High-efficiency maintenance device for oil pipe

A high-efficiency technology for oil pipes, applied in the field of high-efficiency maintenance devices for oil pipes, can solve the problems of heavy materials, heavy workload, and long maintenance methods, and achieve the effect of saving operation time and reducing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

[0019] Such as figure 1 As shown, the high-efficiency oil pipe maintenance device includes a booster pump 1, a hose 2 and a nozzle 3. The booster pump can provide an electric drive pump with a pressure of 20MPa, a displacement of 170L / min, and a driving power of 75kw.

[0020] It also includes a drum 4 , a base 5 and a fixed frame 6 , the drum 4 and the booster pump 1 are both arranged on the base 5 , and the hose 2 is wound on the drum 4 . The base 5 is arranged on a fixed frame 6 , and the fixed frame 6 is provided with a suspension ring 7 . During work, shower nozzle 3 stretches in the oil pipe 8 that is maintained.

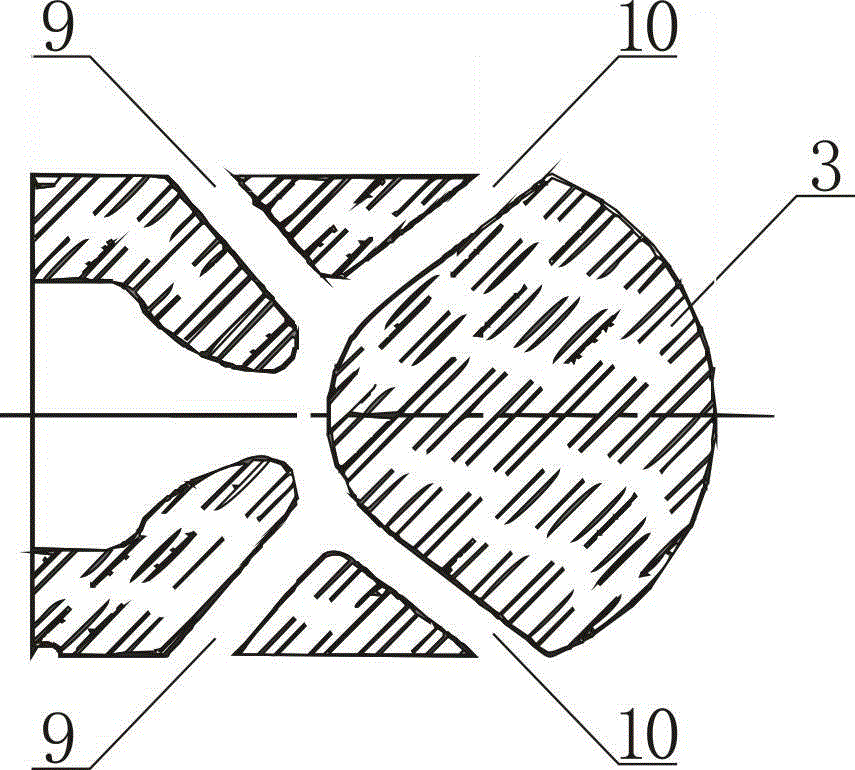

[0021] Such as figure 2 As sho

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap