An Overtight Protective Shear Ring Locking Mechanism

A technology of locking mechanism and shear ring, which is applied in the direction of fluid pressure actuating device, etc., can solve problems such as equipment failure, indentation on the surface of shaft and rod parts, and lack of limit ability, so as to achieve good clamping force and prevent damage , design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

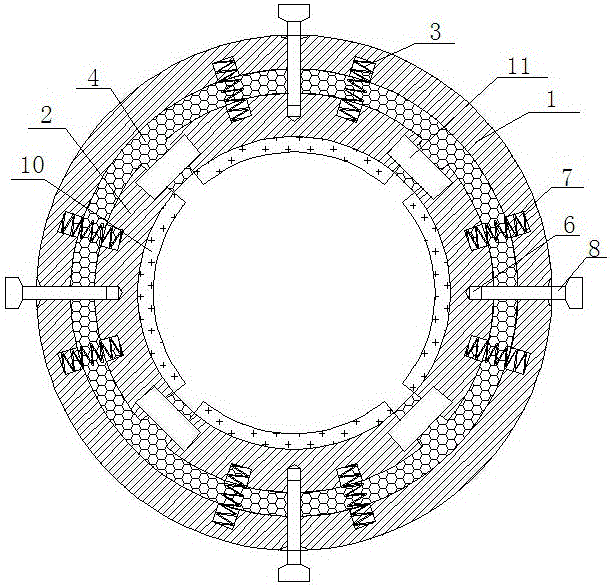

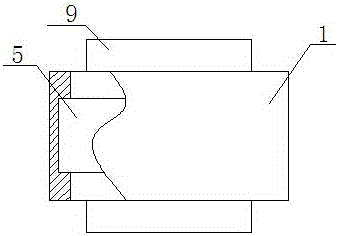

[0014] like figure 1 and 2 The above-mentioned over-tightening protection type shear ring locking mechanism includes a positioning plate 1, a pressing block 2, a return spring 3 and an elastic positioning block 4. The positioning plate 1 is cylindrical, and a position groove 5 is set on its inner surface. .

[0015] In this embodiment, the pressing blocks 2 are at least 4 and are all arc-shaped. After the pressing blocks 2 are connected in sequence, they can form a perfect circle concentrically distributed with the positioning plate 1. The pressing blocks 2 are evenly distributed on the inside the positioning groove 5 and slidingly connected with the positioning groove 5, and the middle point of the outer surface of the pressing block

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap