Method for constructing large-span continuous steel trussed girder bridge under low height limit condition

A technology of steel truss girder bridge and construction method, which is applied to bridges, bridge materials, bridge construction, etc., can solve the problems of continuous steel truss girder bridges that cannot be constructed and steel truss girder girders cannot be lifted by hoisting equipment, etc., and achieves high strength and rigidity. , to ensure the effect of safety and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0037] The construction method of the large-span continuous steel truss bridge under the condition of low limit height in the embodiment of the present invention comprises the following steps:

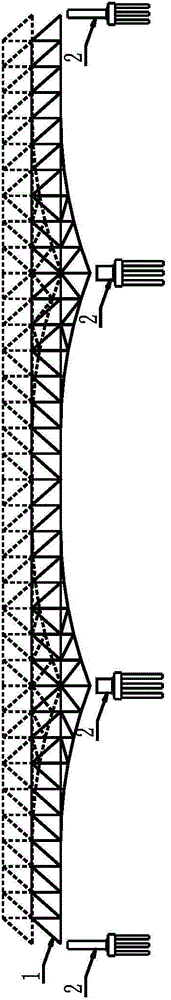

[0038] S1: see figure 1 As shown, at the design positions of all the piers of the long-span continuous steel truss girder bridge, the poured pier body 2 forming the lower half of the pier is poured, and the steel truss girder 1 is erected on the top of the poured pier body 2 until it is closed, and then transferred to Step S2.

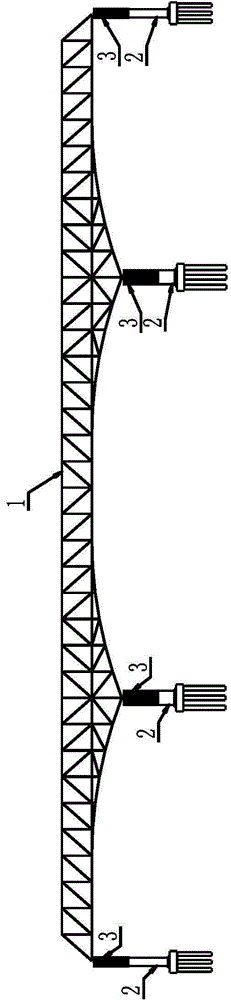

[0039] S2: see figure 2 As shown, the assembled steel truss girder 1 is lifted to the design elevation on the top of the poured pier body 2; while the steel truss girder 1 is lifted, the poured pier body 2 is alternately poured in sections and regions. The pier body 3 supports the steel truss girder 1 through the poured pier b

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap