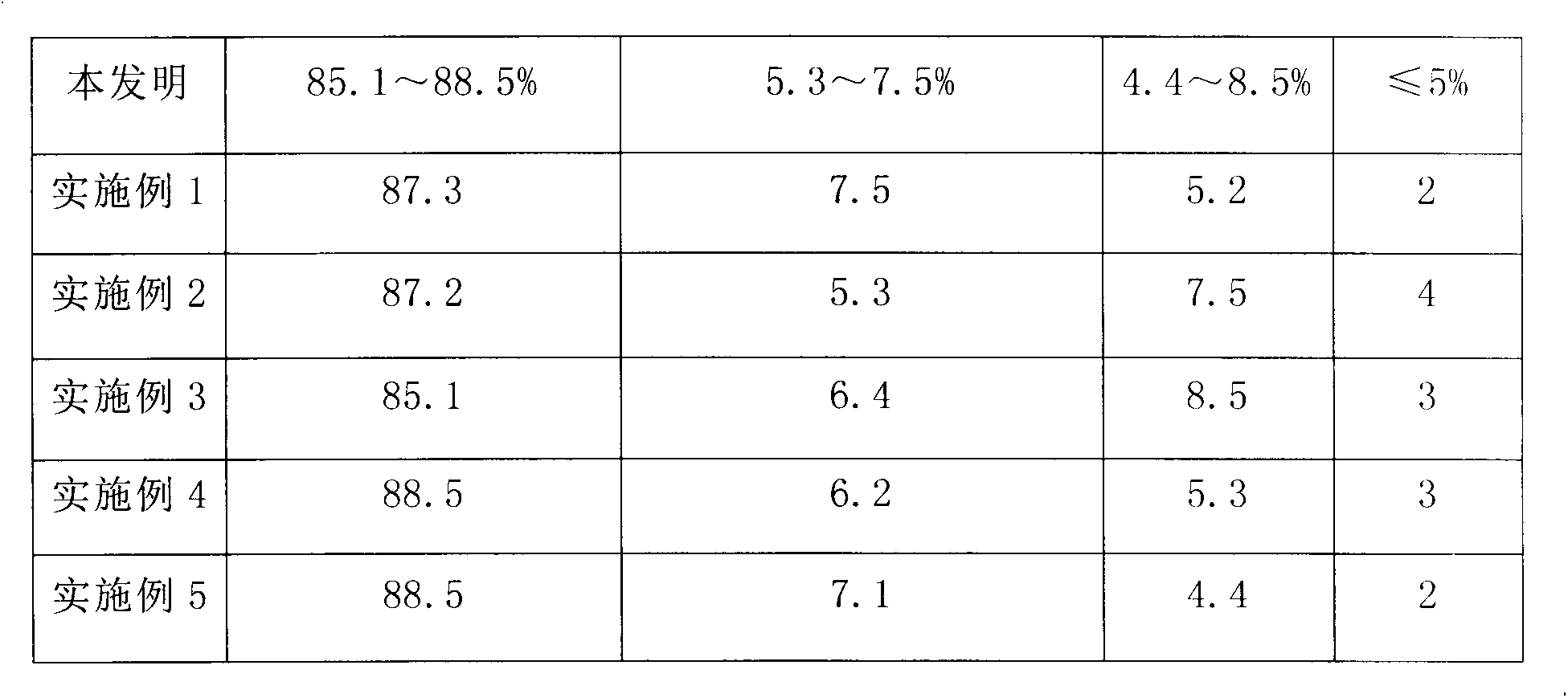

[0022] b. Add a 12% sodium polyacrylamide aqueous solution to the converter gas dry electric dust removal ash after digestion and stir to form a uniform mixture. The mass percentage of the components of the mixture is: converter gas dry electric dust removal ash 85.1 to 88.5%, 5.3 to 7.5% of sodium polyacrylamide aqueous solution, and 4.4 to

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap