Universal-regulation lifting device for clamping and lifting precision equipment or cylinder

A technology of precision equipment and universal adjustment, applied in portable hoisting devices, hoisting devices, etc., can solve the problems of safety hazards that cannot be adjusted arbitrarily, complex structure, large volume and weight, etc., to achieve smooth movement and self-adaptive guidance, Guaranteed safety and good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

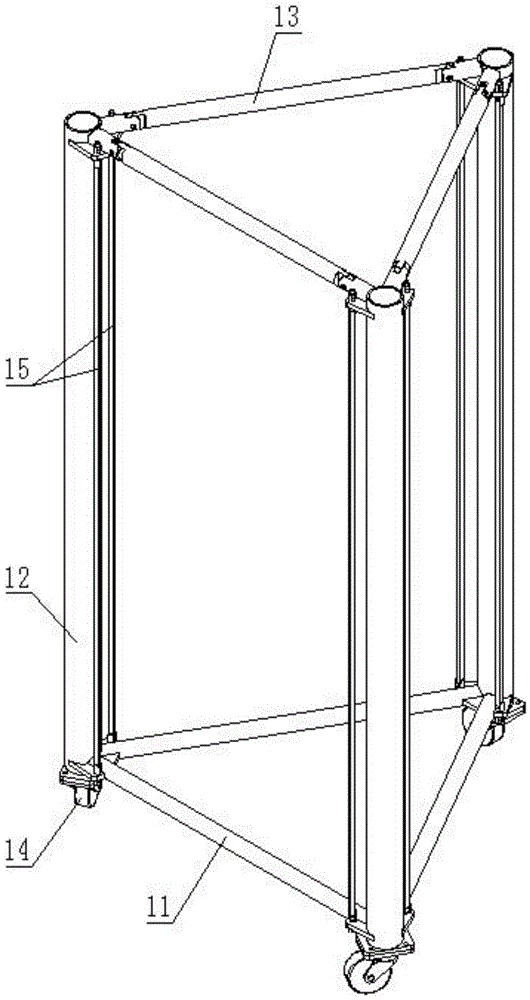

[0042] Embodiment: When in use, first remove the top beam 13 in the gantry 1, put the climbing mechanism 4 downward from the top of the gantry 1, wind the chain 15 around the sprocket 404 by pressing the sprocket 406, and then lock Tighten the bolts at both ends of the chain 15 to ensure that the chain 15 is in a tensioned state, then adjust the pre-tension spring 403 to tighten the support link 402 to ensure that the angle between the support link 402 and the housing 413 is less than 90°, and ensure that the guide The wheel 401 is in close contact with the inside of the column 12 .

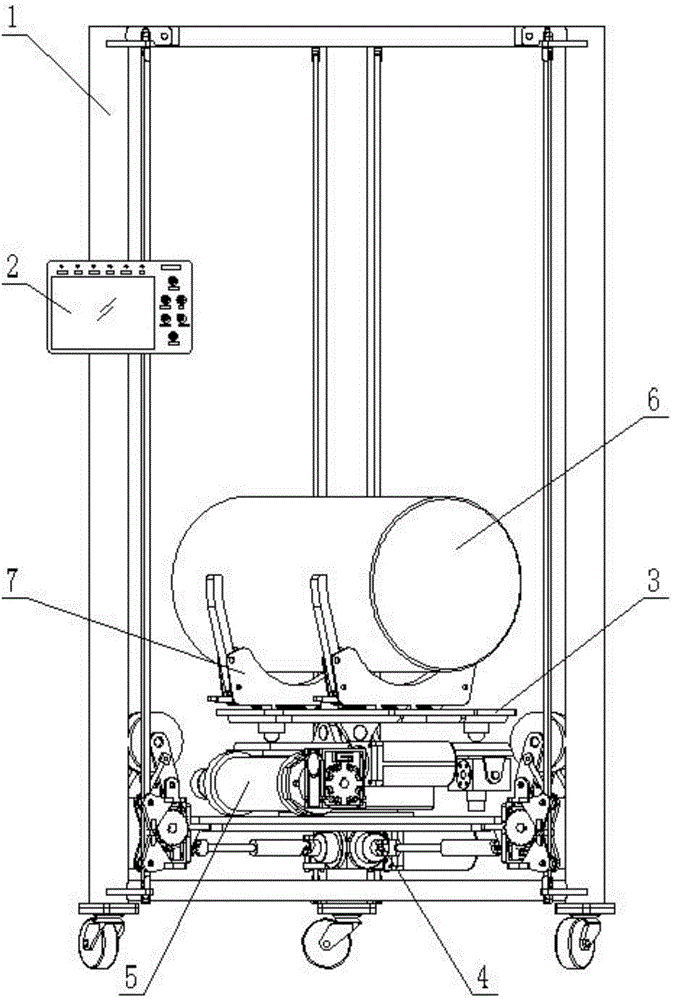

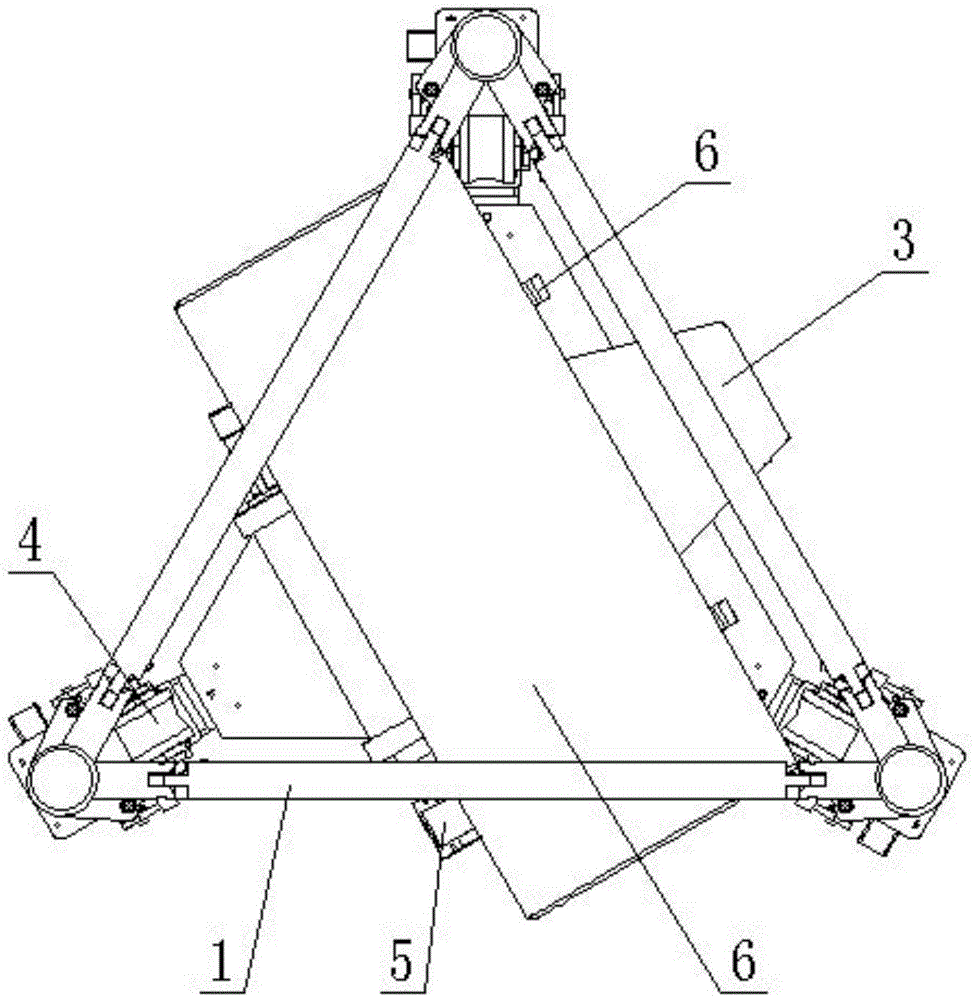

[0043] After the above installation is completed, it is necessary to install the rotary platform 5, the attitude adjustment mechanism 3 and the clamping mechanism 7 as follows: figure 1 In the state shown, first the rotary platform 5 is installed on the top of the climbing mechanism 4, the base 54 is affixed to the mounting bracket 408 in the climbing mechanism 4, and then the bottom plate 33 in the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap