Lifting device for garbage compactor

A technology of garbage compressor and lifting device, which is applied in the direction of garbage conveying, garbage collection, storage device, etc., can solve the problems of long working stroke, large working space, and high operating cost, and achieves reduced working pressure, stable unloading operation, and reduced operating costs. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

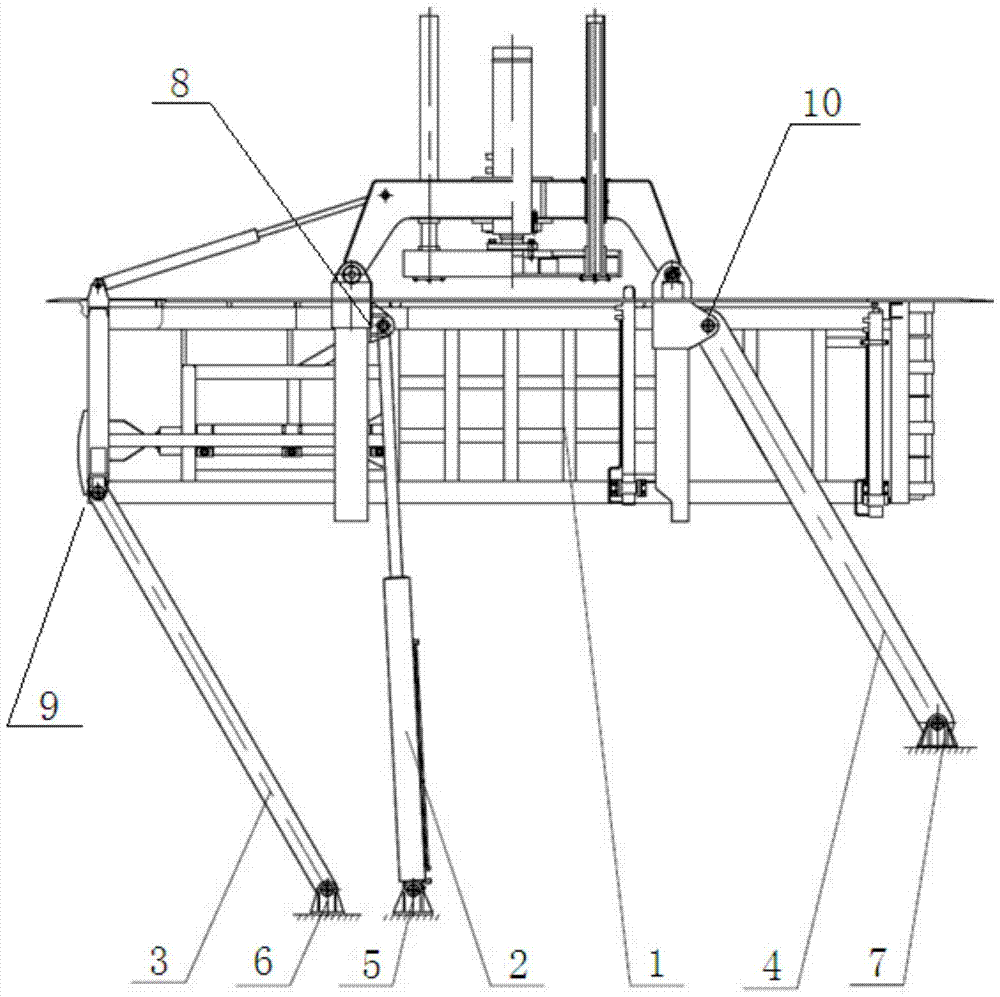

[0020] Such as figure 1 As shown, a lifting device for a garbage compressor includes a compressed garbage bin 1, a lifting cylinder 2, a front pull rod 3, a swing rod 4, a lower support for the lifting cylinder 5, a lower support for the front pull rod 6, and a lower support for the swing rod Seat 7; the box body of the compressed trash can 1 is a rectangular parallelepiped structure, the piston of the lifting cylinder 2 is hinged with the first hinge interface 8 located in the body of the compressed trash can 1, the cylinder body of the lifting cylinder 2 and the lifting cylinder The lower support 5 is hinged; one end of the front pull rod 3 is hinged with the second hinge interface 9 located in the box of the compressed trash c

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap