Heat exchanger for reducing butadiene autopolymer and using method thereof

A butadiene and self-polymer technology, applied in the field of butadiene heat exchange devices, can solve the problems of butadiene self-polymer aggregation, reduce butadiene self-polymer and other problems, so as to reduce adverse effects and improve production efficiency , the effect of prolonging the use cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

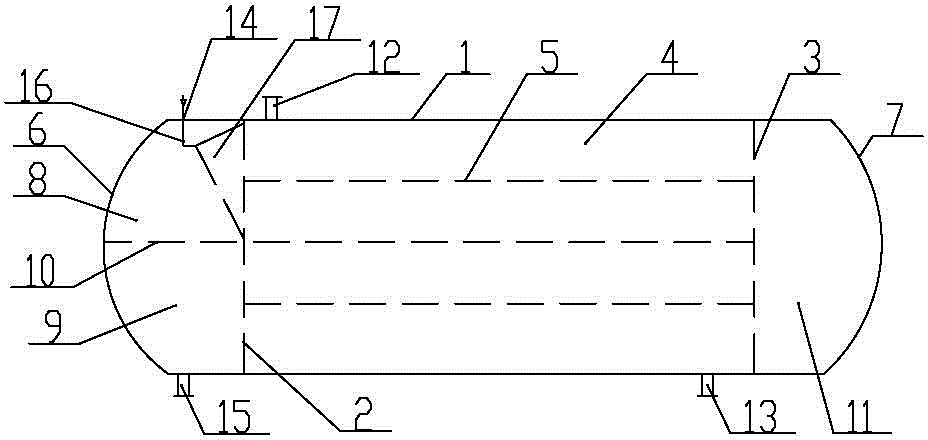

[0014] Embodiment 1: as attached figure 1 As shown, the heat exchanger for reducing butadiene autopolymer includes a shell 1, in which a left tube sheet 2 and a right tube sheet 3 are fixed from left to right, and the left tube sheet 2 and the right tube sheet A heat exchange chamber 4 is formed in the shell 1 between 3, and a row of tubes 5 is distributed in the heat exchange chamber 4. A left head 6 is fixed on the left part of the shell 1, and a right seal is fixed on the right part of the shell 1. The head 7 forms a left chamber between the left head 6 and the left tube plate 2, and the left chamber is fixed with a baffle 10 that divides the left chamber into an upper chamber and a lower chamber 9. There is a butadiene inlet 14 on the top of the corresponding housing 1, and an injection pipe 16 that divides the upper chamber into an inner chamber 17 and an outer chamber 8 is fixed at the butadiene inlet 14. The left ends of the tubes 5 are connected, the outer chamber 8 i

Embodiment 2

[0017] Embodiment 2: as attached figure 1 Shown, the using method of this heat exchanger that reduces butadiene autopolymer is carried out as follows: when butadiene is in the injection pipe 16, in the column pipe 5, in the right chamber 11 and the lower chamber 9 When more than one place forms self-polymer, butadiene is sent into butadiene inlet 14, injection pipe 16, inner chamber 17, column tube 5 above baffle plate 10, right chamber 11, baffle plate 10 in sequence The column tube 5 and the lower chamber 9 below, finally, butadiene and self-polymer are discharged through the butadiene outlet 15, wherein the pressure of the butadiene is 0.37MPa to 0.38MPa, and the temperature of the butadiene is 40°C To 42°C, the flow rate of butadiene is 5 cubic meters per hour to 14 cubic meters per hour.

[0018] In summary, the present invention can prevent the butadiene autopolymer from entering the dead corner in the heat exchange process, effectively prevent the accumulated butadie

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap