Large-size liquid crystal panel detection device

A liquid crystal panel and detection device technology, applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of low detection efficiency, poor detection effect, no alignment device, handling device, etc., achieve high detection efficiency, simple operation, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

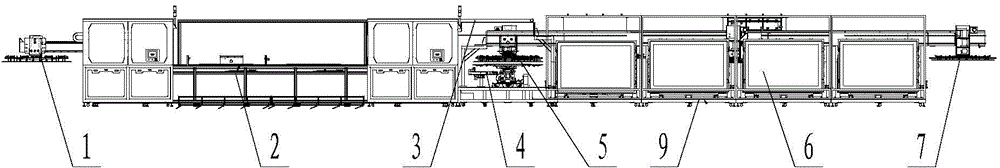

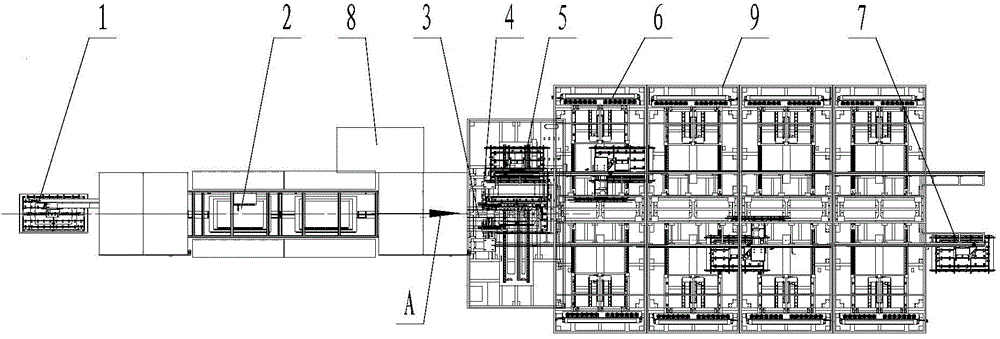

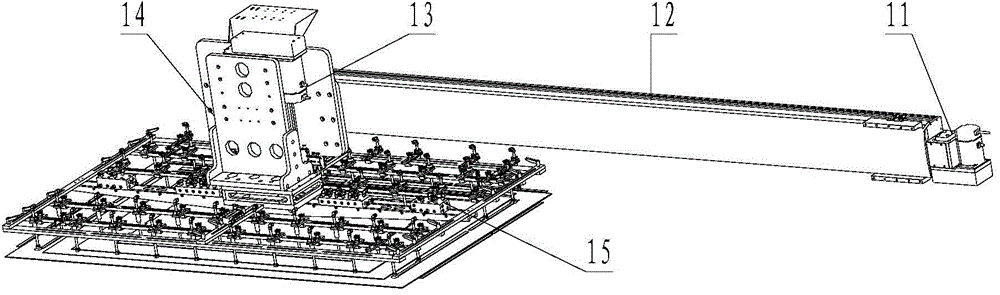

[0028] Such as figure 1 , figure 2 As shown, the present invention comprises a frame 9, on which the second feeding device 1, the assembly line device 2, the first feeding device 3, the turntable 5 and the turning mechanism are sequentially installed along the axial direction A, and the CCD camera moving device 4 Located under the support plate of the turntable 5, the turning mechanism includes a plurality of turning devices 6 installed on the frame 9 and symmetrically distributed on both sides of the axial direction A. Guide rails 94 are respectively provided on the two guide rails, and a plurality of pick-and-place devices 7 that can move along the slide rails are respectively installed. The turntable 5 is movably installed on th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap