Polyurethane guardrail

A polyurethane and guardrail technology, used in roads, buildings, road safety devices, etc., can solve the problems of damage to shock absorbers, no shock absorbers, waste of resources, etc., to reduce usage, avoid corrosion, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

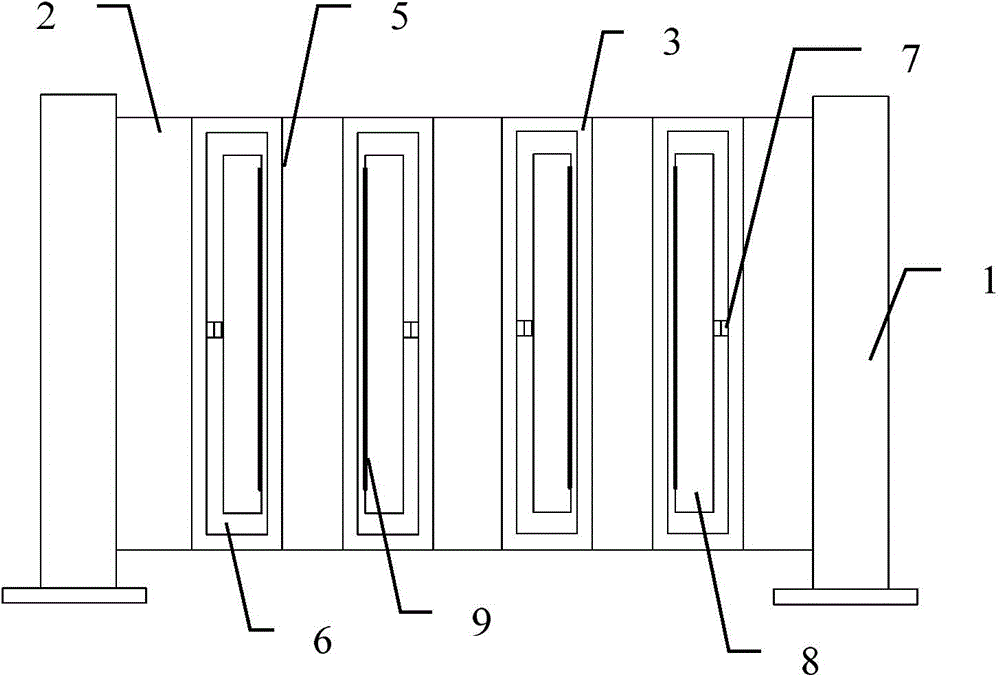

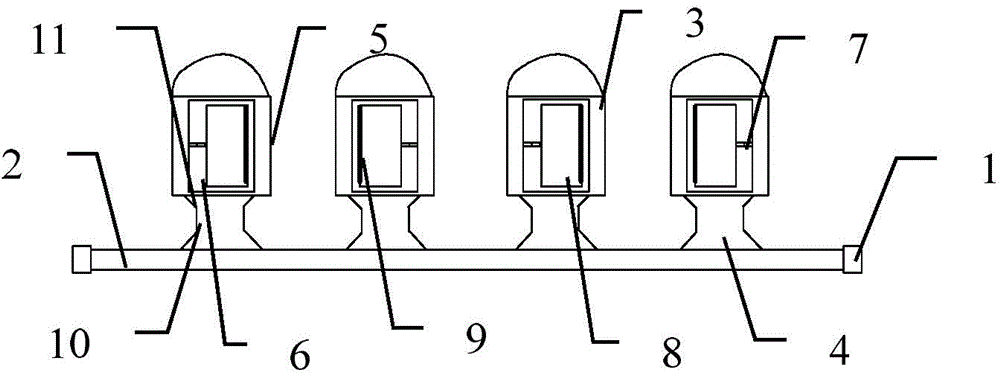

[0018] Such as figure 1 and figure 2 As shown, the present invention provides a polyurethane guardrail, comprising:

[0019] Pillar 1, a metal guardrail matrix 2 is fixed between two adjacent pillars, and the metal guardrail matrix mainly prevents the vehicle from rushing to other lanes when it hits the guardrail. The pillars are fixed on the ground through the fixtures, the distance between the two pillars is 10-15 meters, and the two ends of the metal guardrail matrix are welded on the two pillars.

[0020] A plurality of polyurethane protective sheets 3 are dispersedly arranged on the metal guardrail base, and two adjacent polyurethane protective sheets are arranged in parallel, which can be arranged horizontally or vertically. The polyurethane buffer sheet can be used whe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap