Anti-dropping expansion screw with easily-detachable nut

An expansion screw, easy-to-remove technology, applied in the directions of pins, connecting components, mechanical equipment, etc., can solve the problems that the nut cannot be disassembled, the screw falls and hurts people, etc., and achieves the effect of easy disassembly, simple operation, and not easy to fall and hurt people.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] Example 1

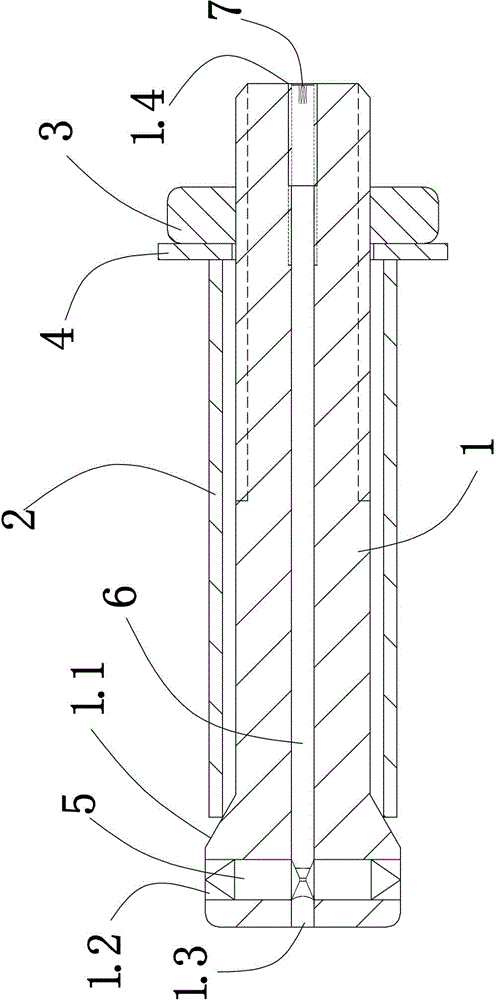

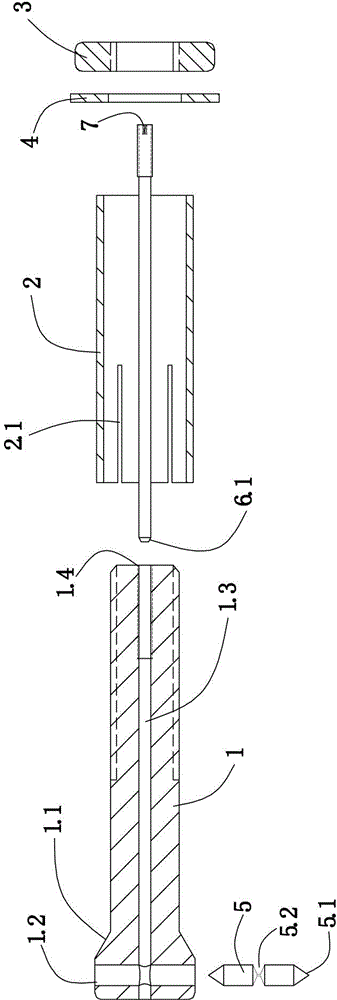

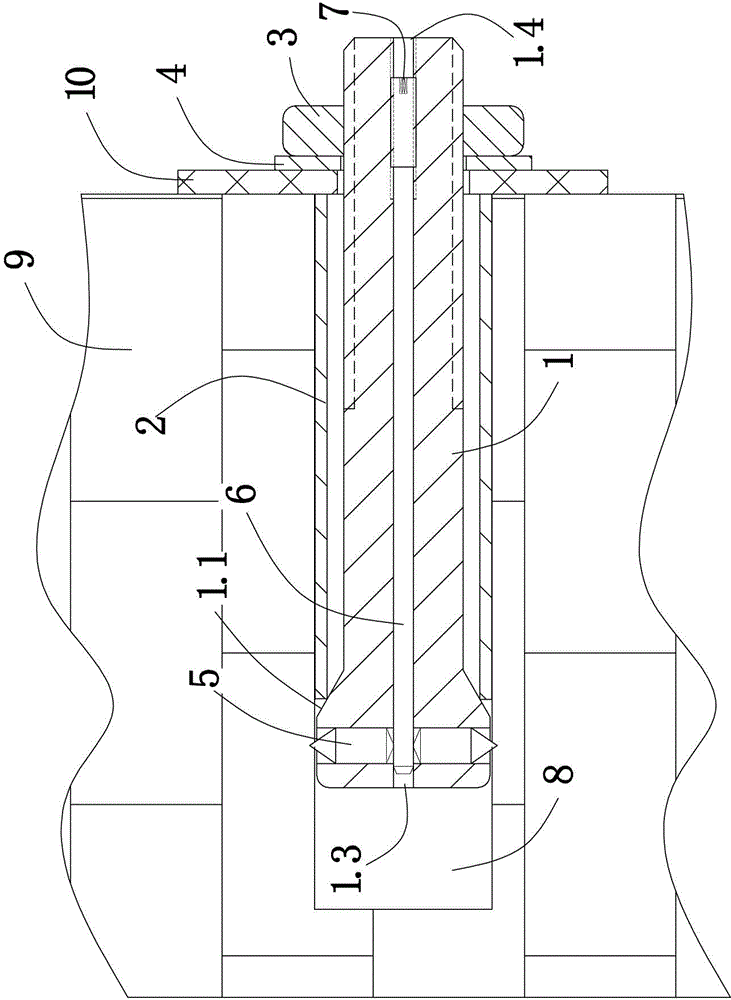

[0014] 1. In (attached figure 1 ), (attached figure 2 ) In the illustrated embodiment 1, it includes a screw, an expansion sleeve, a nut and a washer. One end of the screw 1 is provided with a thread, the other end is provided with a positioning shaft 1.5, and the positioning shaft 1.5 is provided with a through positioning hole in the axial middle. 1.2. There is a positioning pin 5 in the positioning hole 1.2. The outer circle of the positioning pin 5 is provided with a trapezoidal groove 5.2 with a large outer diameter and a small inner circle. The trapezoidal groove 5.2 is provided with a pre-break shaft 5.3. The longitudinal center of the screw 1 is provided with a positioning hole 1.2 Extrusion rod holes 1.3 passing through each other perpendicularly, the extrusion rod hole 1.3 is located at the threaded end of the screw 1 with a screw hole 1.4, the extrusion rod hole 1.3 is provided with an extrusion rod 6, and one end of the extrusion rod 6 is provided with

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap